Thermal sublimation transferring-printing coating pulp and method for carrying out thermal sublimation transferring-printing by using same

A technology of thermal sublimation and coating paste, applied in coating, copying/marking method, printing and other directions, can solve the problems of poor applicability of coating paste, unclear pattern texture, low color fastness, etc. Excellent outdoor aging resistance, clear pattern texture, high color fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

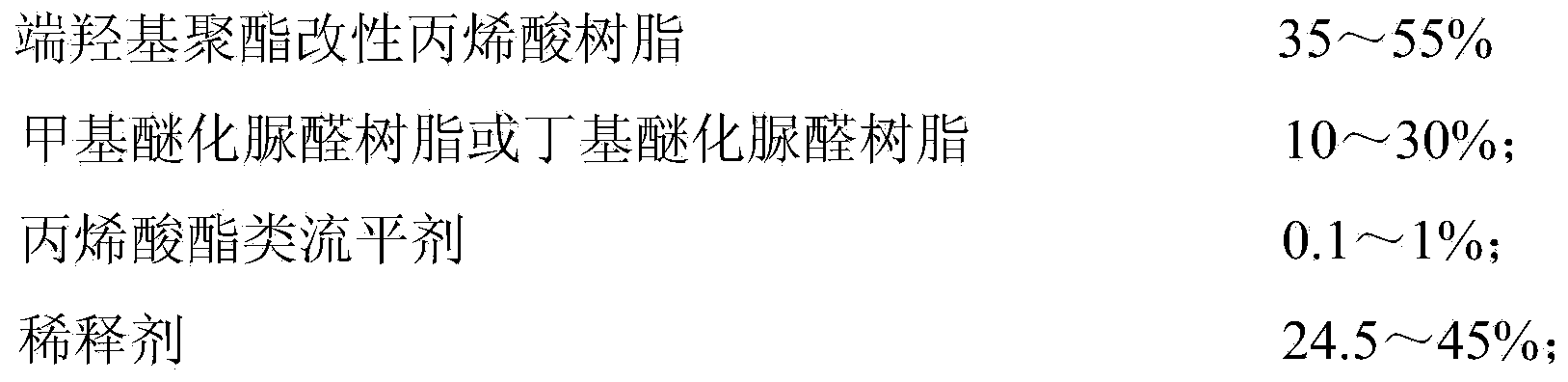

[0059] The coating slurry for thermal sublimation transfer provided in this embodiment includes the following components by mass percentage:

[0060]

[0061] The hydroxyl-terminated polyester modified acrylic resin has a solid content of 60±2% and an acid value of 3-5 mgKOH / g; the methyl etherified urea-formaldehyde resin has a solid content of 75±2% and an acid value of <1 mgKOH / g; the acrylic acid The number average molecular weight of the ester leveling agent is between 6,000 and 20,000, the glass transition temperature is below -20°C, and the surface tension is below 25 to 26mN / m.

Embodiment 2

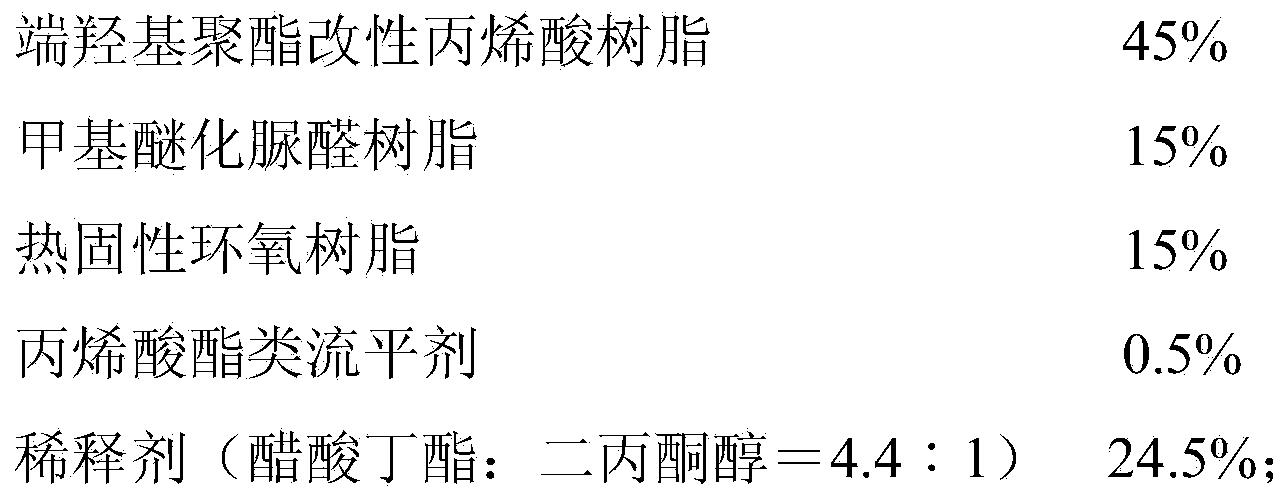

[0063] The coating slurry for thermal sublimation transfer provided in this embodiment includes the following components by mass percentage:

[0064]

[0065]

[0066]The hydroxyl-terminated polyester-modified acrylic resin has a solid content of 60±2%, and an acid value of 3-5mgKOH / g; the butyl etherified urea-formaldehyde resin has a solid content of 75±2%, and an acid value<1mgKOH / g; The number average molecular weight of the acrylate leveling agent is between 6,000 and 20,000, the glass transition temperature is below -20°C, and the surface tension is below 25 to 26mN / m.

Embodiment 3

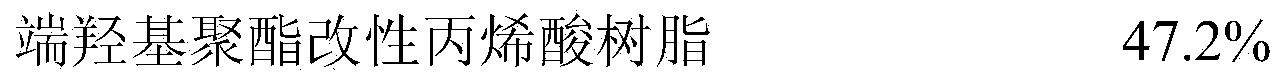

[0068] The coating slurry for thermal sublimation transfer provided in this embodiment includes the following components by mass percentage:

[0069]

[0070] The hydroxyl-terminated polyester modified acrylic resin has a solid content of 60±2% and an acid value of 3-5 mgKOH / g; the methyl etherified urea-formaldehyde resin has a solid content of 75±2% and an acid value of <1 mgKOH / g; the acrylic acid The number average molecular weight of the ester leveling agent is between 6,000 and 20,000, the glass transition temperature is below -20°C, and the surface tension is below 25 to 26mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com