Environment-friendly building water-based paint and preparation method thereof

A water-based coating and construction technology, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of lack of anti-pollution and antibacterial properties, etc., and achieve excellent mildew resistance and good waterproof performance, the effect of avoiding the use of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

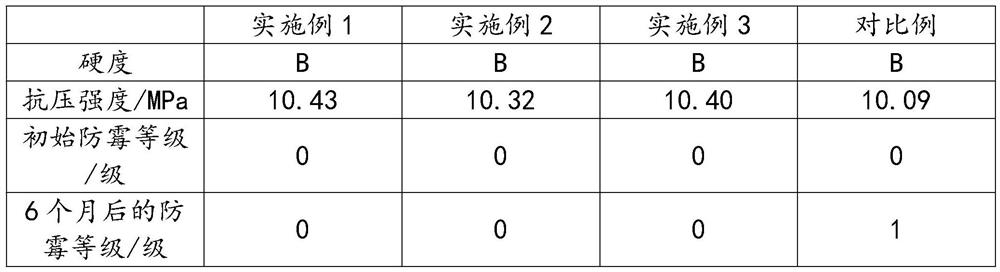

Embodiment 1

[0042] An environment-friendly water-based coating for buildings, comprising the following raw materials in parts by weight: 60 parts of silicone acrylic emulsion, 8 parts of perfluorosiloxane resin, 6 parts of composite filler, 1 part of coupling agent, 2 parts of anti-mildew compound, hydroxyethyl 2 parts of base cellulose, 0.9 parts of additives, 30 parts of pure water;

[0043] The water-based paint is made by the following steps:

[0044] The first step is to mix silicone acrylic emulsion, perfluorosiloxane resin, hydroxyethyl cellulose, pure water and half of the additives into the stirring tank according to the parts by weight, and stir at a stirring speed of 350r / min for 20min at room temperature , get base material;

[0045] The second step is to add the composite filler, coupling agent, anti-mold compound and the remaining half of the additives to the base material, stir and mix at 500r / min for 40min at room temperature, and then increase the speed to 2000r / min for ...

Embodiment 2

[0047] An environment-friendly water-based coating for buildings, comprising the following raw materials in parts by weight: 65 parts of silicone acrylic emulsion, 9 parts of perfluorosiloxane resin, 7.5 parts of composite filler, 1.2 parts of coupling agent, 2.5 parts of anti-mildew compound, hydroxyethyl Base cellulose 2.5 parts, additives 0.95 parts, pure water 35 parts;

[0048] The water-based paint is made by the following steps:

[0049] The first step is to mix silicone acrylic emulsion, perfluorosiloxane resin, hydroxyethyl cellulose, pure water and half of the additives into the stirring tank according to the parts by weight, and stir at 350r / min stirring speed for 25min at room temperature , get base material;

[0050] The second step is to add the composite filler, coupling agent, anti-mold compound and the remaining half of the additives to the base material, stir and mix at a speed of 500r / min for 45min at room temperature, and then increase the speed to 2000r / m...

Embodiment 3

[0052] An environment-friendly water-based paint for buildings, comprising the following raw materials in parts by weight: 70 parts of silicone acrylic emulsion, 10 parts of perfluorosiloxane resin, 9 parts of composite filler, 1.4 parts of coupling agent, 3 parts of anti-mildew compound, hydroxyethyl 3 parts of base cellulose, 1 part of auxiliary agent, 40 parts of pure water;

[0053] The water-based paint is made by the following steps:

[0054] The first step is to mix silicone acrylic emulsion, perfluorosiloxane resin, hydroxyethyl cellulose, pure water and half of the additives into the stirring tank according to the parts by weight, and stir at room temperature for 30 minutes at a stirring speed of 350r / min , get base material;

[0055] The second step is to add the composite filler, coupling agent, anti-mold compound and the remaining half of the additives to the base material, stir and mix at 500r / min for 50min at room temperature, and then increase the speed to 2000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com