High-efficiency low-toxicity moldproof inhibitor

A high-efficiency, low-toxicity, inhibitor technology, applied in the direction of disinfectants, biocides, fungicides, etc., can solve the problems of high economic cost, high toxicity of anti-mold inhibitors, and poor effect of inhibiting fungi, and achieve good technical effects and good Antifungal inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

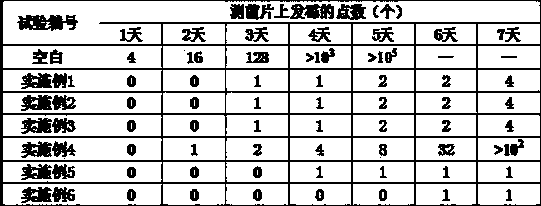

[0024] 92 grams of morpholine derivatives, 4 grams of fatty aldehydes, 9 grams of alkanolamide mixture, and 7 grams of solvent were evenly stirred to prepare Sample 1. Carry out anti-mildew inhibition test, the result is listed in Table 1.

Embodiment 2

[0026] 48 grams of morpholine derivatives, 20 grams of fatty aldehydes, 16 grams of alkanolamide mixture, and 16 grams of solvent were stirred evenly to prepare sample 1. Carry out anti-mildew inhibition test, the result is listed in Table 1.

Embodiment 3

[0028] 48 grams of morpholine derivatives, 22 grams of fatty aldehydes, 14 grams of alkanolamide mixture, and 16 grams of solvent were evenly stirred to prepare Sample 1. Carry out anti-mildew inhibition test, the result is listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com