Efficient preparation method and applications of food-grade acid ureases

An acid urease, food-grade technology, applied in the field of high-efficiency expression of acid urease, can solve problems such as limited application, and achieve the effect of solving residual problems and high-efficiency expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

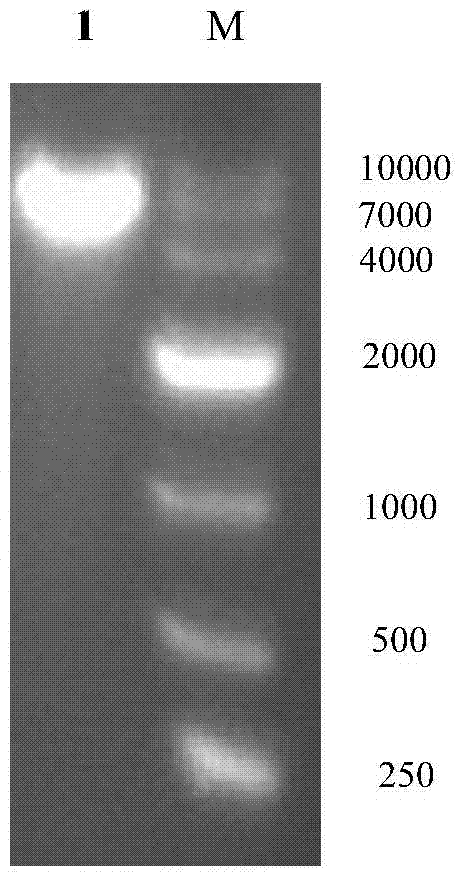

[0066] Embodiment 1: Cloning of acid urease gene

[0067] Genomic DNA of Lactobacillus reuteri CICC6124 was extracted according to the instructions of the Bacterial Genome Extraction Kit (OMEGA), and stored at -20°C for future use. According to the acid urease gene sequence published by NCBI (GenBank: AAPZ02000001.1, GI: 194454092-194454098), primers P1-P2 were designed to amplify the acid urease gene using Lactobacillus reuteri DNA as a template. The amplification conditions were as follows: 95°C, 5min, 1 cycle; 95°C, 30s, 55°C, 30s, 72°C, 5min30s, 30 cycles; 72°C, 5min, 1 cycle; 12°C, 5min, 1 cycle. Amplification system: Prepare a 50 μL system according to the instructions of the PrimeSTAR HS DNA Polymerase (TAKARA) kit. PCR products were recovered by 1% agarose gel electrophoresis, and the recovery method was carried out according to the instructions of the gel recovery kit (Thermo). The target gene obtained by PCR amplification was connected to the pMD19T-simple (TAKARA)...

Embodiment 2

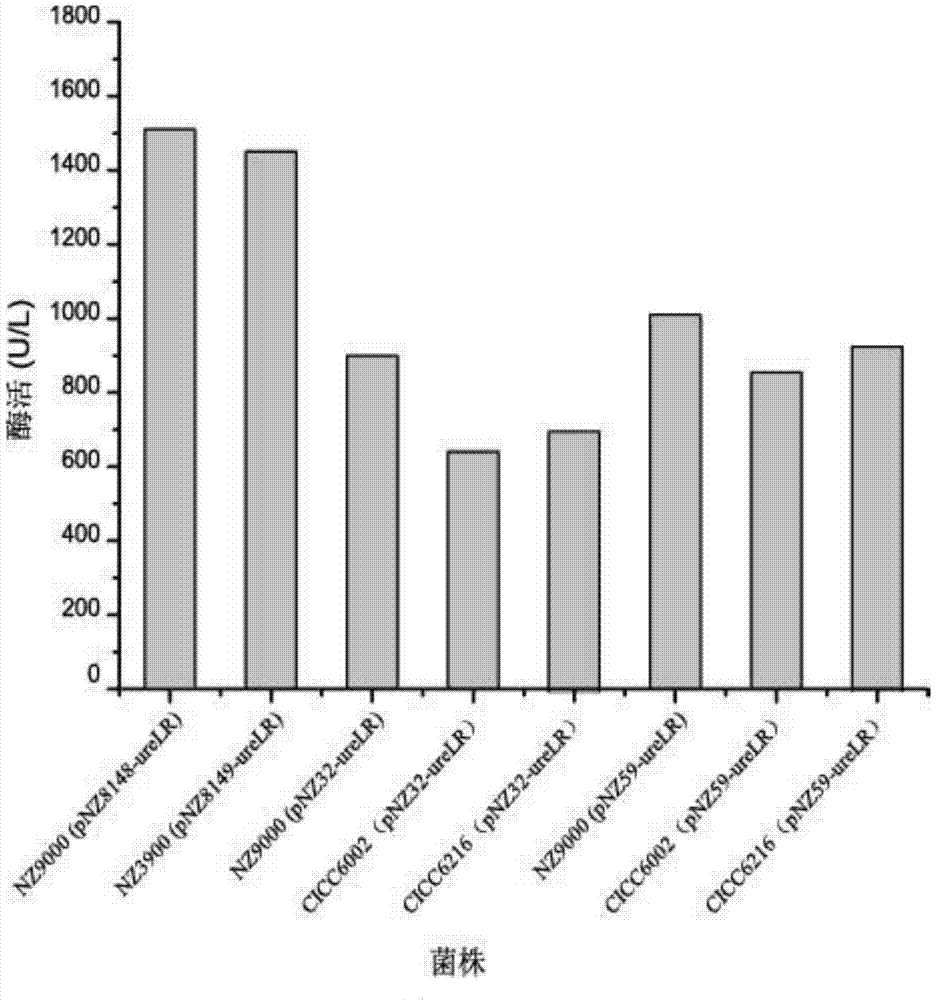

[0068] Example 2: Construction of recombinant lactic acid bacteria and high expression of acid urease

[0069] (1) The pMD19T-ureLR plasmid obtained by cloning in Example 1 was double-digested with NcoI and SacI restriction endonucleases (Thermo), and the target fragment was recovered by agarose gel electrophoresis according to the method in Example 1 after digestion . Ligate the recovered fragment of interest to the recovered Lactococcus lactis expression plasmid pNZ8148 after digesting with the same restriction enzymes (NcoI and SacI), transform into E.coil MC1061 competent cells, and spread it on a medium containing 10 μg / mL chloramphenicol On the prime LB plate, after some colonies grow, randomly pick a few colonies, use P3-P4 as primers, and identify positive clones by PCR, inoculate the correct colonies in LB liquid after colony PCR verification, and extract plasmids for sequencing verification after cultivation. The acid urease plasmid that was successfully ligated was...

Embodiment 3

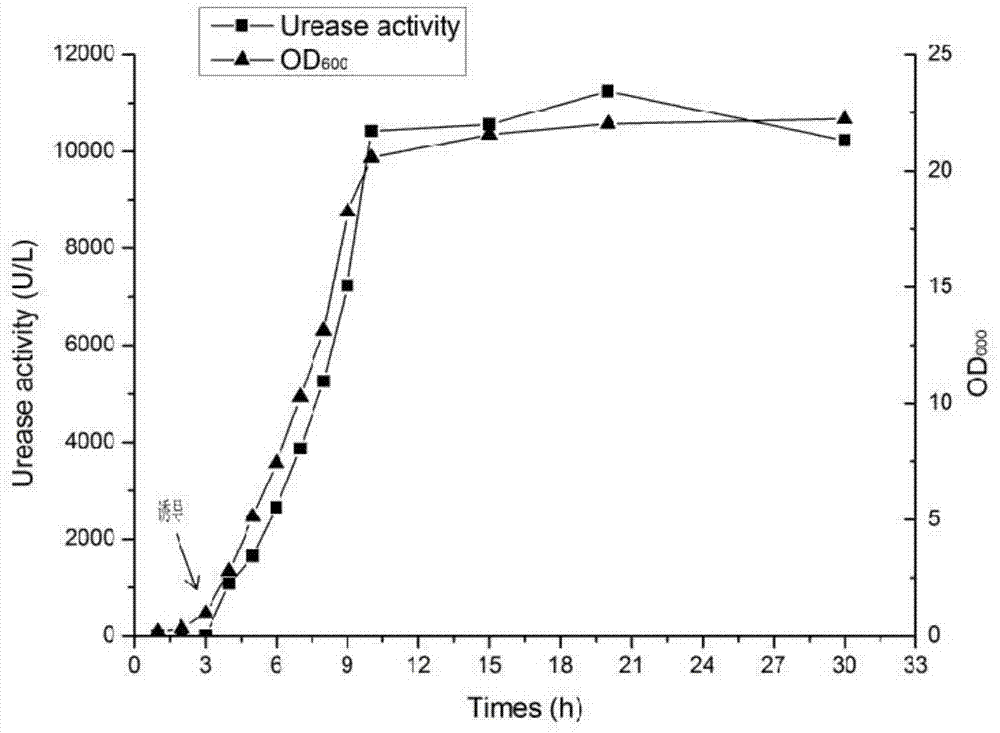

[0078] Embodiment 3: expression and purification preparation of food-grade acid urease

[0079] Fermentation experiments were carried out on the successfully constructed recombinant Lactococcus lactis strain NZ3900 (pNZ8149-UreLR). Seed liquid preparation: Inoculate the experimental strains into LM17 medium, fill 20 mL of liquid in a 50 mL shake flask, and culture at 30 ° C 16h; 1.5L medium in 3L fermenter (5% lactose, 1.5% peptone, 1% yeast extract, 1mM MgSO 4 , 0.1 mM MnSO 4 , 2.0mM NiCl 2 ), at a temperature of 30°C, cultured statically until the cell OD 600 1.0, add the inducer Nisin (final concentration 10ng / mL), induce the expression for 27h, and the enzyme activity reaches 10200U / L (such as image 3 shown). After collecting the bacteria by centrifugation, wash the bacteria twice with 300mL sterile distilled water, resuspend the bacteria in 200mL of 10mM Tris-HCl (pH7.4), 1mM EDTA solution, add 10mg of lysozyme, and treat in a water bath at 37°C for 3h, 300w, Sonica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com