Preparation method of nanosheet magnesium oxide catalyst and method for preparing diethyl carbonate by adopting catalyst

A technology of diethyl carbonate and flakes, which is applied in the field of preparation of nano-flaky magnesium oxide catalysts, can solve the problems of low catalyst activity such as carbamate decomposition, achieve good catalytic activity and stability, and the process is simple and easy , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mg(NO 3 ) 2 ·6H 2 O dissolved in deionized water, configured as 1.5mol / L Mg 2+ aqueous solution. 100mL1.5mol / L Mg 2+ Aqueous solution at 20°C with 2mol / L Na 2 CO 3 The precipitant was added dropwise to 50 mL of deionized water at the same time, and the pH was controlled at 10. After the precipitation was completed, the stirring was continued at 65°C for 3 hours, and then hydrothermally heated at 120°C for 10 hours. After hydrothermal treatment, the precipitate is filtered, washed with water until neutral, and then dried at 120°C for 10 hours. After drying, it is ground, and then calcined at 450, 600, and 750°C for 3 hours in an air atmosphere to obtain white magnesium oxide. The powders are recorded as MgO-A-450, MgO-A-600, and MgO-A-750, respectively, where 450, 600, and 750 represent the calcination temperature.

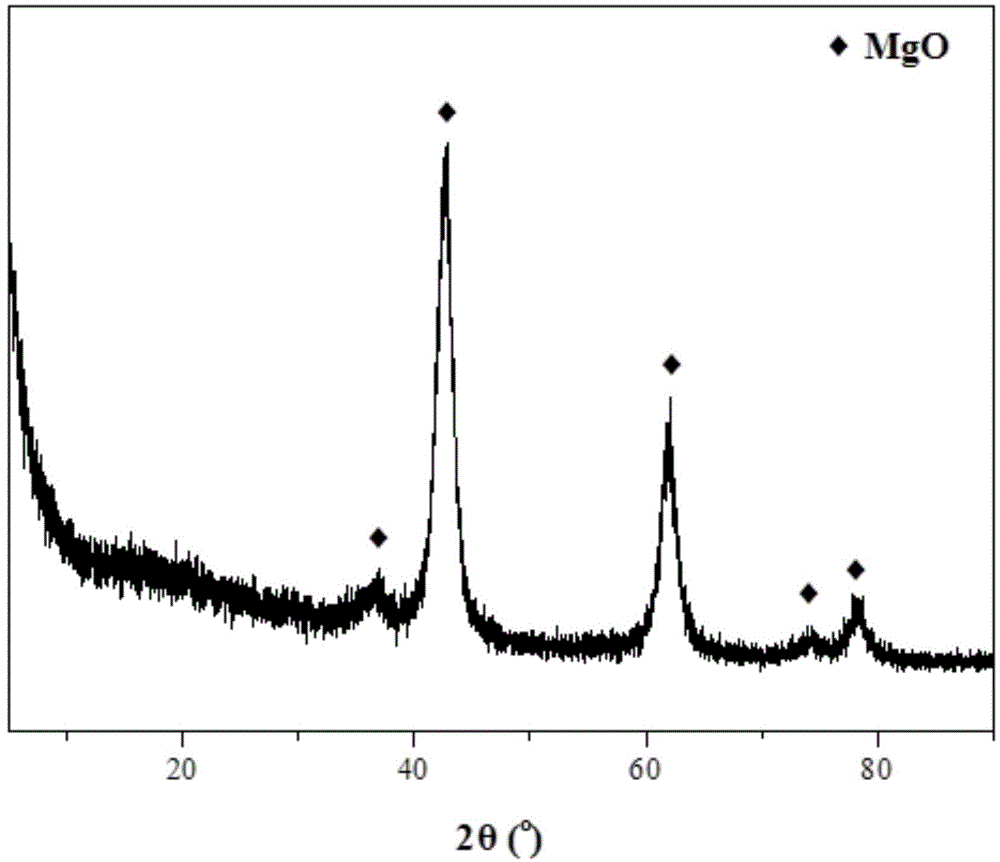

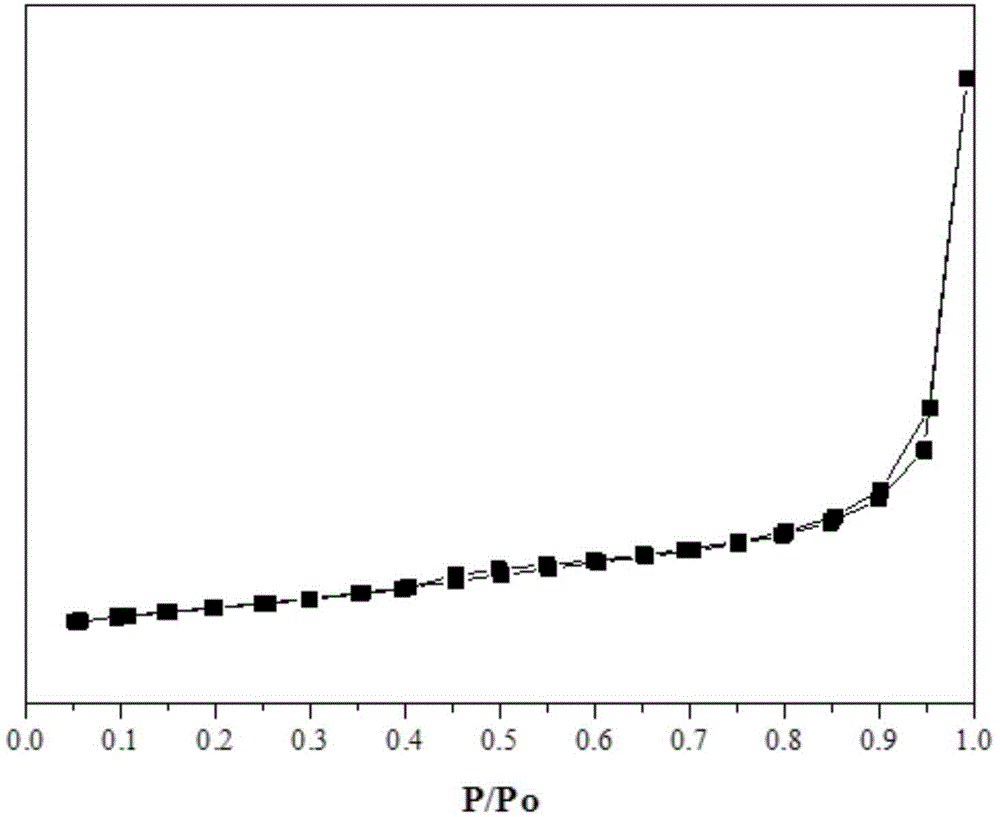

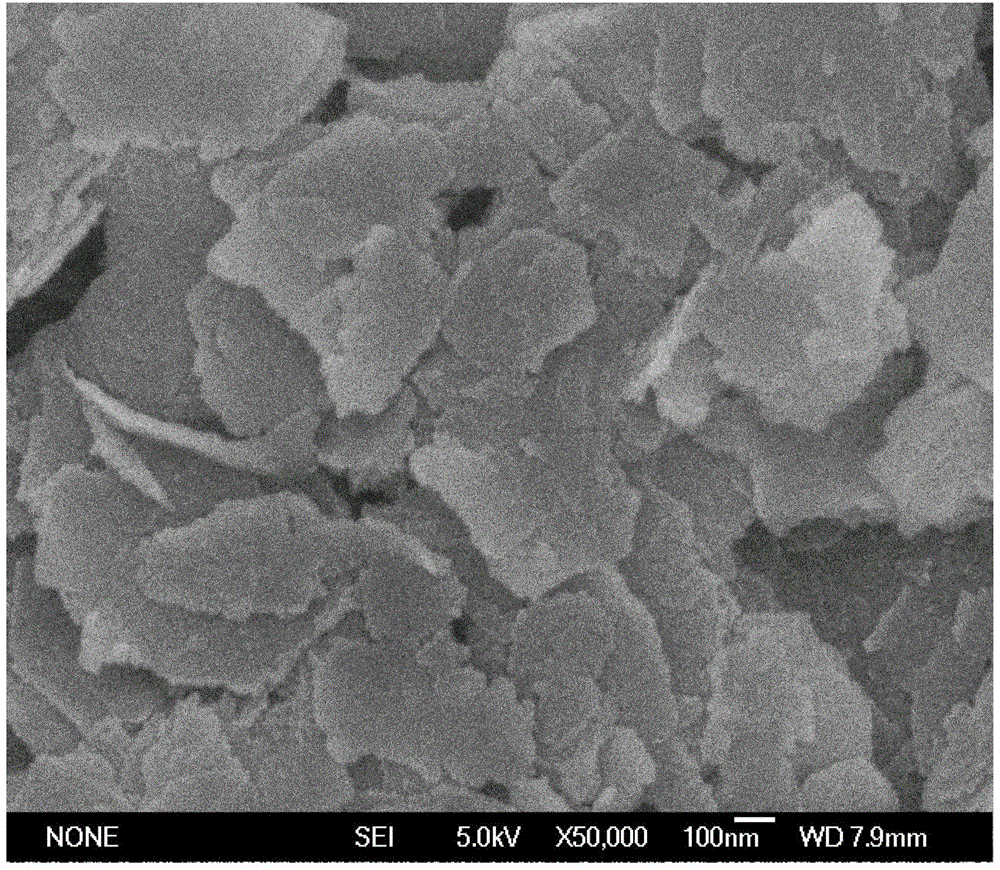

[0032] XRD detection, nitrogen adsorption-desorption isothermal detection, scanning electron microscope detection, CO 2 Programmed temperature deso...

Embodiment 2

[0034] Mg(NO 3 ) 2 ·6H 2 O dissolved in deionized water, configured as 1.5mol / L Mg 2+ aqueous solution. In addition, the configuration contains Na 2 CO 3Mixed precipitant with NaOH, where Na 2 CO 3 The concentration is 1mol / L, and the NaOH concentration is 2mol / L. 200mL 1.5mol / L Mg 2+ The aqueous solution was added dropwise to 50 mL of deionized water simultaneously with the mixed precipitant at 40°C, and the pH was controlled at 9. Stirring was continued at 40°C for 2 hours after the precipitation was completed, and then hydrothermally heated at 100°C for 20 hours. After the hydrothermal treatment, the precipitate was filtered, washed with water until neutral, and then dried at 110°C for 12 hours. After drying, it was ground and then calcined at 450°C in vacuum for 3 hours. The product was recorded as MgO-B-450, of which 450 represents the firing temperature.

Embodiment 3

[0036] Dissolve magnesium acetate in deionized water to make 0.1mol / L Mg 2+ aqueous solution. Then 0.10mol / L Na at 50°C 2 CO 3 The precipitant was gradually added dropwise to 150mL 1mol / L Mg 2+ in aqueous solution until the pH reaches 10. Stirring was continued at 50°C for 3 hours after the precipitation, and then hydrothermally aged at 160°C for 10 hours. After hydrothermal treatment, the precipitate is filtered, washed with water until neutral, and then dried at 100°C for 24 hours. After drying, it is ground and then calcined at 300°C for 3 hours in a nitrogen atmosphere. The product is marked as MgO-C-300, where 300 represents the firing temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com