Preparation method of organic amine modified layered double hydroxide/SBA-15 composite material as CO2 adsorbent and application thereof

A technology of double hydroxide and composite material, applied in the directions of alkali metal oxide/hydroxide, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high equipment corrosion rate, secondary pollution, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

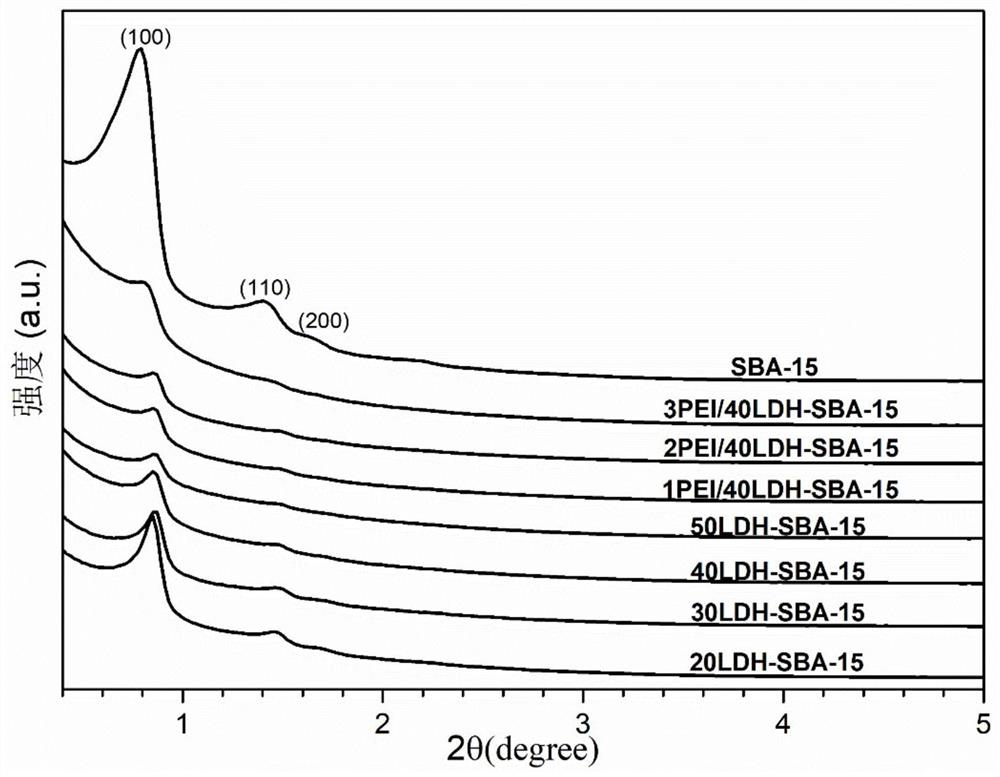

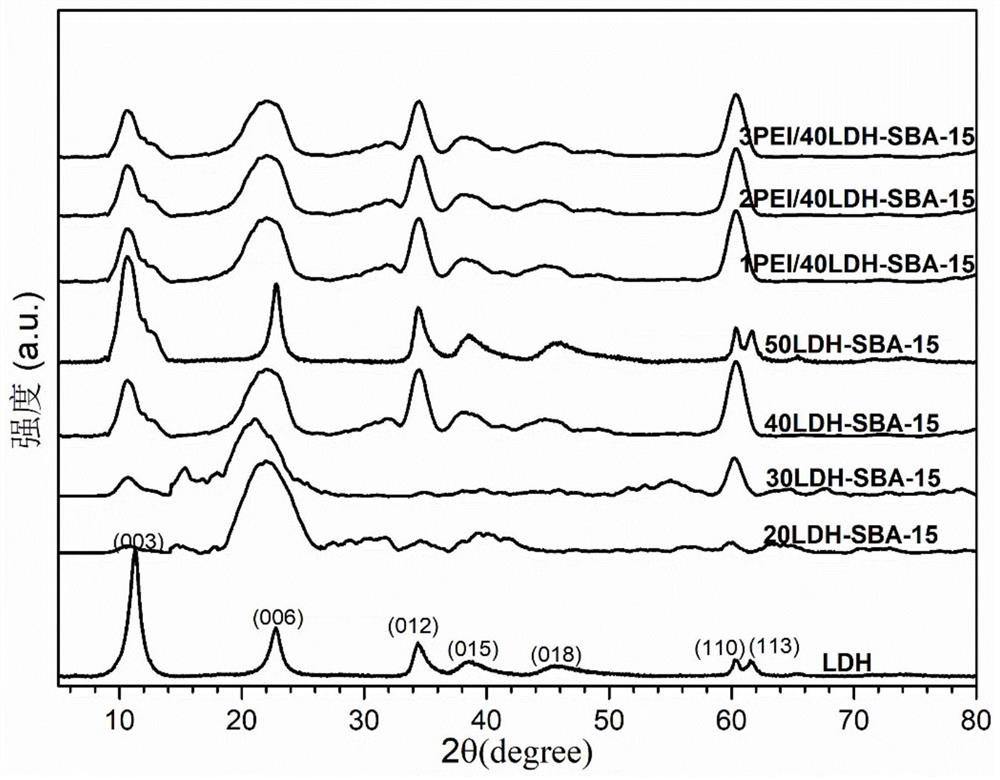

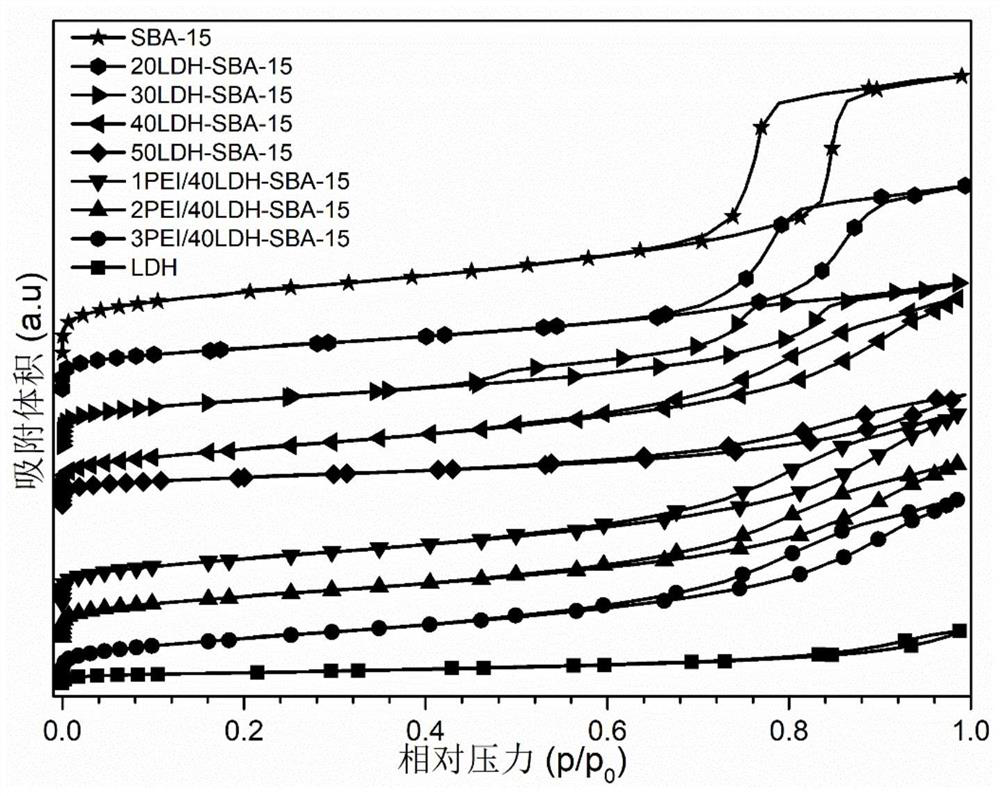

[0015] (1) Dissolve a certain amount of SBA-15 (2g) in 100ml of deionized water, and stir at room temperature for 0.5h to obtain a uniformly dispersed SBA-15 suspension. 0.036mol / L of Mg(NO 3 ) 2 ·6H 2 O and 0.012mol / L Al(NO 3 ) 3 9H 2 O is prepared in 50ml mixed liquid, added to the above suspension, and then added a certain amount of 0.6mol / L Na 2 CO 3 and 1.2mol / L NaOH mixed solution to adjust pH=10±0.1. The above mixture was stirred in a water bath at 50° C. for 8 h, then filtered and washed to pH = 7, and dried in an oven at 80° C. to obtain LDH / SBA-15. Dissolve 0.01g PEI in 2ml ethanol, then add 1g of the above LDH / SBA-15, stir the above suspension for 2h, transfer it to 60°C for vacuum drying. The obtained sample is called 1PEI / 20LDH-SBA-15, where 20 is the mass percent of LDH loading in the composite and 1 is the mass percent of PEI loading in the composite.

[0016] (2) Place the above-mentioned certain amount of adsorbent (10mg) in the thermogravimetric inst...

Embodiment 2

[0018] (1) Dissolve a certain amount of SBA-15 (1.5g) in 100ml of deionized water and stir at room temperature for 1 hour to obtain a uniformly dispersed SBA-15 suspension. 0.036mol / L of Mg(NO 3 ) 2 ·6H 2 O and 0.012mol / L Al(NO 3 ) 3 9H 2 O is prepared in 100ml mixed solution, added to the above suspension, and then added a certain amount of 1.2mol / L Na 2 CO3 and 2mol / L NaOH mixed solution to adjust pH=10±0.1. The above mixture was stirred in a water bath at 60° C. for 10 h, then filtered and washed to pH = 7, and dried in an oven at 100° C. to obtain LDH / SBA-15. 0.04g PEI was dissolved in 3ml ethanol, then 2g of the above LDH / SBA-15 was added, the above suspension was stirred for 4h, and then transferred to 60°C for vacuum drying. The obtained sample is called 2PEI / 30LDH-SBA-15, where 40 is the mass percent of LDH loading in the composite and 2 is the mass percent of PEI loading in the composite.

[0019] (2) Place the above-mentioned certain amount of adsorbent (10mg...

Embodiment 3

[0021] (1) Dissolve a certain amount of SBA-15 (1.5g) in 100ml of deionized water and stir at room temperature for 2 hours to obtain a uniformly dispersed SBA-15 suspension. 0.036mol / L of Mg(NO 3 ) 2 ·6H 2 O and 0.012mol / L Al(NO 3 ) 3 9H 2 O is prepared in 50-200ml mixed solution, added to the above suspension, and then added a certain amount of 1.5mol / L Na 2 CO 3 and 3mol / L NaOH mixed solution to adjust pH=10±0.1. The above mixture was stirred in a water bath at 60° C. for 10 h, then filtered and washed to pH = 7, and dried in an oven at 100° C. to obtain LDH / SBA-15. Dissolve 0.04g PEI in 2-10ml ethanol, then add 2g of the above LDH / SBA-15, stir the above suspension for 5h, transfer it to 60°C for vacuum drying. The obtained sample is called 2PEI / 40LDH-SBA-15, where 40 is the mass percent of LDH loading in the composite and 2 is the mass percent of PEI loading in the composite.

[0022] (2) Place the above-mentioned certain amount of adsorbent (10mg) in the thermogra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com