Preparation method of normal-temperature desulfurizing agent

A desulfurization agent, normal temperature technology, applied in the field of preparation of normal temperature desulfurization agent, can solve the problems of complex preparation process of microwave synthesis method, unfavorable industrial scale-up production, unsuitable for industrial tail gas desulfurization and purification treatment at normal temperature, and achieves easy operation and improved diffusion , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

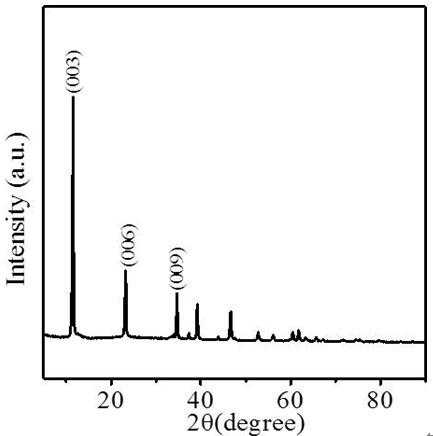

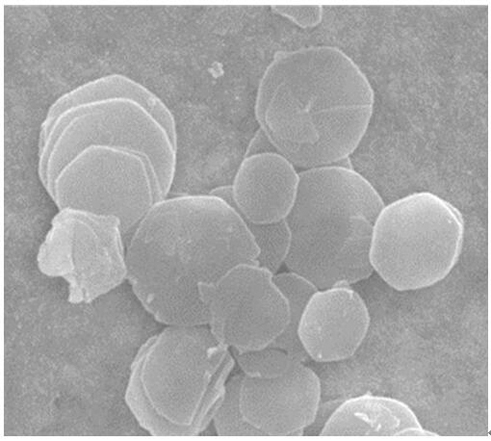

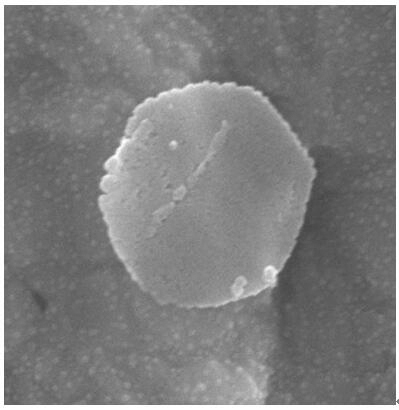

[0028] A normal temperature desulfurizer, made of NiZn 2 The Al-LDH precursor was obtained after calcination at 350 °C for 12 h, in which Ni 2+ and Zn 2+ The molar ratio is 1:2, (Ni 2+ +Zn 2+ ) and Al 3+ The molar ratio is 3:1.

[0029] The preparation method of above-mentioned a kind of normal temperature desulfurizer, its specific preparation steps are as follows:

[0030] (1) Dissolve 0.6 mmol of nickel nitrate, 1.2 mmol of zinc nitrate and 0.6 mmol of aluminum nitrate in 30 mL of deionized water to obtain Ni 2+ The concentration is 20 mmol / L, Zn 2+ The concentration is 40 mmol / L, Al 3+ Solution A with a concentration of 20 mmol / L;

[0031] (2) Dissolve 15 mmol of precipitant urea in 40 mL of deionized water to obtain solution B with a precipitant concentration of 0.375 mol / L;

[0032] (3) Mix solution A and solution B obtained in step (1) and step (2), then place the mixture of A and B in a hydrothermal kettle for reaction, and conduct a hydrothermal reaction at 1...

Embodiment 2

[0035] A normal temperature desulfurizer, made of Ni 1.5 Zn 1.5 The Al-LDH precursor was obtained after calcination at 350 °C for 12 h, in which Ni 2+ and Zn 2+ The molar ratio is 1:1, (Ni 2+ +Zn 2+ ) and Al 3+ The molar ratio is 3:1.

[0036] The preparation steps of the above-mentioned normal temperature desulfurizer refer to Example 1, the only difference is that in step (1), 0.9 mmol of nickel nitrate and 0.9 mmol of zinc nitrate, Ni 2+ and Zn 2+ The molar ratio is 1:1, and the prepared desulfurizer is denoted as room temperature desulfurizer 2.

Embodiment 3

[0038] A normal temperature desulfurizer, made of Ni 1 Zn 3 The Al-LDH precursor was obtained after calcination at 500 °C for 10 h, in which Ni 2+ and Zn 2 + The molar ratio is 1:3, (Ni 2+ +Zn 2+ ) and Al 3+ The molar ratio is 4:1.

[0039] The preparation steps of the above-mentioned normal temperature desulfurizer refer to Example 1, the only difference is that 0.45 mmol of nickel chloride, 1.35 mmol of zinc sulfate and 0.45 mmol of aluminum nitrate are used in step (1), and 20 mmol of aluminum nitrate are used in step (2). Hexamethylenetetramine, the precipitant concentration is 0.5 mol / L, the reaction temperature in step (3) is 130°C, and the desulfurizer is calcined at 500°C for 10h in step (4), the prepared desulfurizer is denoted as normal temperature desulfurizer 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com