A nitrogen-doped porous carbon-supported zns nanocomposite material and its preparation method and application

A technology of nitrogen-doped porous carbon and nanocomposite materials, applied in chemical instruments and methods, reductive alkylation preparation, physical/chemical process catalysts, etc., can solve problems that limit large-scale preparation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

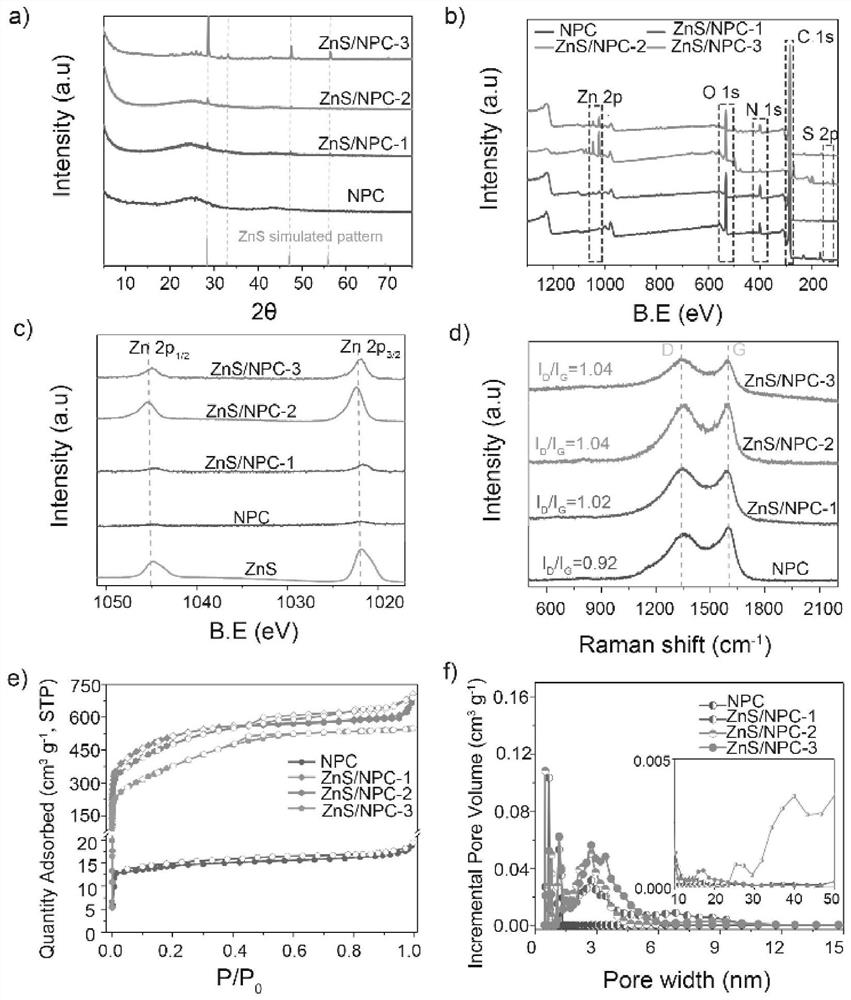

[0036] Preparation of sample NPC: BSA was dissolved in water, and after drying by freeze dryer, the obtained solid was transferred into a tube furnace and pyrolyzed under nitrogen flow. First at 10°C min -1 The heating rate of the sample is heated to 500 ° C, and then at 5 ° C min -1 The heating rate was heated to 800 °C, and kept at 800 °C for 2 h, then cooled to room temperature, and the obtained sample was named NPC.

Embodiment 2

[0038] Preparation of catalyst sample ZnS / NPC-1: ZnCl 2 and BSA dissolved in water (ZnCl 2 The mass ratio to BSA is 1.5:1), after drying by freeze dryer, the obtained solid was transferred into a tube furnace and pyrolyzed under nitrogen flow. First at 10°C min -1 The heating rate of the sample is heated to 500 ° C, and then at 5 ° C min -1 The heating rate was heated to 800 °C, and kept at 800 °C for 2 h, then cooled to room temperature, and the obtained sample was named ZnS / NPC-1.

Embodiment 3

[0040] Preparation of catalyst sample ZnS / NPC-2: ZnCl 2 and BSA dissolved in water (ZnCl 2 The mass ratio to BSA is 2.25:1), after drying by freeze dryer, the obtained solid was transferred into a tube furnace and pyrolyzed under nitrogen flow. First at 10°C min -1 The heating rate of the sample is heated to 500 ° C, and then at 5 ° C min -1 The heating rate was heated to 800°C, and kept at 800°C for 2h, then cooled to room temperature, and the obtained sample was named ZnS / NPC-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com