Barium strontium titanate ferroelectric nano single crystal particle and preparation method thereof

A nano-single crystal, barium strontium titanate technology, applied in the field of nano-materials, can solve the problems of difficult control of size and shape, unreachable ferroelectric nanocrystals, etc., and achieve the effect of easy control of the process, simple equipment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

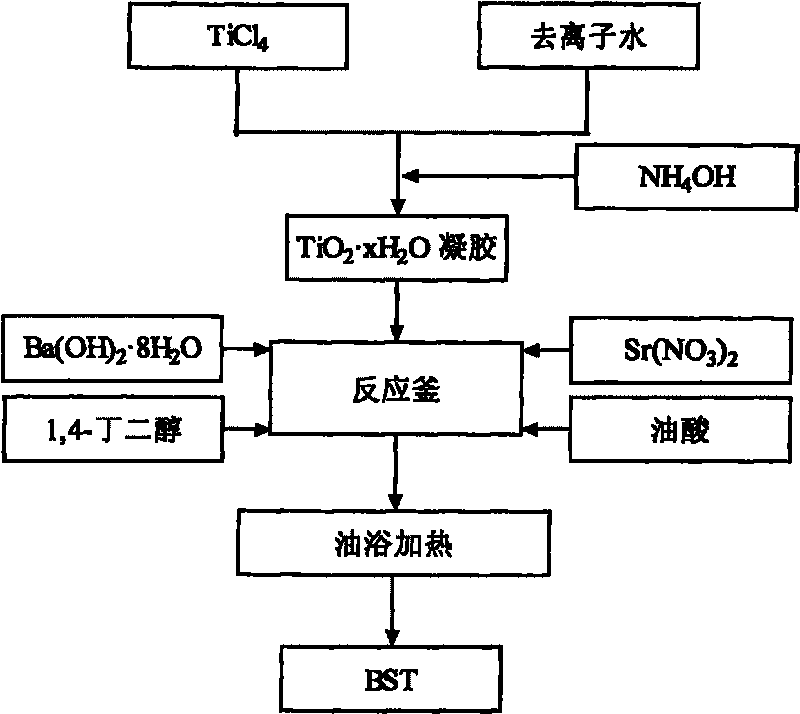

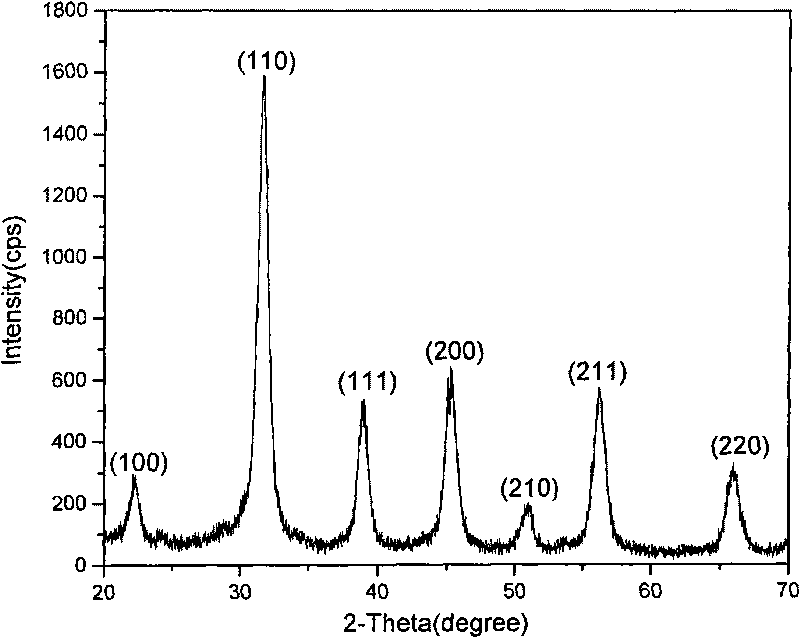

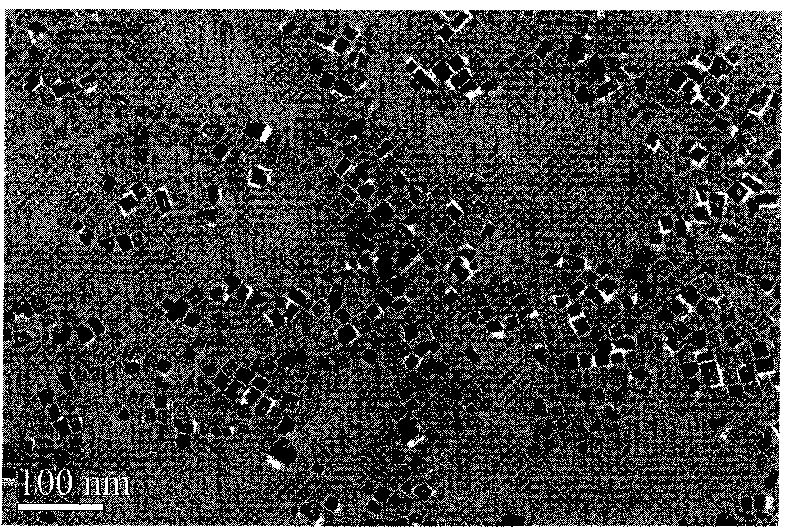

[0030] Utilize the method provided by the invention, prepare chemical composition to be Ba 0.6Sr 0.4 TiO 3 monodisperse cubic nanocrystals.

[0031] The operation steps are as follows:

[0032] 1) Under the condition of a stirring speed of 200rpm, in an ice-water bath at 1°C, in 80ml of 0°C without CO 2 Add 0.88ml 0°C TiCl dropwise in deionized water 4 , forming colorless and transparent TiOCl 2 Solution; Then dropwise add 3.3ml ammoniacal liquor (26wt%), rate of addition 0.5ml / min, form white amorphous hydrated titanium dioxide gel; Use this gel without CO 2 Wash with deionized water for 5 times, and the pH of the washing solution is 7.0; gel centrifugation is carried out at a speed of 11,000 rpm for 5 minutes;

[0033] 2) According to the stoichiometric requirement of x=0.4, in a water bath with a set temperature of 80°C and N 2 Under atmosphere protection, 2.2714gBa(OH) 2 ·8H 2 O, 1.0158gSr(NO 3 ) 2 Dissolve in 20ml of water to prepare a transparent barium-stront...

Embodiment 2

[0037] Utilize the method provided by the invention, prepare chemical composition to be Ba 0.8 Sr 0.2 TiO 3 monodisperse cubic nanocrystals.

[0038] 1) Under the condition of a stirring speed of 150rpm, in an ice-water bath at 2°C, in 80ml of 0°C without CO 2 Add 0.88ml 0°C TiCl dropwise in deionized water 4 , forming colorless and transparent TiOCl 2 Solution; Then dropwise add 3.3ml ammoniacal liquor (26wt%), rate of addition 0.3ml / min, form white amorphous hydrated titanium dioxide gel; Use this gel without CO 2 Wash with deionized water for 5 times, and the pH of the washing solution is 6.8; gel centrifugation is carried out at a speed of 10,000 rpm for 10 minutes;

[0039] 2) According to the stoichiometric requirement of x=0.2, in a water bath with a set temperature of 80°C and N 2 Under atmosphere protection, 3.0285gBa(OH) 2 ·8H 2 O, 0.5079gSr(NO 3 ) 2 Dissolve in 40ml of water to prepare a transparent barium strontium aqueous solution;

[0040] 3) Under the...

Embodiment 3

[0043] Utilize the method provided by the invention, prepare chemical composition to be BaTiO 3 monodisperse cubic nanocrystals.

[0044] 1) Under the condition of stirring speed of 250rpm, in 80ml 0℃ without CO in 4℃ ice-water bath 2 Add 0.88ml 0°C TiCl dropwise in deionized water 4 , forming colorless and transparent TiOCl 2 solution; then dropwise add 3.3ml ammoniacal liquor (26wt%), rate of addition 0.4ml / min, form white amorphous hydrated titanium dioxide gel; Use this gel without CO 2 Wash with deionized water for 5 times, and the pH of the washing solution is 7.0; gel centrifugation is carried out at a speed of 9000 rpm for 12 minutes;

[0045] 2) According to the stoichiometric requirement of x=0, under the protection of a water bath with a set temperature of 80°C and an argon atmosphere, 3.7856gBa(OH) 2 ·8H 2 O was dissolved in 50ml of water to prepare a transparent barium-strontium aqueous solution;

[0046] 3) Under the protection of nitrogen, use the ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com