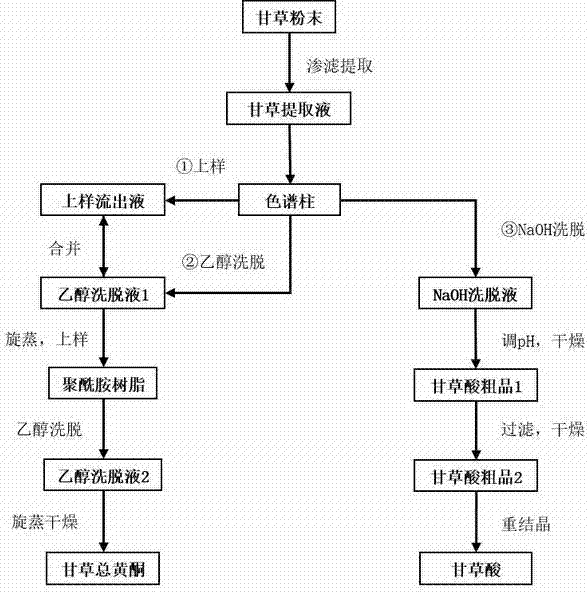

Method for simultaneously extracting and separating glycyrrhizic acid and glycyrrhiza flavonoids of glycyrrhiza based on continuous chromatography

A technology of total flavonoids of licorice and continuous chromatography is applied in the field of natural medicine extraction to achieve the effect of simplifying the extraction process, having good properties and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

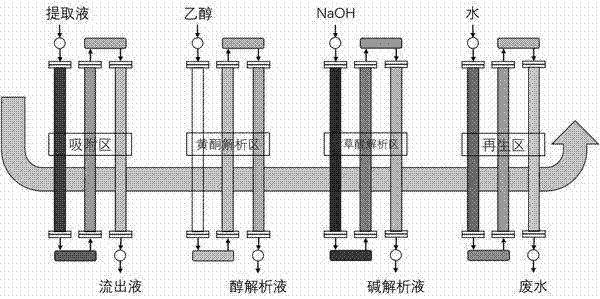

Method used

Image

Examples

Embodiment 1

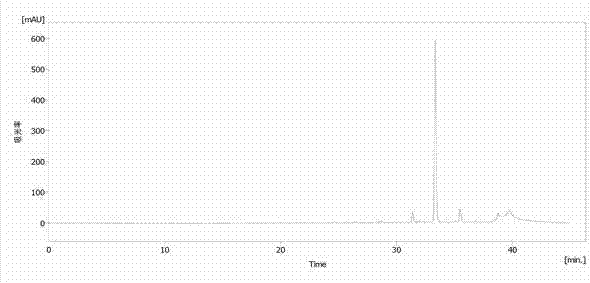

[0028] Crush the roots or stems of licorice, take 2000g of licorice powder and add 12L of ammonia alcohol solution in a beaker, stir evenly, pour it into the diafiltration device, then slowly add 68L of 0.5% ammonia water, The ammonia alcohol aqueous solution of 70% ethanol, setting inflow speed is 5ml / min, adjusts outflow speed and inflow speed to be consistent, collects leachate, obtains licorice extract. Load the licorice extract to a continuous chromatographic device equipped with D941 resin for adsorption at a flow rate of 14.08ml / min, set the single-column running time to 107min, collect the sample effluent, and use 70% ethanol solution at a flow rate of 14.00ml / min elutes a small amount of total flavonoids of licorice adsorbed on the resin, and collects the ethanol eluent 1, then uses 0.5mol / L NaOH aqueous solution to elute glycyrrhizic acid at a flow rate of 7.89ml / min, and collects the NaOH eluent. Combine the sample effluent and the ethanol eluent 1, spin the combin...

Embodiment 2

[0030] Crush the roots or stems of licorice, take 1000g of licorice powder and add 6L of ammonia alcohol solution in a beaker, stir evenly, pour it into the diafiltration device, then slowly add 34L of 0.5% ammonia water, 70 % ethanol ammonia alcohol aqueous solution, set the inflow rate to 5ml / min, adjust the outflow rate to be consistent with the inflow rate, collect the leachate, and obtain the licorice extract. Load the licorice extract to a continuous chromatographic device equipped with D941 resin for adsorption at a flow rate of 14.08ml / min, set the single-column running time to 107min, collect the sample effluent, and use 70% ethanol solution at a flow rate of 14.00ml / min elutes a small amount of total flavonoids of licorice adsorbed on the resin, and collects the ethanol eluent 1, then uses 0.5mol / L NaOH aqueous solution to elute glycyrrhizic acid at a flow rate of 7.89ml / min, and collects the NaOH eluent. Combine the sample effluent and the ethanol eluent 1, spin th...

Embodiment 3

[0032]Crush the roots or stems of licorice, take 4000g of licorice powder and add 24L of ammonia alcohol solution in a beaker, stir evenly, pour it into the diafiltration device, then slowly add 136L of 0.5% ammonia water, 70 % ethanol ammonia alcohol aqueous solution, set the inflow rate to 5ml / min, adjust the outflow rate to be consistent with the inflow rate, collect the leachate, and obtain the licorice extract. Load the licorice extract to a continuous chromatographic device equipped with D941 resin for adsorption at a flow rate of 14.08ml / min, set the single-column running time to 107min, collect the sample effluent, and use 70% ethanol solution at a flow rate of 14.00ml / min elutes a small amount of total flavonoids of licorice adsorbed on the resin, and collects the ethanol eluent 1, then uses 0.5mol / L NaOH aqueous solution to elute glycyrrhizic acid at a flow rate of 7.89ml / min, and collects the NaOH eluent. Combine the sample effluent and the ethanol eluent 1, spin t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com