Nano porous fiber filter tip additive material for reducing amount of released formonitrile in cigarette smoke, preparation method and application

A technology of fiber materials and additive materials, which is applied in applications, e-liquid filter elements, fiber treatment, etc., can solve the problems of large loss of cigarette aroma, high catalytic temperature, and unfavorable operation, etc., to increase specific surface area and improve adsorption efficiency , The effect of simple preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

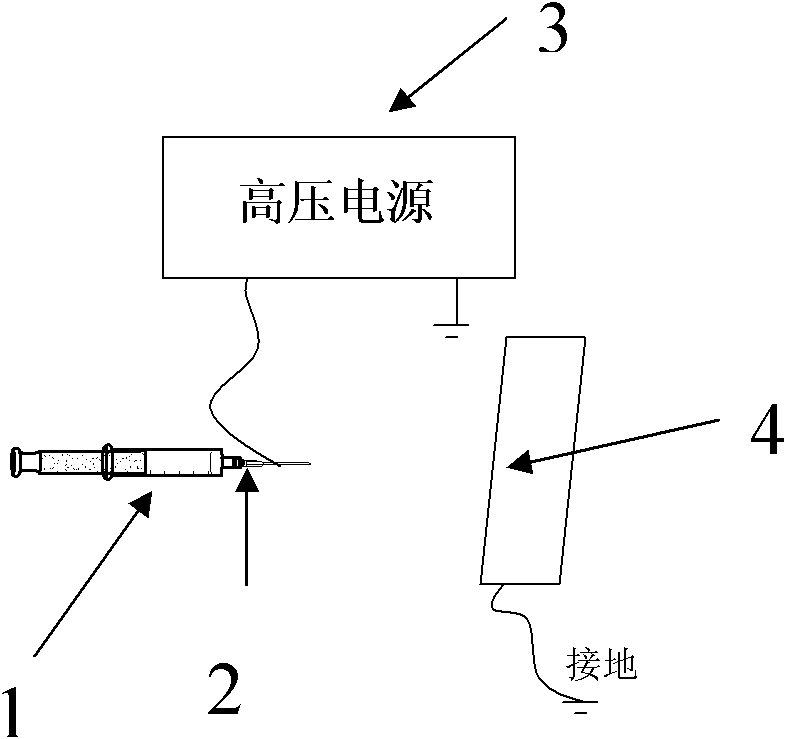

[0030] The specific steps of the preparation method of the present invention are as follows:

[0031] 1. Add 0.8-2.0 g of tetraisopropyl titanate precursor to 2.0-4.0 mL of absolute ethanol, and add an equal volume of acetic acid, and stir magnetically under dry conditions to mix evenly. The preferred quality of tetraisopropyl titanate is 1.5g, and the volume of absolute ethanol and acetic acid is 3mL;

[0032] 2. Add 0.30 to 0.60 g of polyvinylpyrrolidone (PVP) solution to 2.0 to 4.0 mL of ethanol, preferably with a mass of 0.45 g of polyvinyl pyrrolidone and a volume of 3 mL of ethanol, and stir under dry conditions to obtain a homogeneous solution. The obtained polymer homogeneous solution is quickly added to the titanium dioxide precursor solution prepared in step (1), stirred under dry conditions for 30-90 minutes, and the optimal stirring time is 60 minutes;

[0033] 3. Add the solution prepared in the above step (2) into the syringe, control the voltage between the wor...

Embodiment 1

[0037] Material preparation:

[0038] 1.1.5g tetraisopropyl titanate, 3mL ethanol and 3mL acetic acid were magnetically stirred for 10min;

[0039] 2. Add PVP solution (0.45g PVP dissolved in 3mL ethanol) to the above homogeneous solution, and continue to stir for 1h.

[0040] 3. Add the above precursor solution into the syringe, control the voltage between the working receiving electrode and the needle to 10KV, adjust the distance between the receiver and the spinning needle to 10cm, and the outflow rate of the solution to 0.5mL / h.

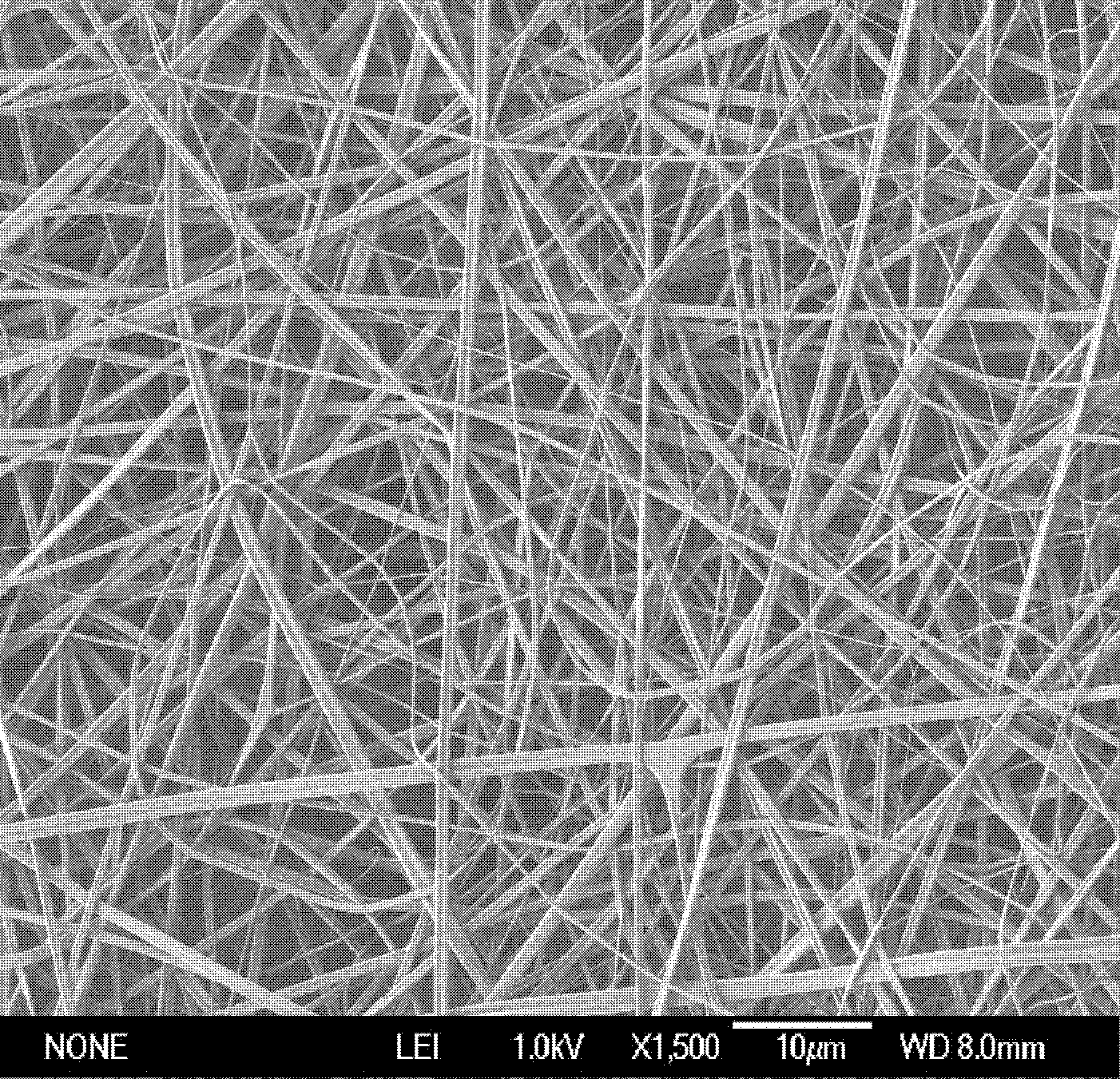

[0041] 4. The prepared titanium dioxide fibers were placed in a muffle furnace for calcination at 450° C. for 3 hours, and an electrospun titanium dioxide nanoporous fiber material was obtained after calcination. The specific surface of the nanofiber obtained at last is characterized by nitrogen adsorption (Sorptomatic1990 full-automatic physical and chemical adsorption instrument), and its specific surface area is 98m 2 / g, its shape, length an...

Embodiment 2

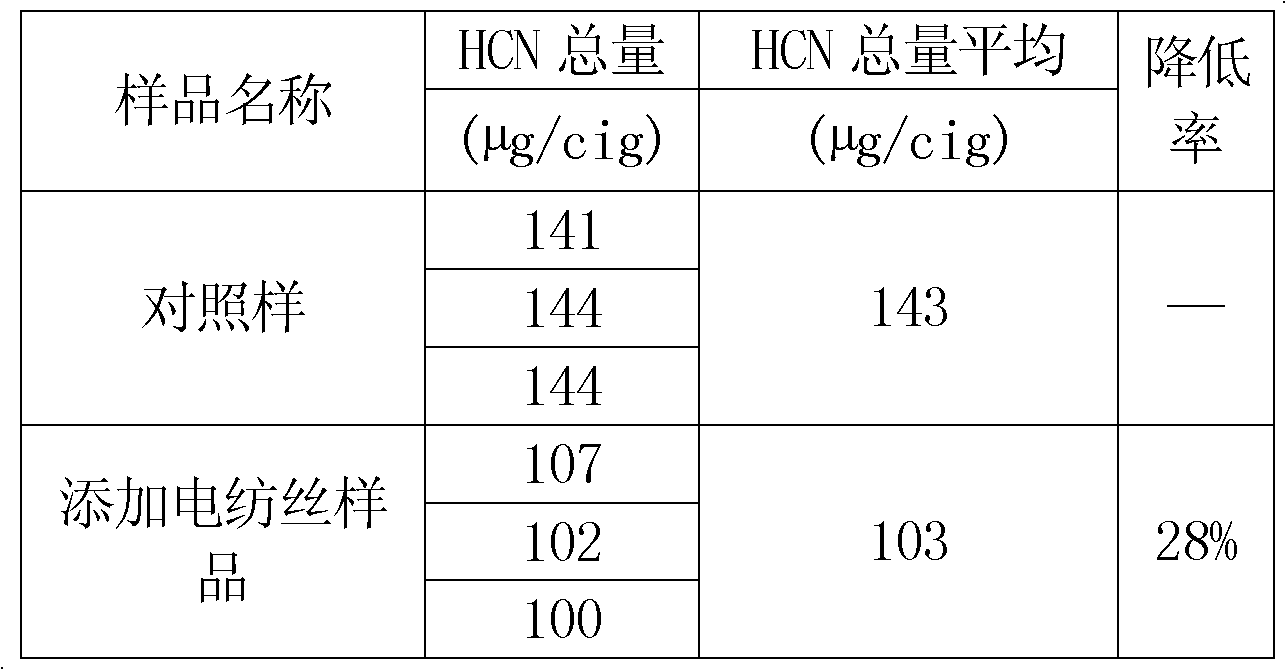

[0047] Example 2: The material preparation method is the same as in Example 1. The electrospun titanium dioxide nanoporous fiber material is used as a composite filter additive material, and the addition amount is 30 mg / cig. The cigarette without any filter adsorption material is used as a control sample. The cigarette smoking test was carried out on the smoking machine according to the standard smoking conditions, and the release of hydrocyanic acid was detected according to the standard YCT253-2008. Each sample has three parallel samples, and the results are shown in Table 2.

[0048] Table 2 The addition amount of electrospun titanium dioxide nanomaterials is 30mg / cig

[0049]

[0050] The above results show that the material of the present invention can be used in the production of composite filter cigarettes, can reduce the release of hydrocyanic acid in mainstream cigarette smoke by more than 40%, and does not affect the smoking quality of cigarettes. The material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com