A kind of aniline hydrogenation catalyst, preparation method and application

A hydrogenation catalyst and a catalyst technology, which are applied in the directions of catalyst carrier, amino compound preparation, chemical instruments and methods, etc., can solve the problems of low catalyst activity, high content of dicyclohexylamine, equipment corrosion, etc., and achieve the inhibition of by-product bicyclic The formation of hexylamine, the effect of improving hydrogenation activity and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

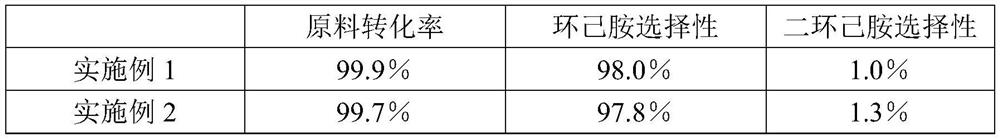

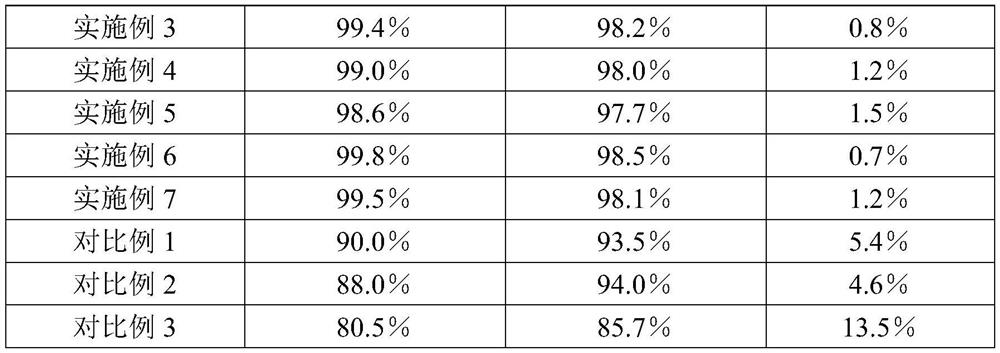

Examples

Embodiment 1

[0045] (1) Preparation of carrier:

[0046] 76.9g Mg(NO 3 ) 2 ·6H 2 O, 37.5g Al (NO 3 ) 3 ·9H 2 O and 240 g of urea were dissolved in 400 mL of deionized water to obtain a transparent solution; the solution was transferred to an autoclave and crystallized at 110 °C for 12 h to obtain a solid-liquid mixture. The solid was obtained by filtration, washed with deionized water, and dried to obtain a Mg / Al-based hydrotalcite precursor. The Mg / Al hydrotalcite precursor was calcined at 550 °C for 6 h to obtain a Mg / Al bimetallic oxide support.

[0047] (2) prepare catalyst intermediate:

[0048] 74.1g Co(NO 3 ) 2 ·6H 2 O and 4.6g Ce (NO 3 ) 3 ·6H 2 O was dissolved in deionized water, 50 g of carrier powder was added to the above aqueous solution, stirred evenly, sonicated for 0.5 h, then left to stand at room temperature for 12 h; finally, dried at 100 °C for 18 h and calcined at 450 °C for 6 h to obtain catalyst intermediate;

[0049] (3) Preparation of catalyst:

[005...

Embodiment 2

[0052] (1) Preparation of carrier:

[0053] 73.8g MgSO 4 ·7H 2 O, 25.6g Al 2 (SO 4 ) 3 and 324 g of urea were dissolved in 450 mL of deionized water to obtain a transparent solution; the solution was transferred to an autoclave and crystallized at 100 ° C for 20 h to obtain a solid-liquid mixture. The solid was obtained by filtration, washed with deionized water, and dried to obtain a Mg / Al-based hydrotalcite precursor. The Mg / Al hydrotalcite precursor was calcined at 500 °C for 8 h to obtain a Mg / Al bimetallic oxide support.

[0054] (2) prepare catalyst intermediate:

[0055] Dissolve 105.7 g of cobalt acetylacetonate and 13.0 g of vanadyl acetylacetonate in ethanol, add 50 g of carrier powder to the above solution, stir evenly, sonicate for 1 hour, and then stand at room temperature for 18 hours; finally at 110 ° C Dry for 12h, calcinate at 500℃ for 5h to obtain the catalyst intermediate;

[0056] (3) Preparation of catalyst:

[0057] In an argon-filled glove box, ...

Embodiment 3

[0059] (1) Preparation of carrier:

[0060] Dissolve 81.3 g of magnesium chloride hexahydrate, 24.1 g of aluminum chloride hexahydrate and 450 g of urea in 500 mL of deionized water to obtain a transparent solution; transfer the solution to an autoclave and crystallize at 120 ° C for 10 h to obtain a solid-liquid mixture. The solid was obtained by filtration, washed with deionized water, and dried to obtain a Mg / Al-based hydrotalcite precursor. The Mg / Al hydrotalcite precursor was calcined at 520 °C for 7 h to obtain a Mg / Al bimetallic oxide support.

[0061] (2) prepare catalyst intermediate:

[0062] Dissolve 80.8g of cobalt chloride hexahydrate and 7.2g of manganese chloride tetrahydrate in deionized water, add 50g of carrier powder to the above solution, stir evenly, sonicate for 0.5h, and then let stand for 15h at room temperature; Finally, it was dried at 120°C for 12h and calcined at 400°C for 10h to obtain the catalyst intermediate;

[0063] (3) Preparation of catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com