Pure-phase zirconium-based desulfurization catalyst, and preparation method and application thereof

A desulfurization catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of influence, prone to side reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

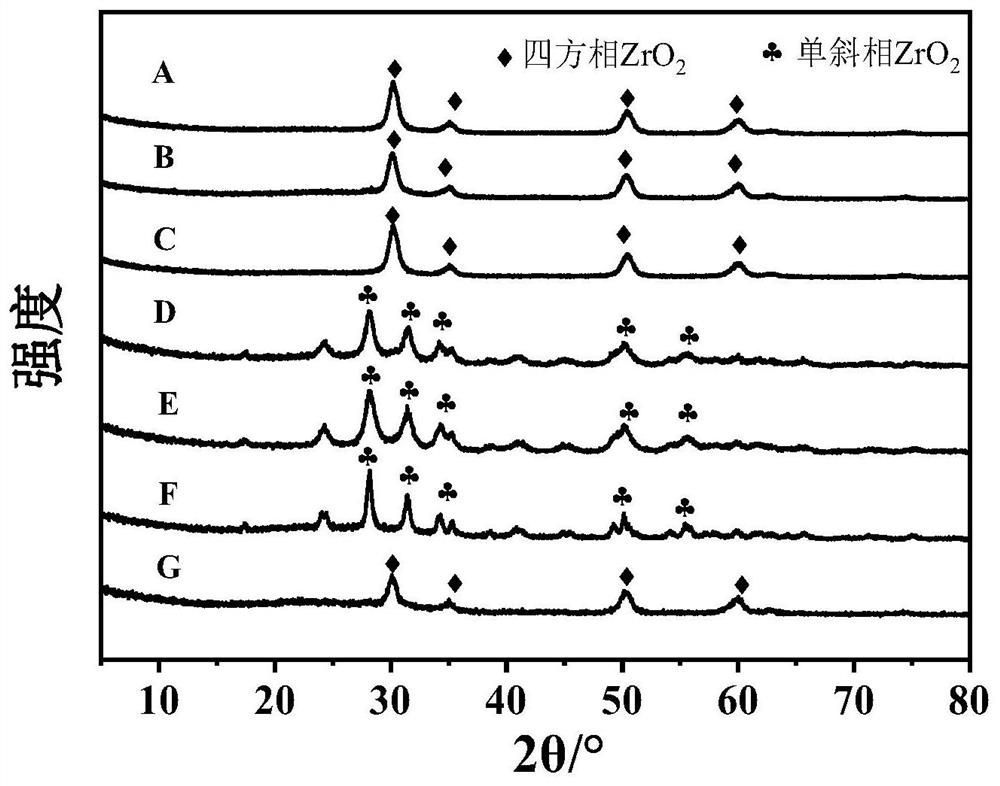

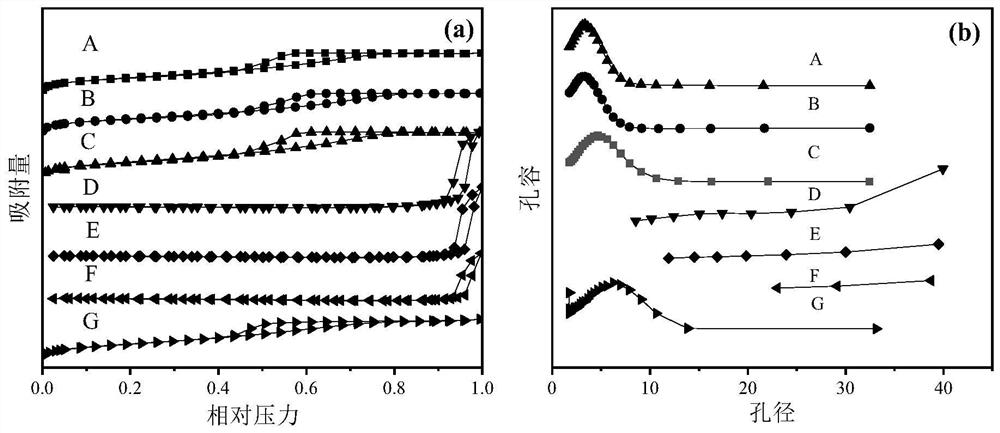

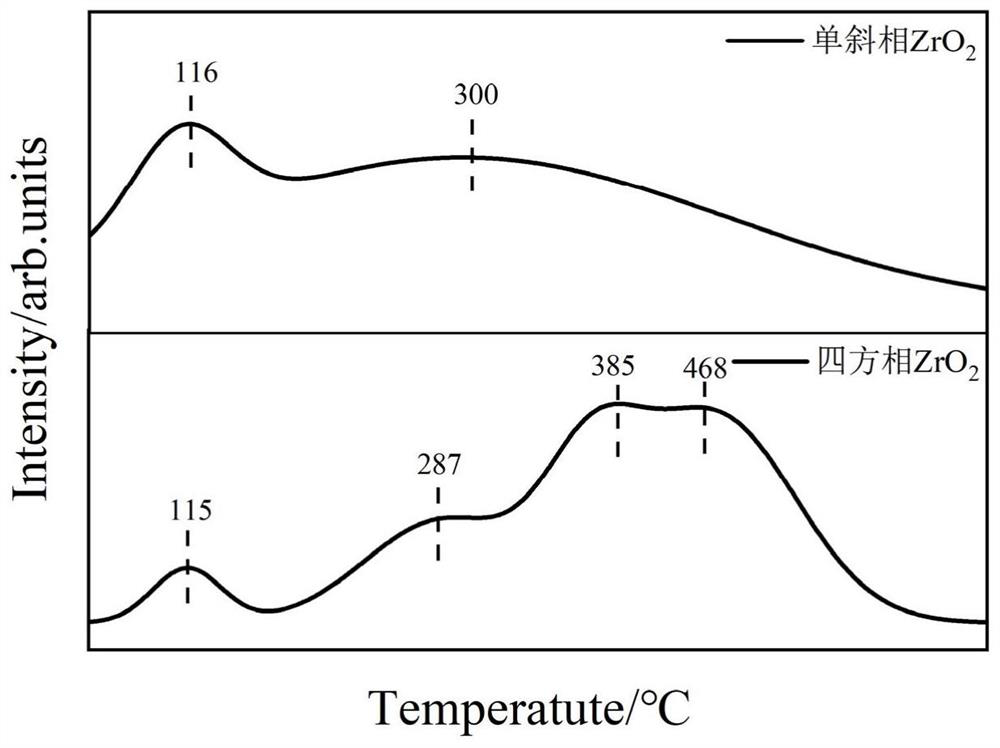

[0029] A pure-phase zirconium-based desulfurization catalyst, the pure-phase zirconium-based desulfurization catalyst is regular nanoparticles of pure tetragonal phase.

[0030] The preparation method of the above-mentioned pure-phase zirconium-based desulfurization catalyst specifically comprises the following steps:

[0031] (1) Glycerin and zirconium oxychloride are mixed and dissolved in 50mL deionized water according to the molar ratio of 2:1, after adding polyvinylpyrrolidone, fully stirred until completely dissolved to obtain a mixed solution, wherein polyvinylpyrrolidone is used as the surface Active agent, the mass ratio of addition amount and zirconium salt is 3:1;

[0032] (2) Sodium hydroxide is dissolved in deionized water, and it is configured into a sodium hydroxide solution with a concentration of 0.1M;

[0033] (3) Slowly add the sodium hydroxide solution dropwise to the mixed solution A, adjust the pH of the mixed solution to be 8, place the mixed solution i...

Embodiment 2

[0036] A pure-phase zirconium-based desulfurization catalyst, the pure-phase zirconium-based desulfurization catalyst is regular nanoparticles of pure tetragonal phase.

[0037] The preparation method of the above-mentioned pure-phase zirconium-based desulfurization catalyst specifically comprises the following steps:

[0038](1) Ethylene glycol and zirconium nitrate are mixed and dissolved in 50mL deionized water according to the molar ratio of 5:1, after adding cetyltrimethylammonium bromide, fully stirred until completely dissolved to obtain a mixed solution, wherein, Hexadecyltrimethylammonium bromide is used as surfactant, and the mass ratio of addition amount and zirconium salt is 1:1;

[0039] (2) Potassium hydroxide is dissolved in deionized water to be configured as a potassium hydroxide solution with a concentration of 0.5M;

[0040] (3) Potassium hydroxide solution is slowly added dropwise to the mixed solution A, the pH of the mixed solution is adjusted to be 12, ...

Embodiment 3

[0043] A pure-phase zirconium-based desulfurization catalyst, the pure-phase zirconium-based desulfurization catalyst is regular nanoparticles of pure tetragonal phase.

[0044] The preparation method of the above-mentioned pure-phase zirconium-based desulfurization catalyst specifically comprises the following steps:

[0045] (1) Mix and dissolve isopropanol and zirconium oxynitrate in 50mL deionized water according to the molar ratio of 4:1, add ammonium bicarbonate, and stir until completely dissolved to obtain a mixed solution, wherein ammonium bicarbonate is used as the surface Active agent, the mass ratio of addition amount and zirconium salt is 2:1;

[0046] (2) Lithium hydroxide is dissolved in deionized water to be configured as a lithium hydroxide solution with a concentration of 0.3M;

[0047] (3) Lithium hydroxide solution is slowly added dropwise to the mixed solution, and the pH of the mixed solution is adjusted to be 10. The mixed solution is placed in a hydrot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com