Flotation method of sulphide gold containing ores

A technology for sulfide ores, applied in flotation, solid separation, etc., can solve the problems of long flotation time, low gold recovery rate, large collector consumption, etc. The effect of low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

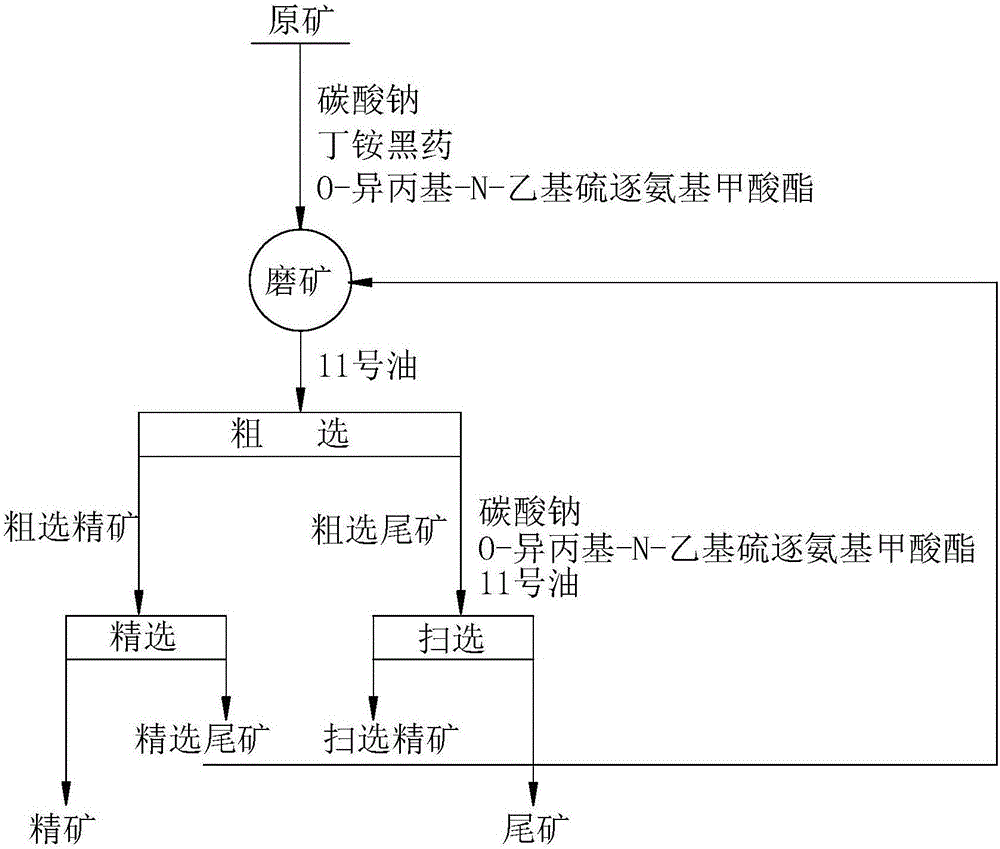

Embodiment 1

[0018] The main recoverable element in the ore of a gold mine in Liaoning is gold, the grade of raw gold is 1.8g / t, and the main sulfide minerals are pyrite and arsenopyrite. It adopts one roughing, one sweeping, one concentrate, concentrated tailings and sweeping concentrate to return to the grinding process for flotation, and the grinding fineness is -0.074mm, which accounts for 93%. Sodium carbonate 1000g / t, collector: butylammonium black drug 40g / t, O-isopropyl-N-ethylthiocarbamate 40g / t, roughing concentration 33%, foaming agent No. 11 oil The dosage is 25g / t, stirred for 0.8min, and the flotation time is 3.5min. Add 300g / t of sodium carbonate to the sweeping operation, stir for 3min, add 30g / t of O-isopropyl-N-ethylthiocarbamate and The foaming agent No. 11 oil is 10g / t, the stirring and flotation time are both 3min, and the selection flotation time is 2min, and the gold content grade of the concentrate is 28g / t and the gold recovery rate is 93%. The flotation test was ...

Embodiment 2

[0020] The main recoverable element in the ore of a gold mine in Henan is gold, the grade of raw gold is 1.5g / t, and the main sulfide minerals are pyrite and pyrrhotite. It adopts one roughing, one sweeping, one concentrate, concentrated tailings and sweeping concentrate to return to the grinding process for flotation. When the grinding fineness is -0.074mm, it accounts for 90%. Sodium carbonate 1100g / t, collector: butylammonium black drug 45g / t, O-isopropyl-N-ethylthiocarbamate 50g / t, roughing concentration 33%, foaming agent No. 11 oil Dosage is 30g / t, stirring for 0.5-1min, flotation time is 3-4min, adding 350g / t of sodium carbonate for sweeping operation, stirring for 3min, adding O-isopropyl-N-ethylthiocarbamate 35g / t and foaming agent No. 11 oil 10g / t, the stirring and flotation time are both 3min, and the selection flotation time is 2min, the test index of gold content of 42g / t and gold recovery rate of 90% is obtained. . The flotation test was carried out according ...

Embodiment 3

[0022] The main recoverable element in the ore of a gold mine in Hebei is gold, the grade of raw gold is 2.0g / t, and the main sulfide minerals are chalcopyrite and pyrite. It adopts one roughing, one sweeping, one concentrate, concentrated tailings and sweeping concentrate to return to the grinding process for flotation. The grinding fineness is -0.074mm, which accounts for 95%. Sodium carbonate 1200g / t, collector: butyl ammonium black drug 50g / t, O-isopropyl-N-ethylthiocarbamate 50g / t, roughing concentration 33%, foaming agent No. 11 oil The dosage is 30g / t, stirring for 0.5-1min, flotation time is 3-4min, adding 400g / t of sodium carbonate for sweeping operation, stirring for 3min, adding O-isopropyl-N-ethylthiocarbamate 35g / t and foaming agent No. 11 oil 15g / t, the stirring and flotation time are both 3min, and the selection flotation time is 2min, the gold content grade of the concentrate is 38g / t and the gold recovery rate is 94%. . The flotation test was carried out ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com