Method for applying bacillus amyloliquefaciens to soy sauce brewage

A technology for dissolving amyloid spores and bacilli, used in food ingredients as taste improvers, food ingredients as odor improvers, food science and other directions, can solve problems such as increasing flavor, reduce urethane, improve flavor substances and taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

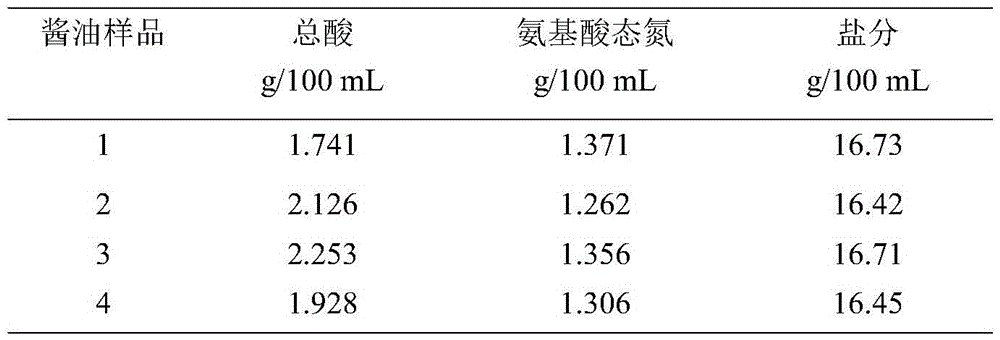

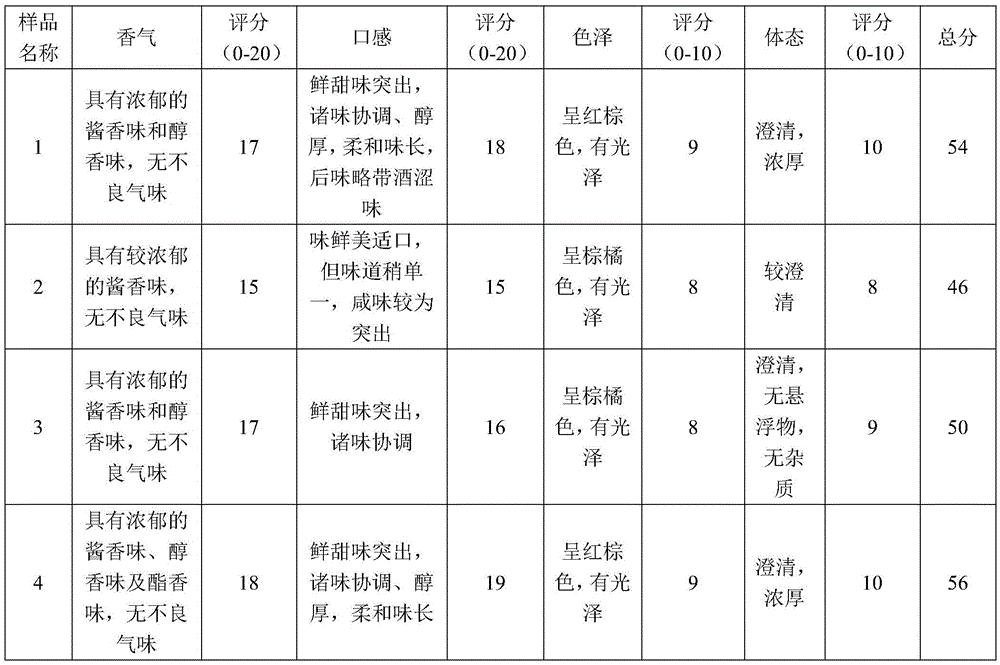

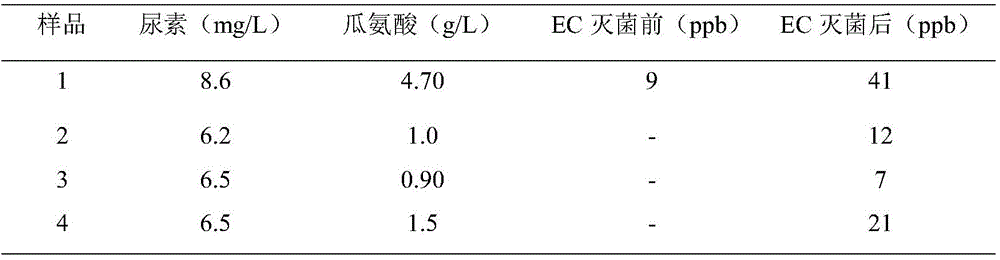

[0020] Example 1: Soy sauce production

[0021] (1) Koji making: Soak defatted soybeans and fried wheat for 8 hours, sterilize at 121 °C for 5 minutes, cool to 80 °C, add bran and flour in proportion, and the mass ratio of defatted soybeans, fried wheat, bran, and flour is 20:15 :1:1, simultaneously inoculated with Aspergillus oryzae spores, the inoculum size was 8×10 9 pcs / g of initial raw material, cultivate in a 30°C incubator, turn the koji once every 6-8h, cultivate for 46-48h, the koji turns into a bright green, and the koji-making is completed;

[0022] (2) Fermentation: The koji and 20% brine (w:v) were mixed and fermented at a volume ratio of 1:1.7, and the 3rd day was inoculated with Bacillus amyloliquefaciens BBE-JY06, the temperature was controlled at 10-20°C, and the 7th day of fermentation The final concentration of inoculation is 10 7 CFU / mL of yeast Lloyd's, and then inoculated on the 14th day of fermentation to a final concentration of 10 in fermented grains...

Embodiment 2

[0040] Embodiment 2: the application of Bacillus amyloliquefaciens BBE-JY06 in increasing the content of gamma-polyglutamic acid in soy sauce

[0041] (1) BBE-JY06 utilizes L-glutamic acid to produce γ-polyglutamic acid in pure medium

[0042] Seed medium: sucrose 1%, peptone 1%, L-glutamic acid 2%, MgSO 4 0.1%, NaCl0.5%, K 2 HPO 4 0.05%, pH7.0, sterilized at 115°C for 20min.

[0043] Fermentation medium: sucrose 2%, peptone 2%, L-glutamic acid 2%, MgSO 4 0.1%, NaCl2%, K 2 HPO 4 0.05%, pH7.0, sterilized at 115°C for 20min.

[0044] Pick a small amount of Bacillus amyloliquefaciens BBE-JY06 into the seed medium, and culture it on a shaker at 200 rpm at 37°C for 12 hours. Bacillus amyloliquefaciens was inoculated into a 250 mL shake flask filled with 50 mL of fermentation medium at an inoculum amount of 10%, and cultured statically at 37° C. for 24 h.

[0045] (2) BBE-JY06 utilizes L-glutamic acid to produce γ-polyglutamic acid in soy sauce fermentation, and the specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com