Fine purification system and method for carbonization crude benzol

A technology for coking crude benzene and a refining method, which is applied to a refining system for coking crude benzene and its refining field, can solve the problems of large equipment investment, large consumption of heat energy and circulating cooling water, increased investment, etc., so as to reduce investment and production costs, The effect of improving production efficiency and simplifying process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

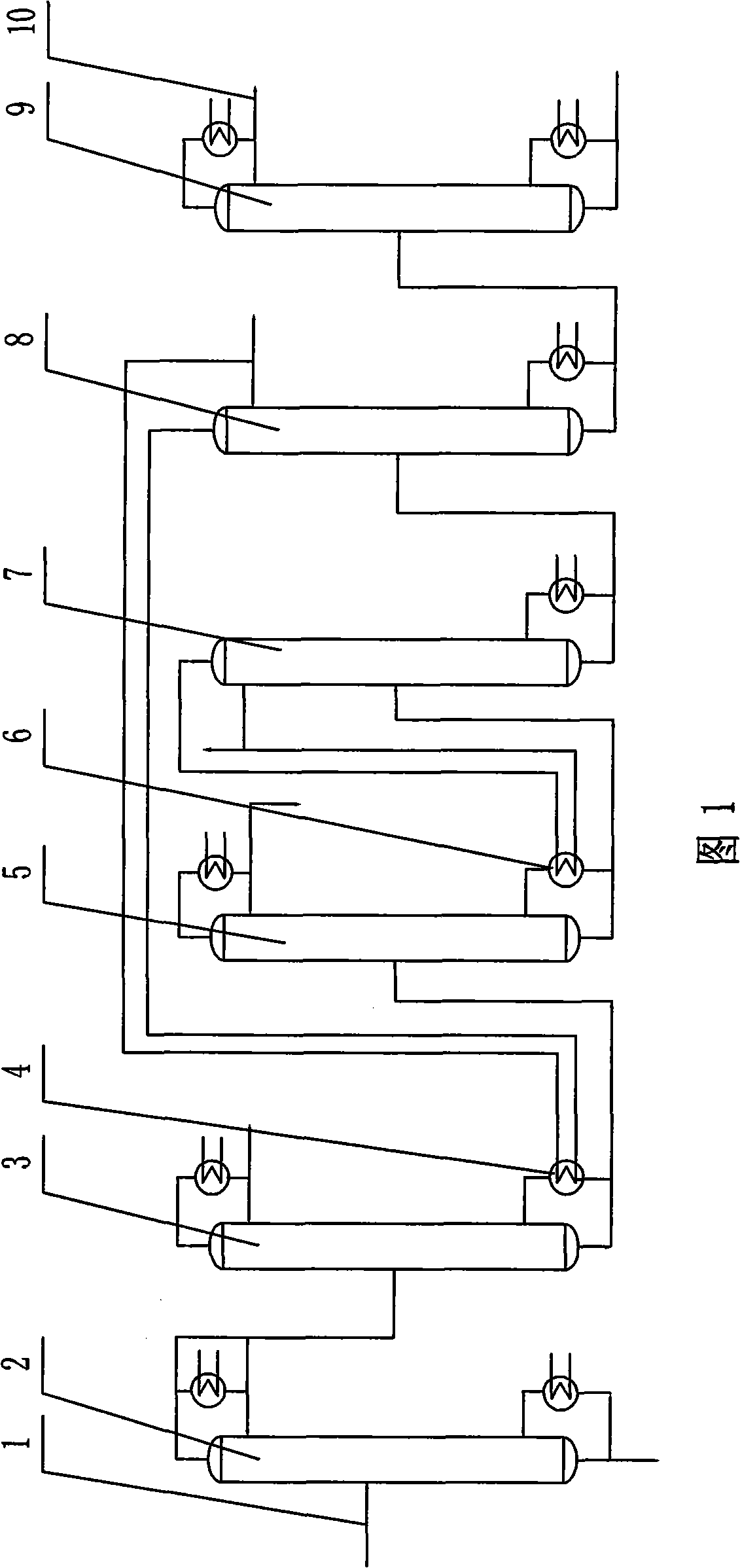

Image

Examples

Embodiment 1

[0027] (1). Coking crude benzene with a benzene content of 73% is used as a raw material. The raw material of coking crude benzene first enters the two-benzene tower, and the raw material is divided into hydrogen sulfide, carbon disulfide, cyclopentadiene, and methylcyclohexyl through the two-benzene tower. Light components including alkanes, benzene, toluene, xylene, etc. and heavy components with a boiling point higher than xylene, the overhead components enter the initial distillation tower, and the two-benzene tower operates under normal pressure, and the operating temperature at the top of the tower is 90°C; the initial distillation tower removes the light components in the raw material, including hydrogen sulfide, carbon disulfide, cyclopentadiene and part of methylcyclohexane, etc. The initial distillation tower operates under normal pressure, and the tower top temperature The temperature is 52°C, and the bottom component enters the pure benzene first tower of the pure b...

Embodiment 2

[0031] (1). Coking crude benzene with a benzene content of 73% is used as a raw material. The raw material of coking crude benzene first enters the two-benzene tower, and the raw material is divided into hydrogen sulfide, carbon disulfide, cyclopentadiene, and methylcyclohexyl through the two-benzene tower. Light components including alkanes, benzene, toluene, xylene, etc. and heavy components with a boiling point higher than xylene, the distillate components from the top of the tower enter the initial distillation tower, and the two benzene towers are operated under reduced pressure, and the operating temperature at the top of the tower is 66°C; the initial distillation tower removes the light components in the raw material, including hydrogen sulfide, carbon disulfide, cyclopentadiene and part of methylcyclohexane, etc. The initial distillation tower operates under a slight negative pressure, and the top The temperature is 48°C, and the bottom component enters the pure benzen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com