Method for refining carbonization crude benzole

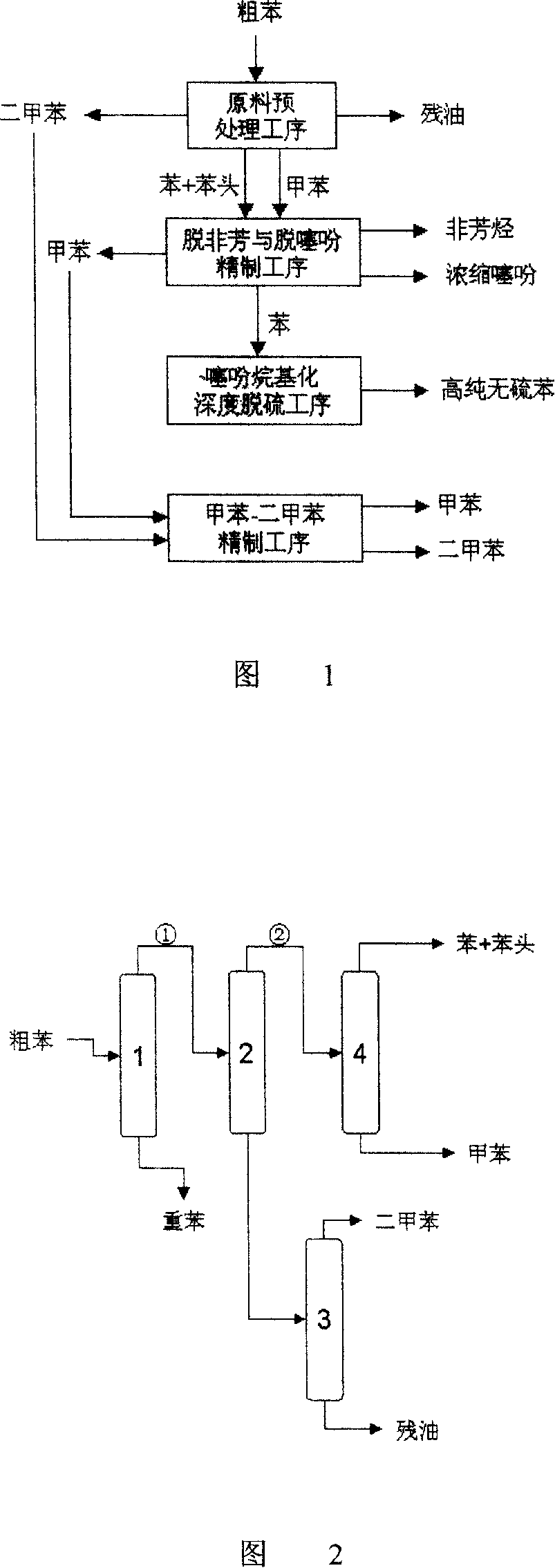

A technology for coking crude benzene and a refining method, which is applied in distillation purification/separation and other directions, can solve the problems that thiophene cannot be completely removed, affect product purity, and the purification depth is not enough, so as to achieve low operating costs, avoid sulfonation losses, and save energy. The effect of investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

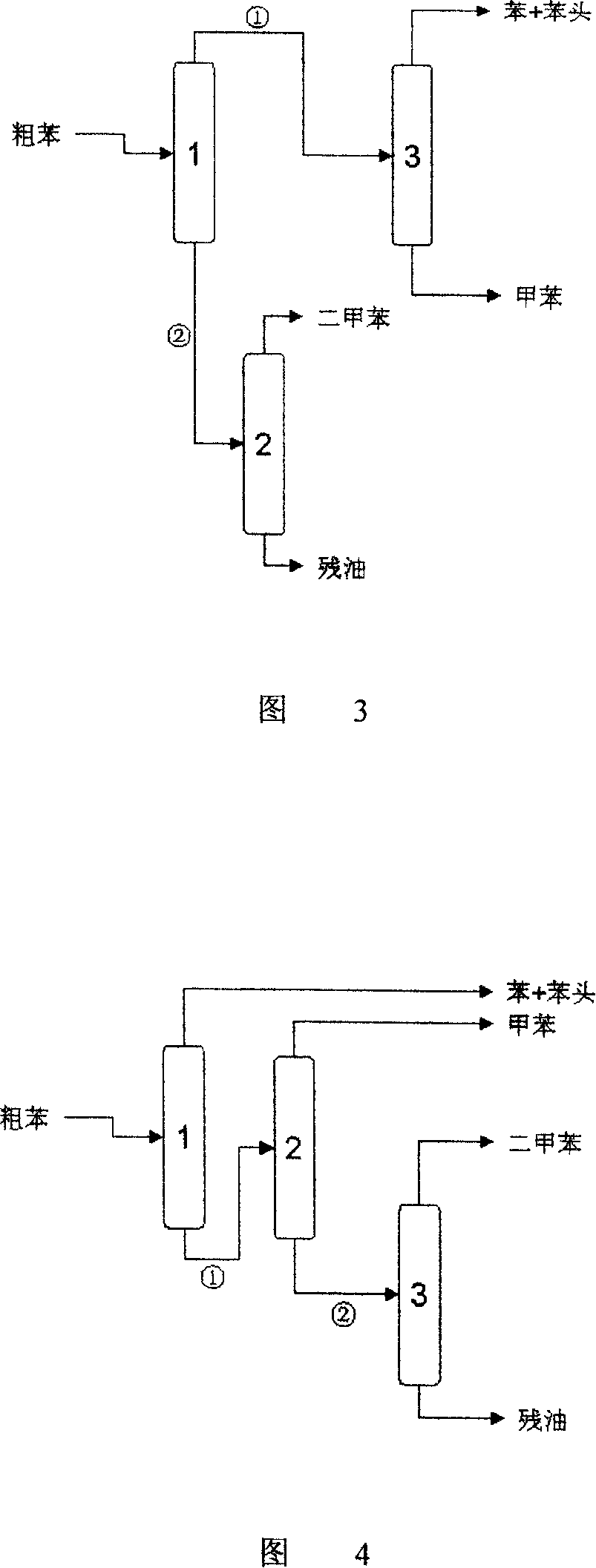

[0047] Taking the coking crude benzene produced by the coking enterprise as the raw material (wherein the mass contents of benzene and toluene are 68.8% and 12.1%, respectively), after dehydration, filtering solid impurities, and preheating it, according to the crude benzene separation scheme A, from the two benzene The middle feed of column 1, the column is operated at atmospheric pressure and semi-continuously, and the crude benzene is divided into light benzene fractions below 150°C (wherein the concentration of thiophene is 3350 mg / L) and heavy benzene fractions above 150°C; The toluene front fraction (containing toluene fraction) is distilled from the top of the tower through the cutting tower 2, and the bottom fraction is rectified and separated by the xylene tower 3 to obtain the xylene fraction. The toluene front distillate obtained from the top of the cutting tower 2 is then passed through the benzene-toluene cutting tower to realize the separation of the benzene front...

Embodiment 2

[0054] The coking crude benzene produced by the coking enterprise is used as the raw material (wherein the mass content of benzene and toluene is 68.8% and 12.1% respectively), after dehydration, filtering solid impurities, and preheating it, according to the crude benzene separation scheme B, from the cutting tower. 1. The middle feed, the tower is operated continuously at normal pressure, and the control tower still temperature is 126 ° C, and the crude benzene is divided into a toluene front fraction (containing toluene fraction) and a toluene rear fraction; wherein the toluene front fraction passes through the benzene-toluene cutting tower again. The separation of benzene front fraction (containing benzene fraction) and toluene is realized, while the toluene rear fraction is separated from xylene through a xylene tower.

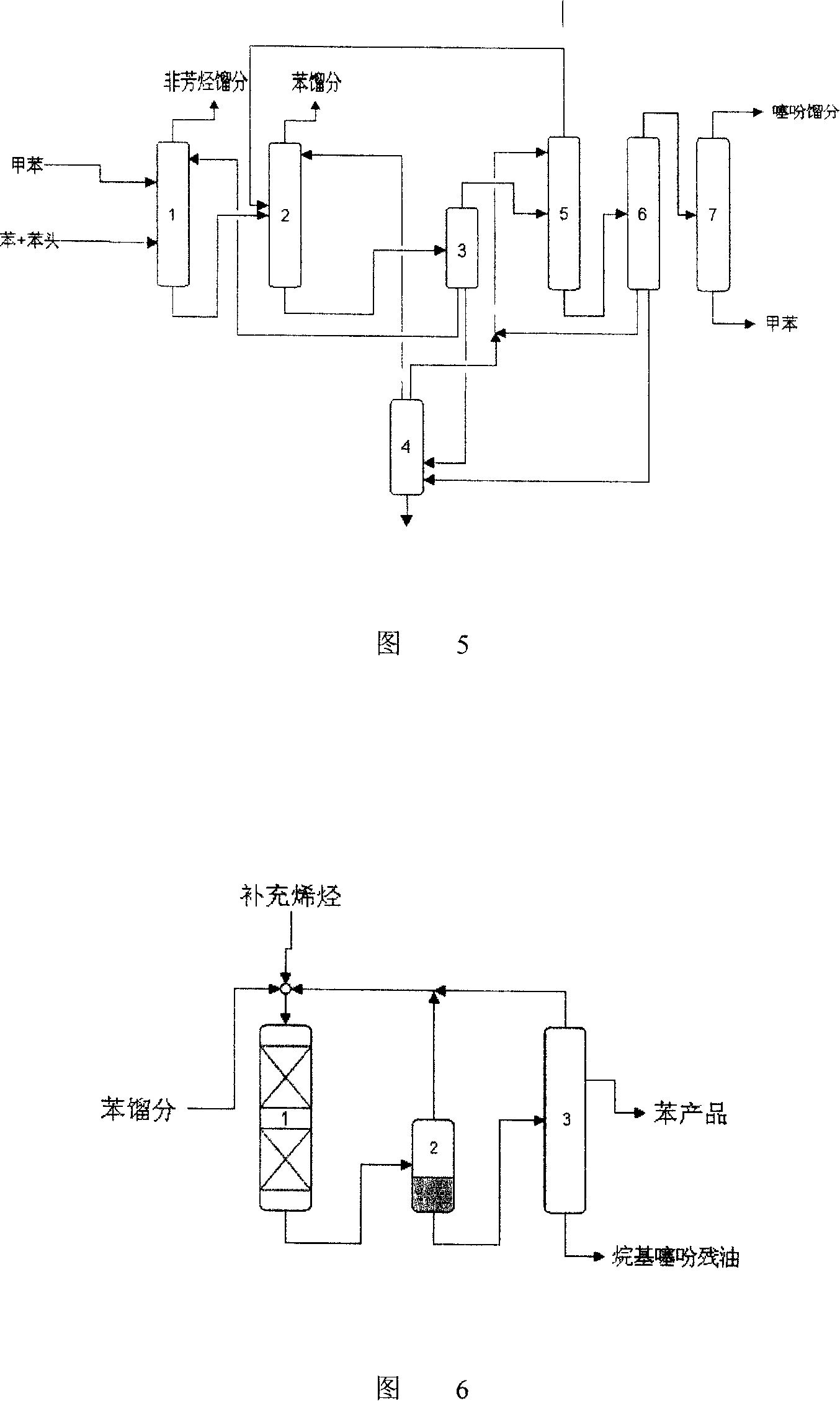

[0055] N-formyl morpholine was selected as solvent, the solvent ratio of the de-aromatic column was 3.5, the reflux ratio was 30, and other operating cond...

Embodiment 3

[0058] Taking the coking crude benzene produced by the coking enterprise as the raw material (wherein the mass contents of benzene and toluene are respectively 68.8% and 12.1%), dewatering and filtering the solid impurities, and preheating it, according to the crude benzene separation scheme C, from the tower 1 The middle feed, the tower is operated continuously at normal pressure, and the crude benzene is divided into benzene front fraction (containing benzene fraction) and distilled from the top of the tower; the bottom fraction is passed through the toluene tower 2 and the xylene tower 3, and the toluene and the xylene fraction are separated by toluene and xylene. seperate.

[0059]Sulfolane was selected as the solvent, the solvent ratio of the non-aromatics tower was 4.3, the operating pressure was 0.23 MPa, the temperature at the bottom of the tower was controlled at 162°C to 165°C, the feed temperature of the lean solvent was 105°C, and other operating conditions were the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com