Method for producing benzene aromatic hydrocarbon from crude benzole

A technology for benzene-based aromatics and crude benzene, which is applied in the production of bulk chemicals, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problems of low yield of aromatic products and large loss of aromatics. , to achieve the effect of high yield, low equipment investment and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

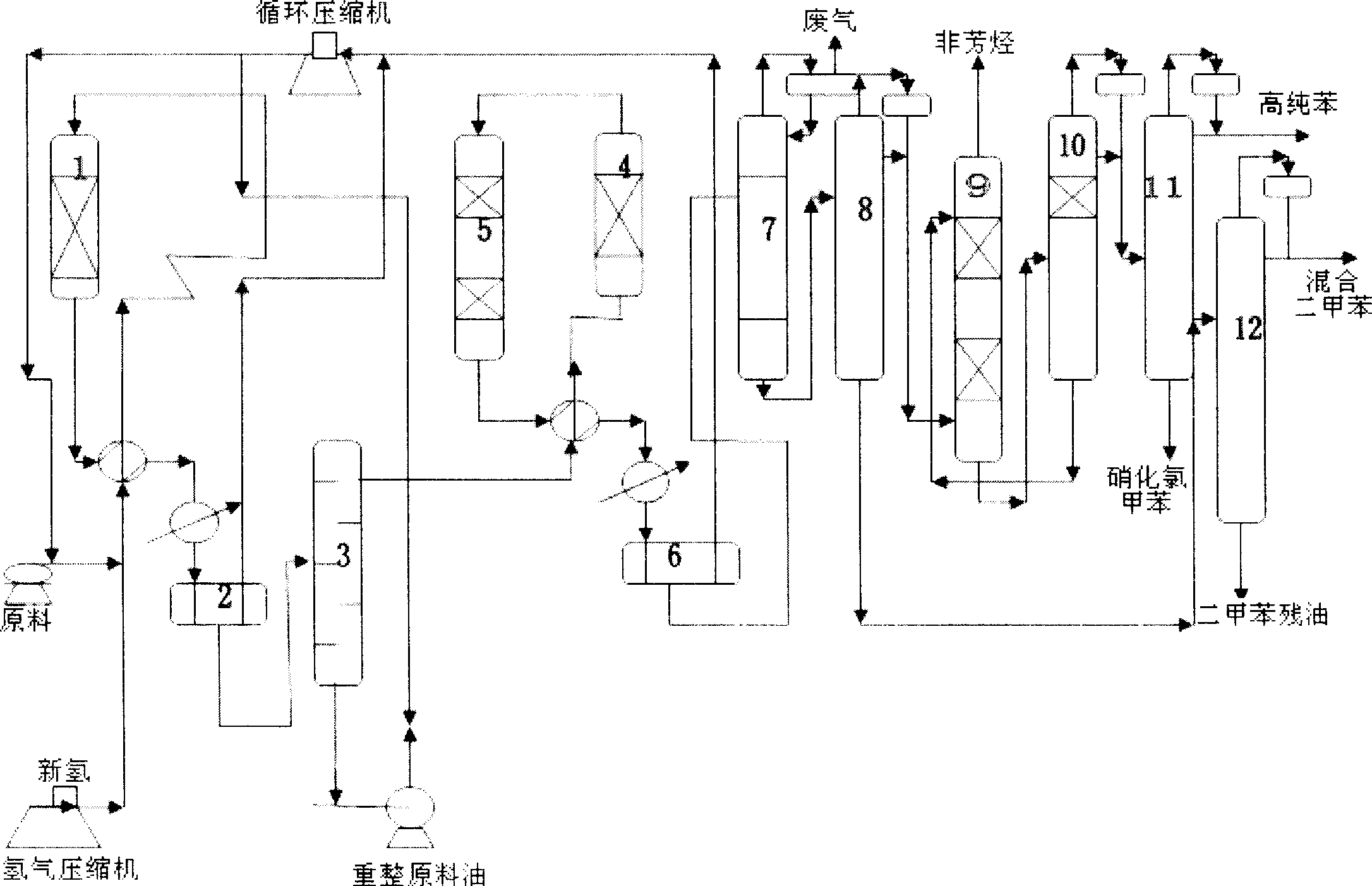

[0026] Crude benzene and catalytic heavy gasoline are mixed in a certain proportion, and their properties are shown in Table 1. After mixing with hydrogen, it enters the hydrogenation reactor 1. The reaction conditions are shown in Table 2. The catalyst is a molybdenum-nickel-tungsten-phosphorus hydrogenation catalyst. The gas-liquid mixture discharged from the hydrogenation reactor enters the gas-liquid separator 2, and the obtained liquid phase is called hydrogenation. The properties of hydrogen oil and hydrogenated oil are shown in Table 2.

[0027] Cut the hydrogenated oil into a distillate with a dry point less than 180°C, and send the distillate to the pre-hydrogenation reactor 4. The pre-hydrogenation reaction conditions are: temperature 320°C, hydrogen pressure 1.2MPa, liquid space velocity 2.0h -1 , the ratio of hydrogen to oil is 1200:1, and the catalyst is molybdenum-cobalt hydrogenation catalyst.

[0028] The pre-hydrogenated refined oil enters the reforming react...

Embodiment 2

[0034] Crude benzene and coker gasoline are mixed in a certain proportion, and their properties are shown in Table 4. See Table 5 for hydrogenation reaction conditions, properties and family composition of hydrogenated oil. Other reaction conditions, reaction steps are with embodiment 1. The properties of the reformate are shown in Table 6. The product properties are shown in Table 9.

[0035]

[0036] Test raw material

[0037] Test raw material

Embodiment 3

[0039] Crude benzene and catalytic diesel are mixed in a certain proportion, and the hydrogenated oil is cut to produce a distillate with a dry point of less than 180°C. The properties of the distillate and the hydrogenation reaction conditions are shown in Table 7. Other reaction conditions, reaction steps are with embodiment 1. The properties of the reformate are shown in Table 8. The product properties are shown in Table 9.

[0040] Test raw material

[0041] color / smell

[0042] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com