Hardening coating and easily torn and located protective film prepared by utilizing hardening coating

A protective film and coating technology, applied in the field of easy-to-tear and easy-to-locate protective film, can solve problems such as uneven color of the display screen, rainbow pattern phenomenon, stains on the rubber surface of the protective film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

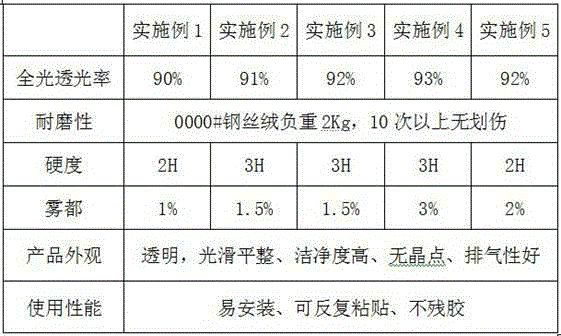

Embodiment 1

[0078] A kind of hardening paint, comprises the raw material of following percentage by weight:

[0080] Urethane acrylate 10%

[0081] Methyl methacrylate 10%

[0082] Butyl Acrylate 10%

[0083] Hydroxyethyl Acrylate 10%

[0085] Benzophenone 3%

[0086] Triethanolamine 2%

[0087] Polysiloxane-polyether copolymer 2%

[0088] EDAB 2%

[0089] Wherein, the curing energy of the hardened coating is 300mj / cm 2 , The curing time is 25s.

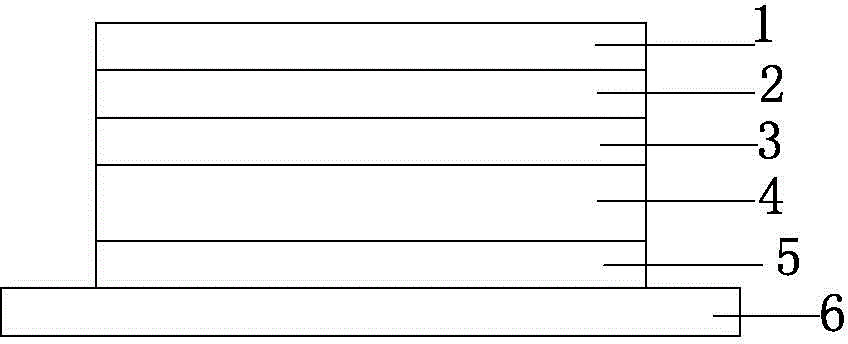

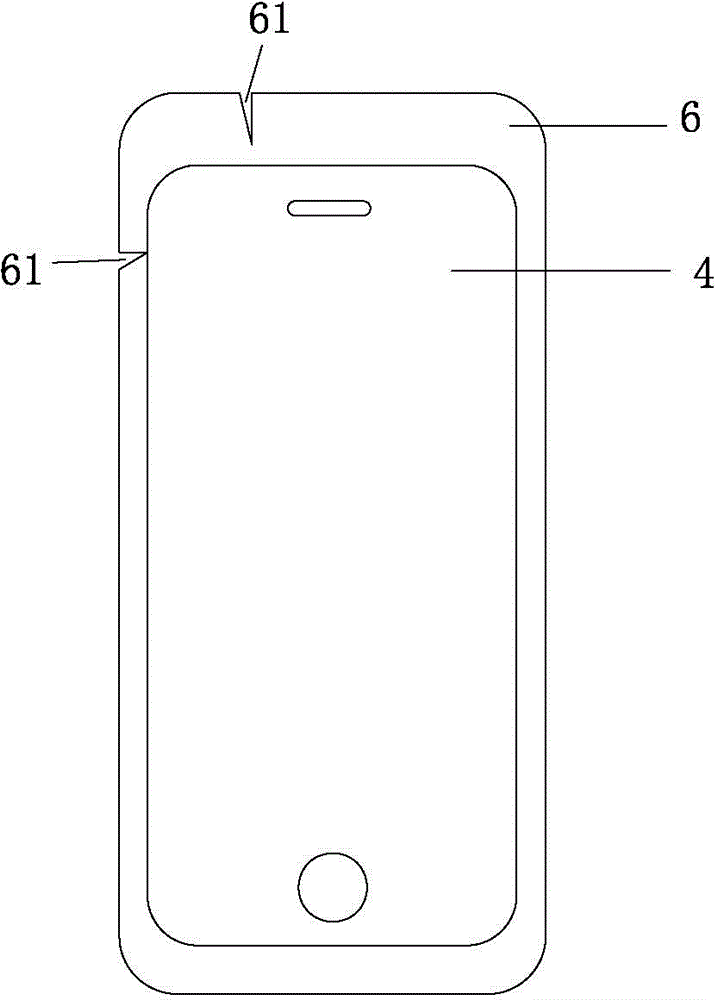

[0090] An easy-to-tear and easy-to-position protective film made by hardening paint, the easy-to-tear and easy-to-position protective film includes a protective film layer 1, a first adhesive layer 2, a main film layer 4, a second adhesive layer 5 and The peeling layer 6 made of easy-to-tear film material, the periphery of the peeling layer 6 stretches out of the periphery of the main film layer 4, and the peripheral edge of the peeling layer 6 is provided with a tear opening 61, an...

Embodiment 2

[0098] A kind of hardening paint, comprises the raw material of following percentage by weight:

[0100] Urethane acrylate 8%

[0101] Methyl methacrylate 8%

[0102] Butyl Acrylate 9%

[0103] Hydroxyethyl Acrylate 8%

[0105] Benzophenone 2%

[0106] Triethanolamine 1.5%

[0107] Polysiloxane-polyether copolymer 1.5%

[0108] EDAB 3%

[0109] Wherein, the curing energy of the hardened coating is 400mj / cm 2 , The curing time is 20s.

[0110] An easy-to-tear and easy-to-position protective film made by hardening paint, the easy-to-tear and easy-to-position protective film includes a protective film layer 1, a first adhesive layer 2, a main film layer 4, a second adhesive layer 5 and The peeling layer 6 made of easy-to-tear film material, the periphery of the peeling layer 6 stretches out of the periphery of the main film layer 4, and the peripheral edge of the peeling layer 6 is provided with a tear opening 61, an...

Embodiment 3

[0118] A kind of hardening paint, comprises the raw material of following percentage by weight:

[0120] Urethane acrylate 7%

[0121] Methyl methacrylate 7%

[0122] Butyl Acrylate 8%

[0123] Hydroxyethyl Acrylate 7%

[0124] Benzoin ether 4.5%

[0125] Benzophenone 2.5%

[0126] Triethanolamine 1%

[0127] Polysiloxane-polyether copolymer 1%

[0128] EDAB 2%

[0129] Wherein, the curing energy of the hardened coating is 500mj / cm 2 , The curing time is 15s.

[0130] An easy-to-tear and easy-to-position protective film made by hardening paint, the easy-to-tear and easy-to-position protective film includes a protective film layer 1, a first adhesive layer 2, a main film layer 4, a second adhesive layer 5 and The peeling layer 6 made of easy-to-tear film material, the periphery of the peeling layer 6 stretches out of the periphery of the main film layer 4, and the peripheral edge of the peeling layer 6 is provided with a tear opening 61, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com