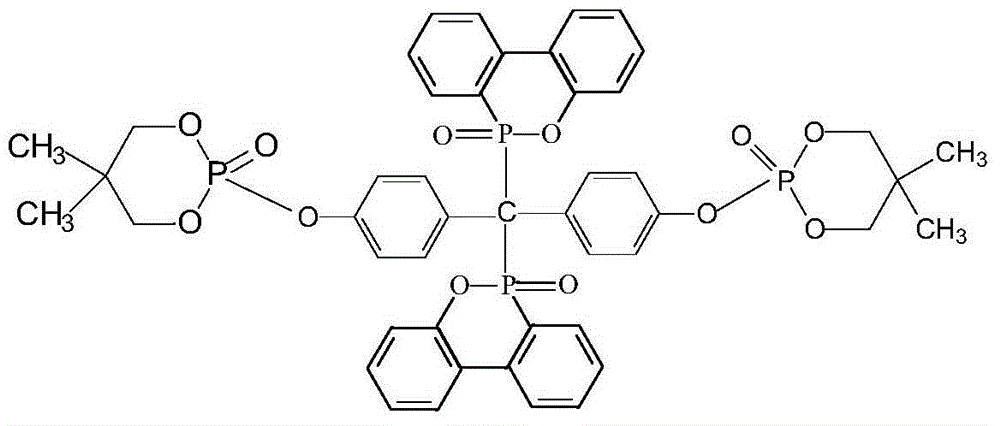

DOPO-containing cyclic phosphate flame retardant as well as preparation method and application thereof

A technology of cyclic phosphate ester and bicyclic phosphate ester, which is used in the preparation of halogen-free flame retardants, dioxycaprolactone phosphate flame retardants, and cyclic phosphate esters. It can solve problems such as the inability to meet the processing temperature of polymer materials. Achieve the effects of easy industrial production, easy access to raw materials, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

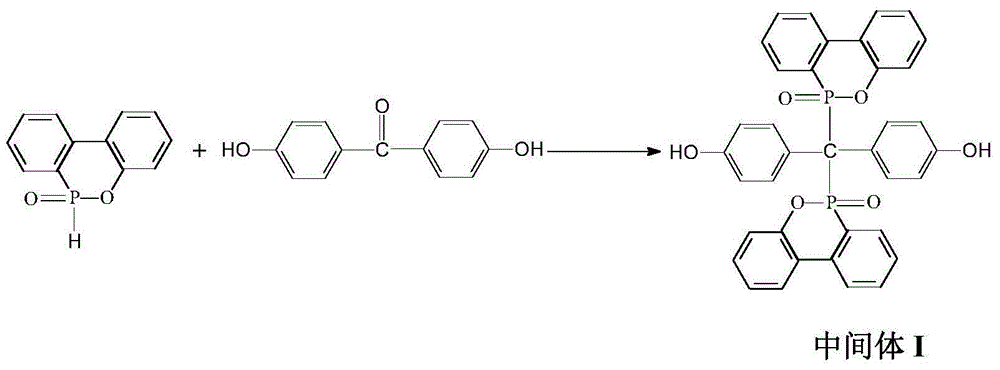

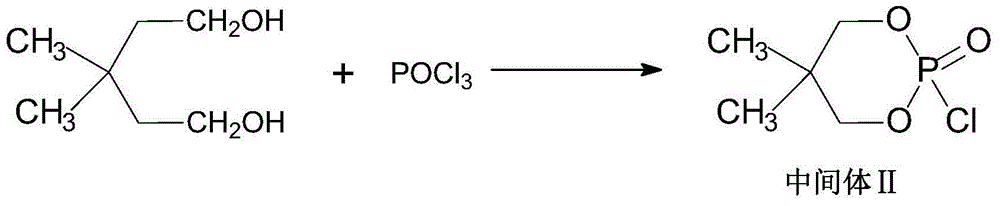

[0023] A preparation method of a DOPO-containing dioxycaprolactophosphate flame retardant, the steps are:

[0024] Into the three-necked flask under the protection of nitrogen, add 4,4 / - 21.4 g (0.10 mol) of dihydroxybenzophenone and 43.2 g of DOPO (0.20 mol) were heated and stirred to 200° C., and stirred for 5 hours. After the reaction was completed, the resulting precipitate was cooled to room temperature and filtered, and was washed with THF-Et 2 O(V THF :V Et2O =7:3) The heavy product was dried to obtain Intermediate I, a white powdery solid, with a yield of 79.5%.

[0025] Add 52.0g (0.5mol) of neopentyl glycol and 200mL of chloroform into the flask, slowly add 84.3g (0.55mol) of phosphorus oxychloride dropwise under stirring, and react at 65°C for 6h after the dropwise addition. After the reaction was completed, chloroform and excess phosphorus oxychloride were distilled off to obtain a white solid, which was recrystallized and dried to obtain intermediate II with...

Embodiment 2

[0033] The solvent in step C was replaced by THF, and the others were the same as Example 1. The yield of the target compound was 82.5%, and the melting point was 282-284°C.

Embodiment 3

[0035] In step C, the solvent was changed to DMAC, and the others were the same as Example 1. The yield of the target compound was 84.3%, and the melting point was 233-235°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com