Flotation method of crystalline uranium ore

A uranium ore and crystalline technology, which is applied in the flotation field of crystalline uranium ore, can solve the problems of low uranium grade and recovery rate, and achieve the effects of reducing production cost, reducing processing capacity and reagent consumption, and high uranium recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

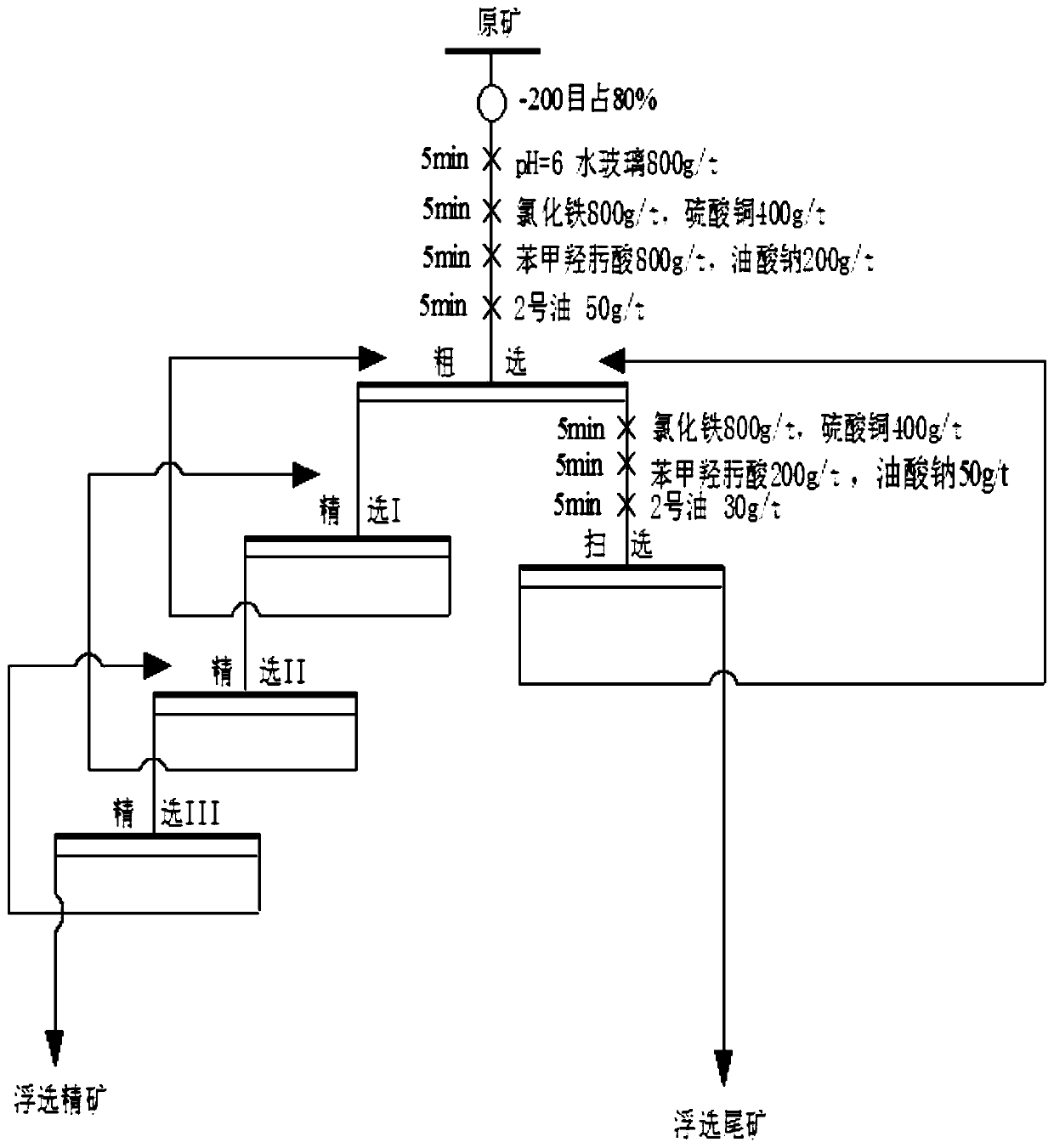

Method used

Image

Examples

Embodiment 1

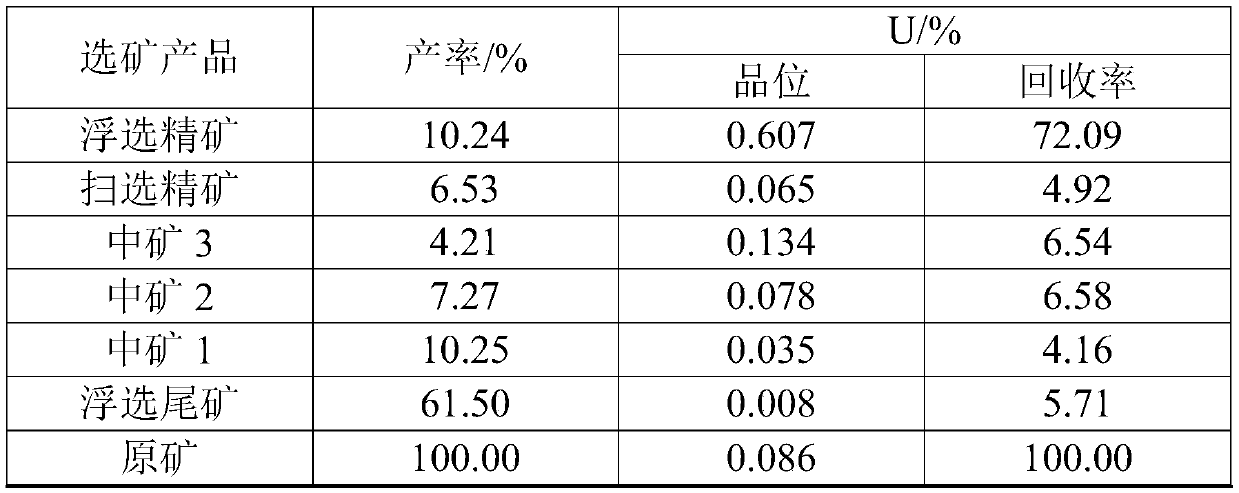

[0039] The main gangue minerals of a pegmatite granite-type uranium ore are microplagioclase, plagioclase, and quartz, with basically equal contents. The content of biotite varies from 5 to 20%, and a small amount of muscovite is occasionally seen. Uranium mainly exists in the form of crystalline uranium ore, which accounts for more than 90% of all uranium-containing minerals, with a uranium grade of 0.087%.

[0040] (1) After crushing the ore to -3mm, grind the ore to a fineness of -200 mesh accounting for 65%, adjust the slurry concentration to 25% of the ore mass fraction, adjust the temperature to 30 °C, and transfer it to the flotation cell.

[0041] (2) Sulfuric acid was added to the pulp, and the pH value of the pulp was adjusted to 5.5.

[0042] (3) Add 600g / t of gangue mineral inhibitor water glass to the slurry, and stir for 15min under the condition of stirring speed of 1900r / min.

[0043] (4) Add crystalline uranium ore activator, ferric chloride 800g / t, copper s...

Embodiment 2

[0049] The main gangue minerals of a pegmatite granite-type uranium ore are microplagioclase, plagioclase, and quartz, with basically equal contents. The content of biotite varies from 5 to 20%, and a small amount of muscovite is occasionally seen. Uranium mainly exists in the form of crystalline uranium ore, which accounts for more than 90% of all uranium-containing minerals, with a uranium grade of 0.087%.

[0050] (1) After crushing the ore to -2mm, grind the ore to a fineness of -200 mesh accounting for 70%, adjust the slurry concentration to 25% ore mass fraction, adjust the temperature to 35°C, and transfer it to the flotation cell.

[0051] (2) Add sulfuric acid to the pulp, and adjust the pH value of the pulp to 6.5.

[0052] (3) Add 800g / t of gangue mineral inhibitor water glass to the slurry, and stir for 5min under the condition of stirring speed of 2000r / min.

[0053] (4) Add 1000g / t of crystalline uranium ore activator ferric chloride and 500g / t of copper sulfate ...

Embodiment 3

[0060] The main gangue minerals of a pegmatite granite-type uranium ore are microplagioclase, plagioclase, and quartz, with basically equal contents. The content of biotite varies from 5 to 20%, and a small amount of muscovite is occasionally seen. Uranium mainly exists in the form of crystalline uranium ore, which accounts for more than 90% of all uranium-containing minerals, with a uranium grade of 0.087%.

[0061] (1) After crushing the ore to -2.5mm, grind the ore to a fineness of -200 mesh accounting for 75%, adjust the slurry concentration to 30% ore mass fraction, adjust the temperature to 35 °C, and transfer it to the flotation cell.

[0062] (2) Sulfuric acid was added to the pulp, and the pH value of the pulp was adjusted to 6.0.

[0063] (3) Add 900 g / t of gangue mineral inhibitor water glass to the slurry, and stir for 5 minutes under the condition of a stirring speed of 2000 r / min.

[0064] (4) Add crystalline uranium ore activator ferric chloride 1200g / t and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com