A high-efficiency beneficiation and impurity removal process and combined agent for complex and refractory potassium albite ore

A technology of potassium sodium feldspar and combined agent, applied in the field of comprehensive utilization of resources, can solve the problems of high iron content, the whiteness of feldspar or the whiteness of sintering can not meet the requirements and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

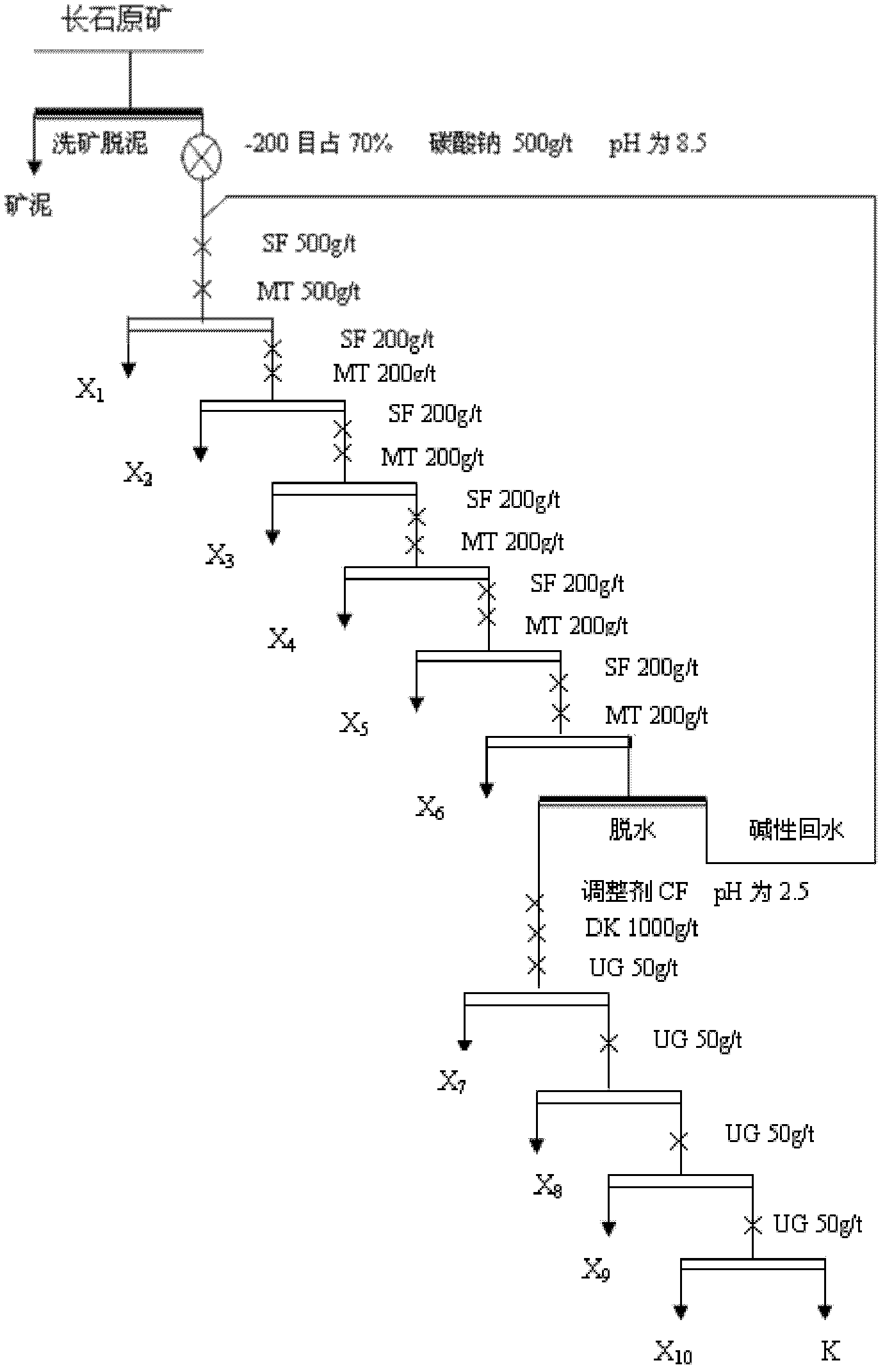

[0030] For the pegmatite low-grade feldspar ore in a certain place in Hunan, the above-mentioned process was used for beneficiation and removal of impurities. See the experimental procedure figure 1 . The whiteness of the feldspar raw ore is about 25 when it is directly fired. After the new process of flotation to remove impurities, the number of flotation stages is 10 times. figure 1 , the whiteness of the final direct burning of the concentrate can reach more than 59, and the yield is about 70%. The results are shown in Table 1. It can be seen from the results that the final removal rate of impurities such as titanium and iron can reach 95.5% by adopting the combination agent system of the present invention, and the effect is more obvious.

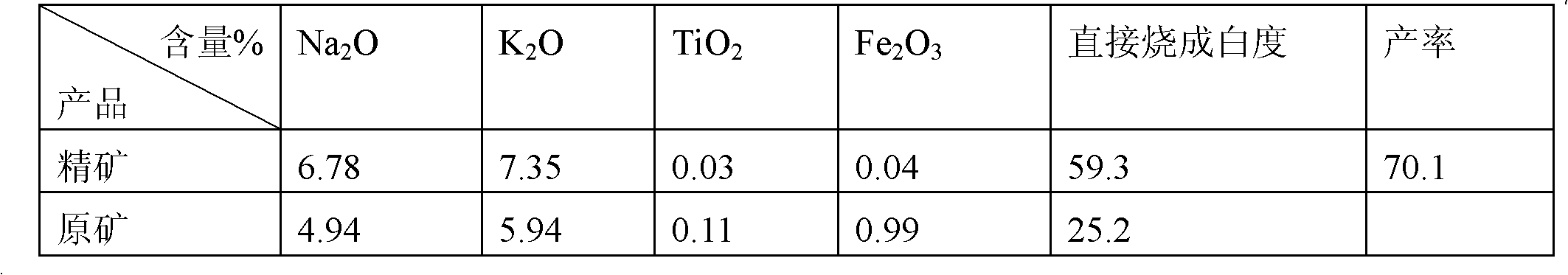

[0031] Table 1. Results of new process of flotation and impurity removal in a feldspar mine in Hunan

[0032]

Embodiment 2

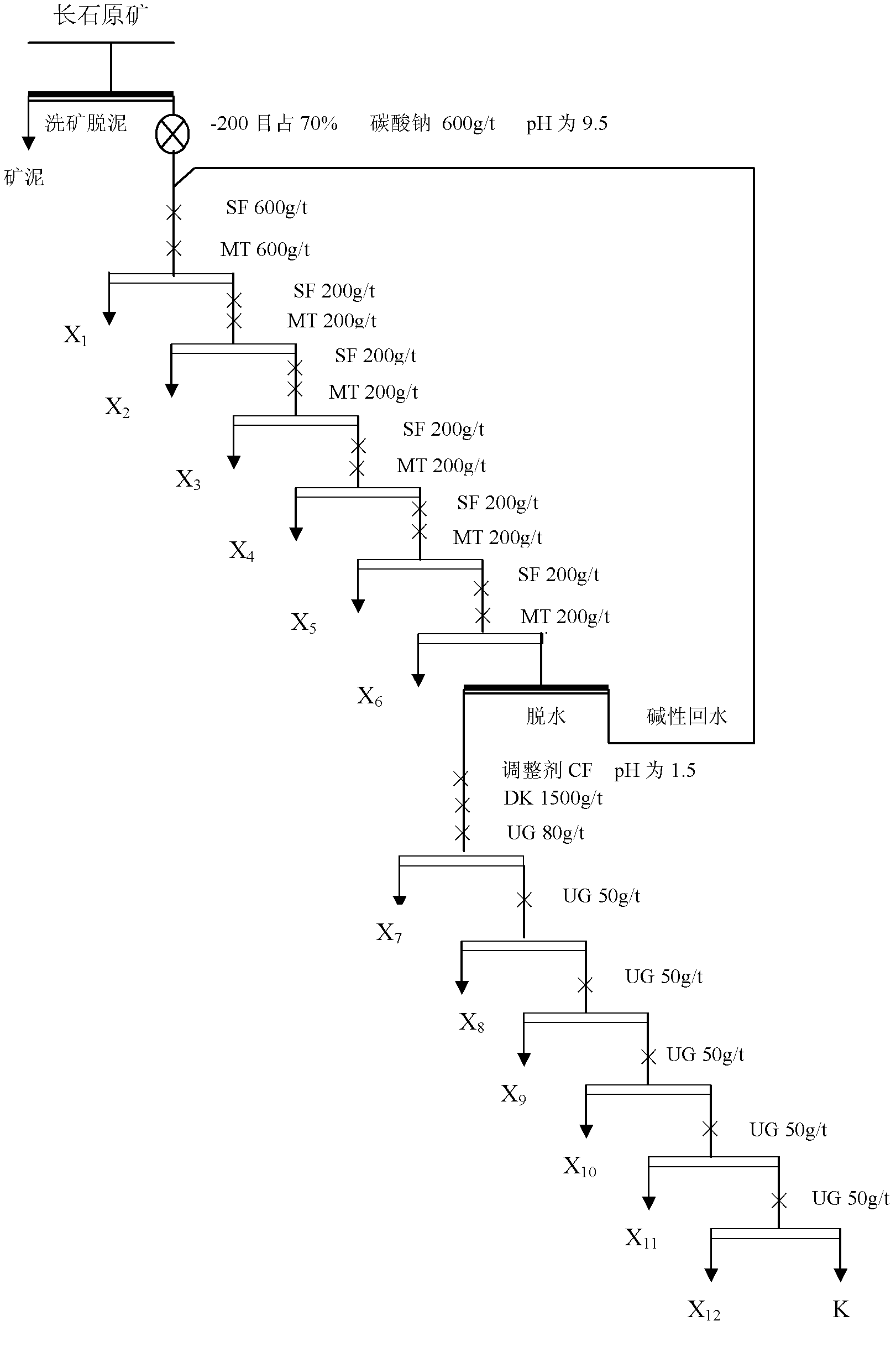

[0034] Aiming at the pegmatite granite low-grade potassium albite ore in a certain place in Jiangxi, the above-mentioned process was used for beneficiation and removal of impurities. For the experimental process and the times and amounts of reagents added during the flotation process, please refer to figure 2. The feldspar raw ore is directly fired with a whiteness of about 11. After the new process of flotation to remove impurities, the number of flotation stages is 12, and the concentrated ore is directly fired with a whiteness of more than 50, and the yield is about 65%. The results are shown in the table. 2. It can be seen from the results that the final removal rate of impurities such as titanium and iron can reach 93.4% by using the combination agent system described in the present invention, and the effect is better.

[0035] Table 2. The results of the new process of flotation and impurity removal in a feldspar mine in Jiangxi

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com