Copper-ammonia complex ion sulfuration activator and application thereof

A vulcanization activator and complex ion technology, which is applied in cuproammonia complexes, copper oxide/copper hydroxide, solid separation, etc., can solve the problem of low flotation recovery rate of copper oxide ore, reduce the dosage of chemicals and save costs , the effect of high flotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1, the preparation of copper ammonium ion vulcanization activator: measure 10ml concentration and be the copper sulfate solution of 0.02mol / L, slowly add the concentrated ammonia water of 8mol / L in copper sulfate solution, stop adding until solution pH reaches 6.3, obtain NH 4 + :Cu 2+ A solution of copper ammonium ions in a ratio of 2:1.

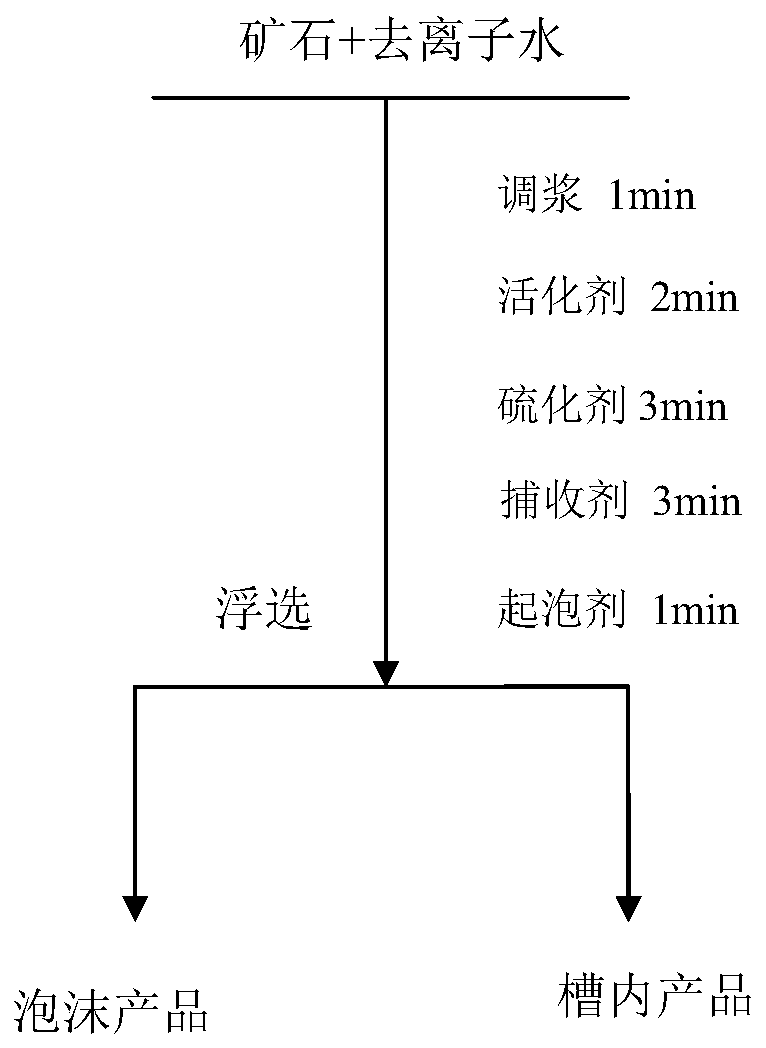

[0030] 2. Flotation test: the flotation test adopts a hanging cell type flotation machine (laboratory flotation machine), the volume of the flotation cell is 40ml, the flotation machine speed is 1450r / min, and the flotation temperature is normal temperature. Weigh 2.0g of malachite and pour it into the flotation tank, add 35ml of deionized water, stir and adjust the slurry for 1min, so that the pH of the slurry is 7, set up two groups of experiments respectively, the experimental group is to add 1mL of vulcanization enhancer copper ammine ion solution The same amount of deionized water was added to the control group, and the actio...

Embodiment 2

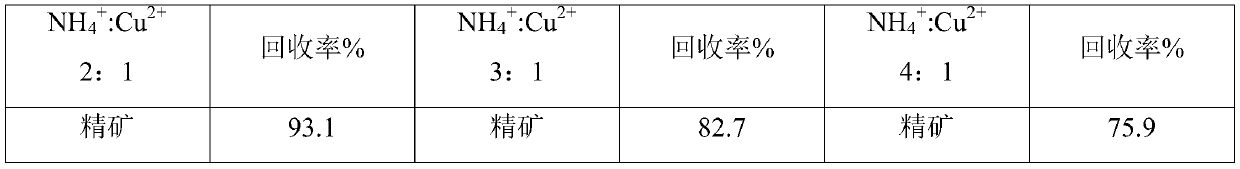

[0034] 1. Preparation of copper ammonium ion vulcanization activator: measure 10ml of copper sulfate solution with different concentrations, slowly add 8mol / L concentrated ammonia water to the copper sulfate solution, stop adding until the pH of the solution reaches 6.3, and obtain NH 4 + :Cu 2+ A solution of copper ammine ions in a ratio of 2:1 / 3:1 / 4:1.

[0035] 2. Flotation test: The flotation test adopts a hanging cell type flotation machine, the volume of the flotation cell is 40ml, the speed of the flotation machine is 1450r / min, and the flotation temperature is normal temperature. Weigh 2.0g of malachite and pour it into the flotation tank, add 35ml of deionized water, stir and adjust the slurry for 1min, so that the pH of the slurry is 7, set up three groups of experiments respectively, the experimental group is to add 1ml of NH 4 + :Cu 2+ The copper ammonium ion solution with a ratio of 2:1 was used as a vulcanization enhancer, and the two groups of the control gro...

Embodiment 3

[0040] 1, the preparation of copper ammonium ion vulcanization activator: measure 10ml concentration and be the copper sulfate solution of 0.02mol / L, slowly add the concentrated ammonia water of 8mol / L in copper sulfate solution, stop adding until solution pH reaches 6.3, obtain NH 4 + :Cu 2+ A solution of copper ammonium ions in a ratio of 2:1.

[0041] 2. Flotation test: Weigh 2.0g of malachite and pour it into the flotation tank of the flotation machine, add 35ml of deionized water, stir and adjust the slurry for 1min, so that the pH of the slurry is 7. Three groups of experiments were set up respectively, one group was added with 1ml of copper ammonium ion vulcanization activator, that is, the amount of ammonium ion in the pulp was 1×10 -3 mol / L, the optimal amount of adding ammonium sulfate to strengthen vulcanization in the second group is 5×10 -3 mol / L, the best dosage of adding ethylenediamine phosphate in three groups is 4×10 -3 mol / L. After 2 minutes of activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com