Flotation method for removing potassium from potassium-containing bauxite

A bauxite and potassium removal technology, applied in flotation, solid separation and other directions, can solve the problems of difficult industrial application and complex process, and achieve the effect of improving output and quality, and achieving significant economic and environmental benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Embodiment 1: the flotation method of potassium-containing bauxite depotassium described in the present invention

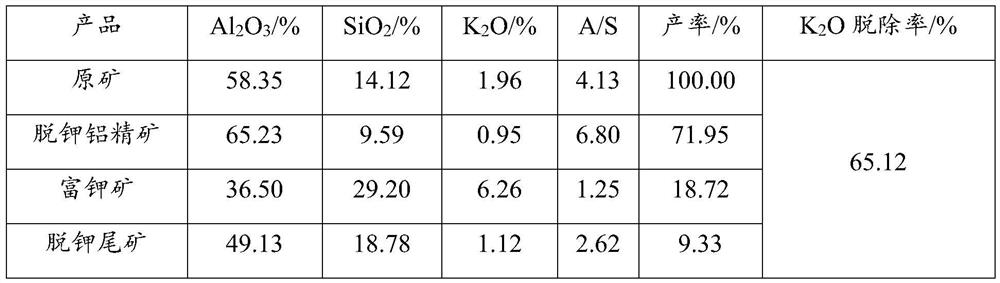

[0104] A potassium-containing bauxite mine in Guizhou, in which the raw ore K 2 O content is 1.96%, Al 2 o 3 Content is 58.35%, SiO 2 The content is 14.12%, and the A / S is 4.13.

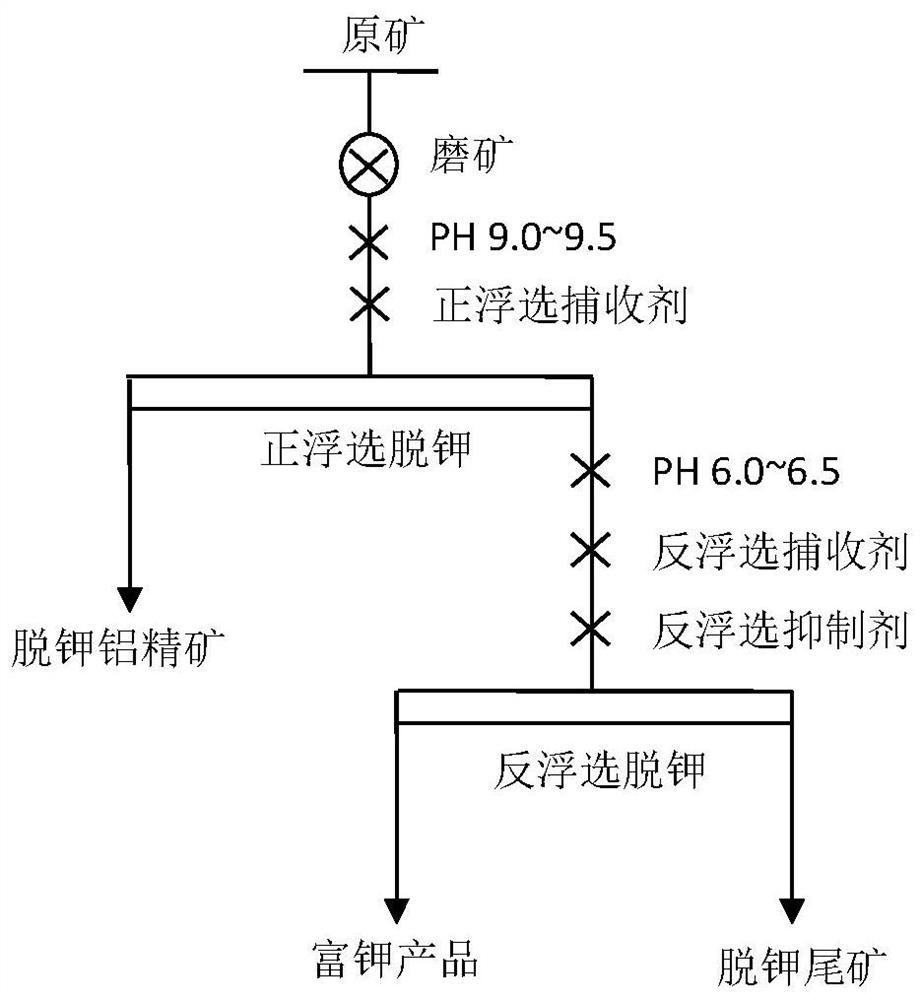

[0105] The flotation method of potassium-containing bauxite depotassium described in the present invention comprises the following steps:

[0106] (1) Grinding the potassium-containing bauxite to a fineness of -0.074mm accounts for 92.36% of the total mass;

[0107] (2) adjust the pH value of the slurry of the potassium-containing bauxite obtained in step (1), and then use a positive flotation depotassium collector to carry out positive flotation depotassiation to obtain a yield of 71.95%, and the A / S is 6.8 、K 2 Foam product with an O content of 0.95%, as depotassium aluminum concentrate, where K 2 O removal rate was 65.12%, the results are shown in Table 1;

[0108] W...

Embodiment 2

[0113] Embodiment 2: the flotation method of potassium-containing bauxite depotassium described in the present invention

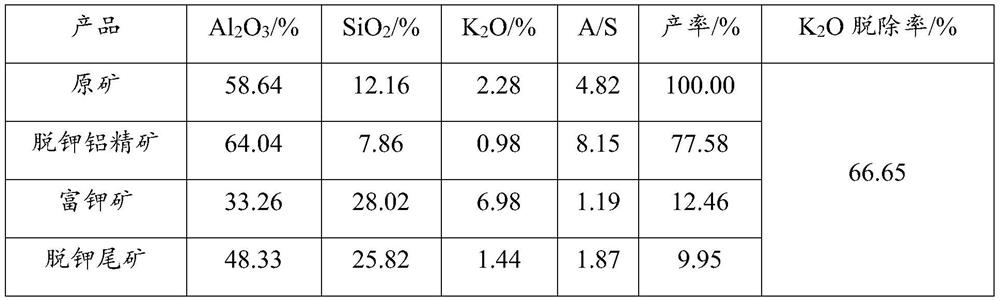

[0114] A potassium-containing bauxite mine in Guizhou, where K 2 O content is 2.28%, Al 2 o 3 Content is 58.64%, SiO 2 The content is 12.16%, and the A / S is 4.82;

[0115] The flotation method of potassium-containing bauxite depotassium described in the present invention comprises the following steps, can refer to figure 1 :

[0116] (1) Grinding the potassium-containing bauxite to a fineness of -0.074mm accounts for 90.92% of the total mass;

[0117] (2) The pH value of the slurry of the potassium-containing bauxite obtained in step (1) is adjusted to 9.5, and the positive flotation depotassium collector is used to carry out positive flotation depotassium after 1 roughing, 3 refinements Election, 1 time of sweeping, positive flotation underflow was obtained, and the yield was 77.58%, A / S was 8.15, K 2 Foam product with an O content of 0.98%, as d...

Embodiment 3

[0127] Embodiment 3: the flotation method of potassium-containing bauxite depotassium described in the present invention

[0128] A potassium-containing bauxite mine in Henan, raw ore K 2 O content is 1.62%, Al 2 o 3 Content is 56.52%, SiO 2 The content is 14.08%, and the A / S is 4.01.

[0129] The flotation method of potassium-containing bauxite depotassium described in the present invention comprises the following steps:

[0130](1) Grinding the potassium-containing bauxite to a fineness of -0.074mm accounts for 85% of the total mass;

[0131] (2) Adjust the pH value of the slurry of the potassium-containing bauxite obtained in step (1) to 9.0, and then use a positive flotation depotassium collector to carry out positive flotation depotassiation. election, 3 sweeps, the yield was 72.66%, A / S was 6.84, K 2 O content is the foam product of 0.77%, and the results are shown in Table 3;

[0132] Wherein, the positive flotation depotassiation collector comprises sodium ole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com