Method for detecting benzohydroxamic acid in flour and flour improver

The technology of flour improver and benzohydroxamic acid, which is applied in the field of analytical chemistry, can solve the problems of unused flour and flour improver research, etc., and achieves the effects of good dissolution effect, accurate qualitative and satisfying detection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

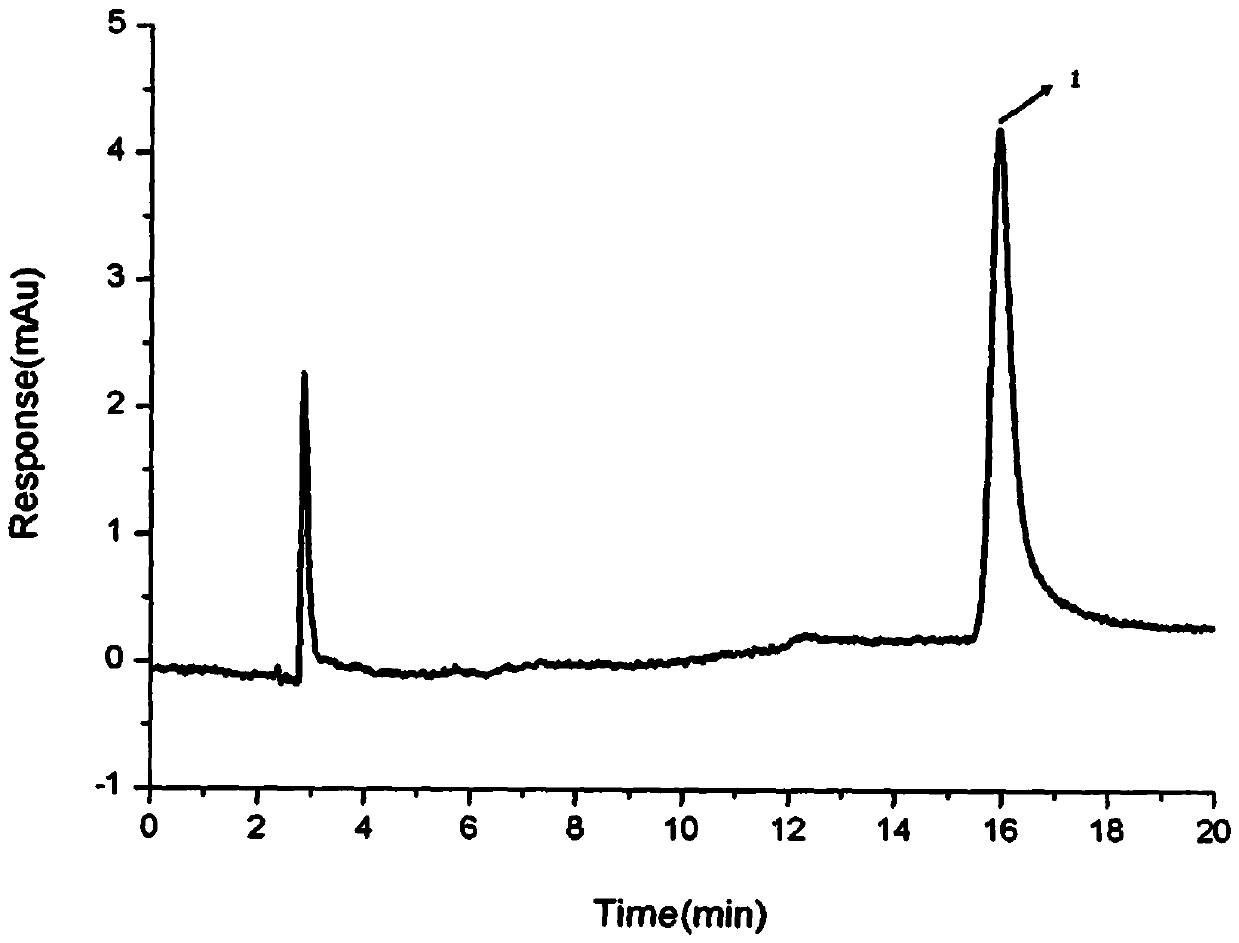

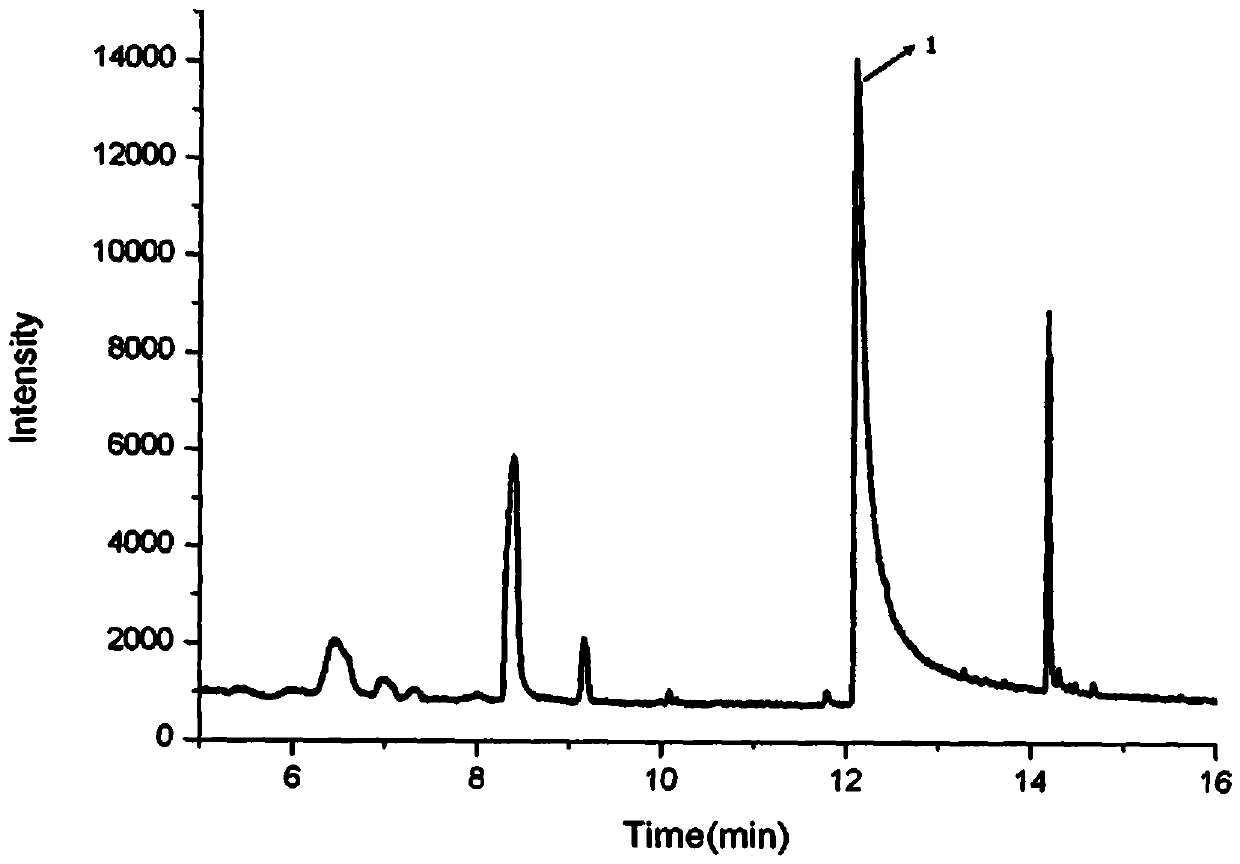

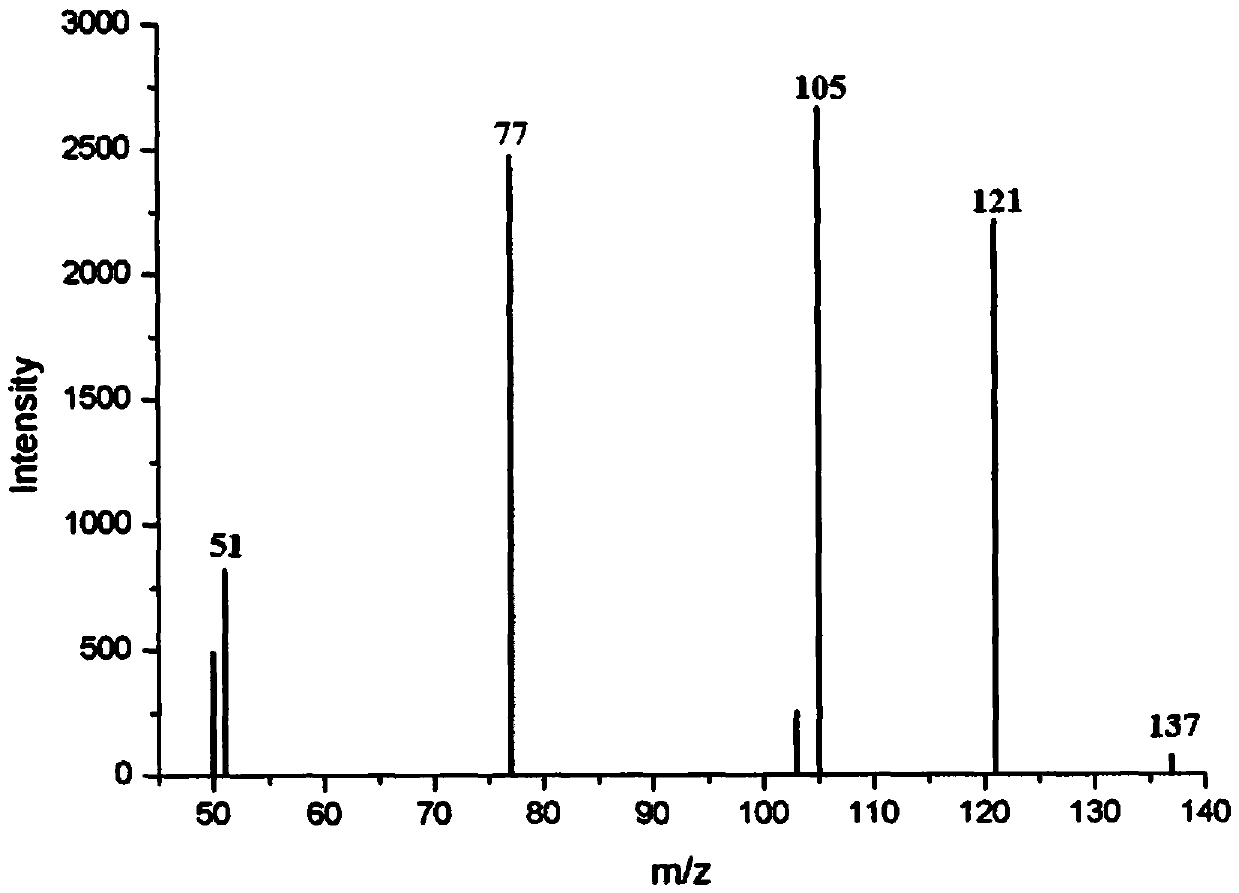

[0025] 1 μg / mL standard solution of benzohydroxamic acid, accurate injection of 50 μL, separated by Shimadzu InertSustain C18 (250 mm×4.6 mm, 5 μm) chromatographic column, gradient elution of methanol and pH 2.5 18 mM potassium dihydrogen phosphate solution, The elution procedure is shown in Table 1; the flow rate is 1mL / min, the column temperature is 30°C, and the wavelength of the ultraviolet detector is 228nm. According to the above liquid chromatography conditions, the retention time of benzohydroxamic acid is 16.12min.

[0026] Table 1 Gradient elution program

[0027]

Embodiment 2

[0029] Weigh 2.0g (accurate to 0.01g) of uniform flour, add 8mL of methanol / water (6:4, volume ratio) solution, vortex to mix, ultrasonically extract for 20min, and centrifuge at 4000r / min for 3min; Measurement; Different pH values have a greater impact on impurities in wheat flour. At pH 2.0, the separation of target and sample impurities is <1.5; at pH 2.5, the separation of target and sample impurities is 4.85; at pH 3.0, The separation degree of target object and sample impurity is 4.70; at pH4.0, the separation degree of target object and sample impurity is 3.35; Potassium hydrogen was used as the mobile phase to separate benzohydroxamic acid and wheat flour impurities best. The retention time of benzohydroxamic acid was 16.12 min, and the retention time of the impurity peak in wheat flour was 18.45 min.

Embodiment 3

[0031] Weigh 2.0g (accurate to 0.01g) uniform flour sample into a 50mL plastic centrifuge tube, add 0.1mL of 100 μg / mL benzohydroxamic acid standard intermediate solution, let stand for a period of time, add 8mL of different ratios of methanol / Aqueous solution (volume ratios are 10:0, 9:1, 8:2, 7:3, 6:4, 5:5, 4:6, 3:7, 2:8, 1:9, 0:10) , vortexed, ultrasonically extracted for 20 minutes, and centrifuged at 4000r / min for 3 minutes; the supernatant was passed through the membrane and then tested; according to the above liquid chromatography conditions, the retention time of the target peak in the sample was consistent with that of the standard product, and the volume ratio of methanol / water When it is 6:4, the recovery rate is the highest, which is 84.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com