Comprehensive recycling process for associated tantalum-niobium ores

A technology of tantalum-niobium ore and tantalum-niobium, which is used in solid separation, wet separation, chemical instruments and methods, etc., can solve the problem that valuable metals cannot be reasonably recycled, the grade of tantalum-niobium concentrate is low, and the embedded particle size is uneven. and other problems, to achieve the effect of strong selectivity and collection ability, good mineral processing index and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

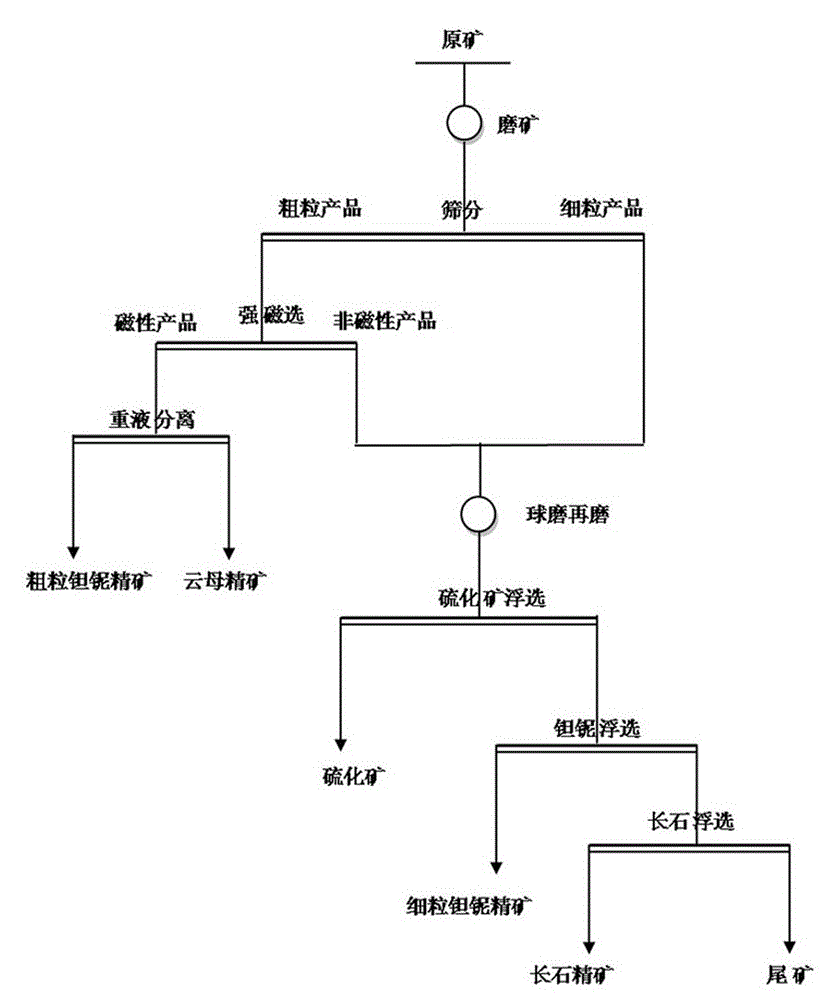

Image

Examples

Embodiment 1

[0021] An associated tantalum-niobium ore in Gansu 2 o 5 Grade 29.6g / t, Nb 2 o 5 The grade is 104g / t. Tantalum and niobium mainly exist in the form of niobium-tantalite. The distribution of tantalum-niobite is uneven in size, with coarse grains greater than 0.15mm and fine grains less than 0.037mm. In addition to tantalum-niobium, rare metals are also associated in the ore Rubidium, Rb 2 The O grade is 0.14%. The main minerals in the ore are biotite, potassium feldspar, quartz, and a small amount of sulfide. The particle size of biotite is relatively coarse, mostly greater than 0.15mm. Rubidium occurs in biotite and feldspar.

[0022] The recovery process of the ore for tantalum, niobium and rare metals is as follows:

[0023] 1) Grinding: After the raw ore is wet-ground to a fineness of -0.074mm and accounts for 45%, the grinding concentration is 55%;

[0024] 2) Screening: use a 75-mesh sieve to screen and classify the wet-milled pulp;

[0025] 3) Magnetic separation o...

Embodiment 2

[0030] The main minerals in an associated tantalum-niobium ore in Jiangxi are lepidolite, albite, quartz and a small amount of sulfide. The tantalum-niobium minerals mainly exist in the form of niobium-tantalum-manganese ore. 2 o 5 Grade 87.23g / t, Nb 2 o 5 The grade is 97.58g / t, the particle size of tantalum and niobium intercalation is very different, the coarse particle is more than 0.2mm, and the fine particle is less than 0.037mm. The ore is also accompanied by rare metal lithium, which exists in iron lepidolite. Li 2 O grade is 0.087%.

[0031] The recovery process of the ore for tantalum, niobium and rare metals is as follows:

[0032] 1) Grinding: the raw ore is wet-ground to a fineness of -0.074mm, accounting for 40%, and the grinding concentration is 60%;

[0033] 2) Screening: use a 120-mesh sieve to screen and classify the wet-milled pulp;

[0034] 3) Magnetic separation of coarse-grained products: coarse-grained products on the sieve are fed into a high-gradie...

Embodiment 3

[0039] The main minerals in an associated tantalum-niobium ore in Inner Mongolia are biotite, iron lepidolite, potassium feldspar, quartz, and tantalum-niobium minerals mainly exist in the form of niobium-tantalite. 2 o 5 Grade 70.77g / t, Nb 2 o 5 The grade is 135.37g / t, the particle size of tantalum and niobium intercalation is very different, the coarse particle is more than 0.15mm, and the fine particle is less than 0.037mm. The ore is also accompanied by rare metals lithium and rubidium. Lithium occurs in iron lepidolite, and rubidium occurs in biotite and potassium feldspar, Rb 2 O grade 0.12%, Li 2 O grade 0.041%.

[0040] The recovery process of the ore for tantalum, niobium and rare metals is as follows:

[0041] 1) Grinding: After the raw ore is wet-ground until the fineness-0.074mm accounts for 45%, the grinding concentration is 50%; 2) Screening: Use a 140-mesh sieve to sieve and classify the wet-grinded pulp;

[0042] 3) Magnetic separation of coarse-grained p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com