Continuous production method for separating acetic acid from water by azeotropic distillation

A technology of azeotropic distillation and production method, which is applied in the field of continuous production of acetic acid and water separated by azeotropic distillation, which can solve the problems of large circulation loss of azeotropic agent and failure of automatic control, etc., and achieve good technical effect and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

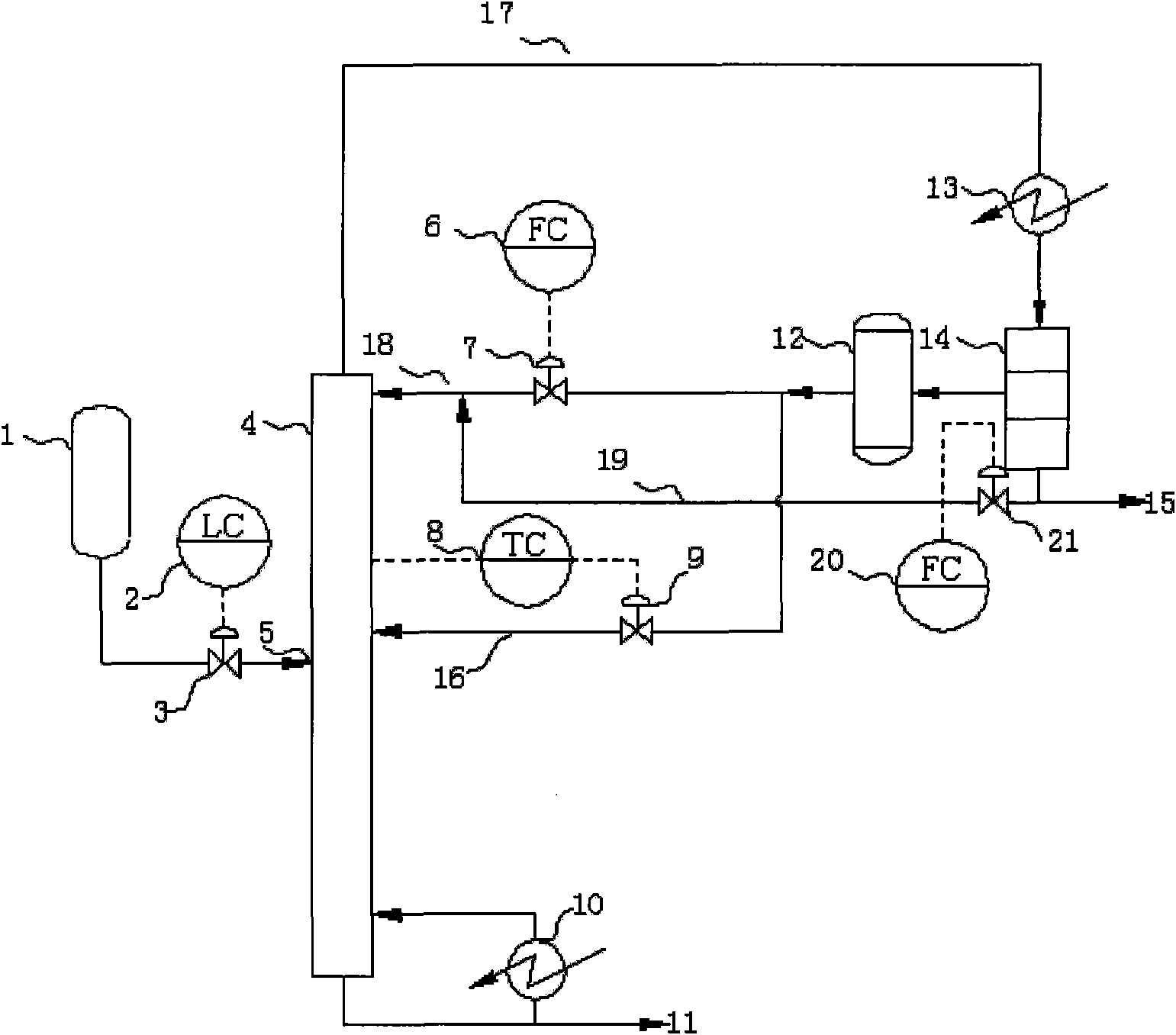

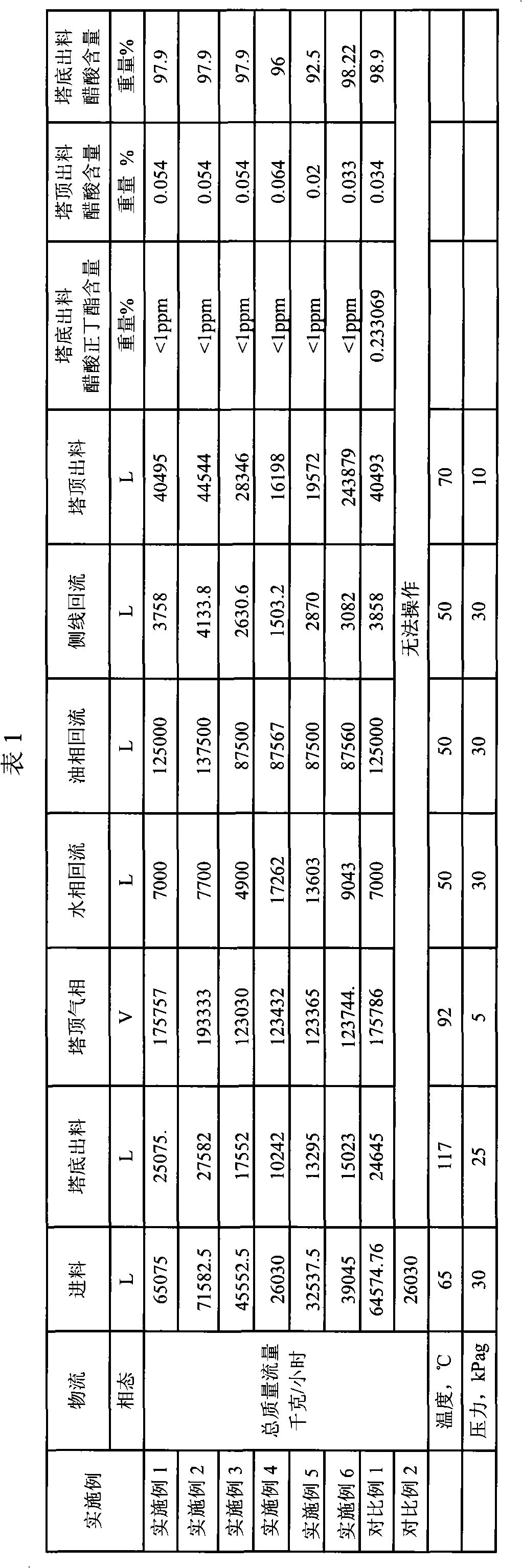

[0033] use figure 1 process shown. In terms of weight percentage, the feed composition is 61.5% of water, 37.8% of acetic acid, and the rest is methyl acetate and p-xylene. The rectification column has 60 plates (equivalent to 36 theoretical plates), the feed position is 36# plate, and the sensitive plate position is 27# plate. The feed rate is 100% of the normal load. The reflux flow of the side line is 3758 kg / h, the reflux flow of the oil phase at the top of the tower is 125000 kg / h, and the reflux flow of the water phase at the top of the tower is 7000 kg / h. The logistics situation and control effect are shown in Table 1.

[0034] The internal parts of the rectification column adopt sieve plate. According to the conventional design, the plate spacing is 550 mm, the tower diameter is 5200 mm, the opening ratio is 10%, and the double flow type, the lower limit of the vapor phase flow rate is 68% of the normal vapor phase lower limit.

[0035] The reflux rate and the fee...

Embodiment 2

[0037] use figure 1 process shown. In terms of weight percentage, the feed composition is 61.5% of water, 37.8% of acetic acid, and the rest is methyl acetate and p-xylene. There are 60 plates in the rectification column, the feeding position is 36# plate, and the sensitive plate position is 27# plate. The feed rate was 110% of normal load.

[0038] The feed flow rate of the rectification tower is uniformly cascade controlled through the liquid level controller 2 of the acetic acid intermediate tank 1 . The return flow of the side line is controlled according to the temperature of the sensitive plate, R OB = 4133.8. The return flow of the oil phase at the top of the tower is controlled by feedforward, and the total return flow of the oil phase R O f F ×A W × K = 71582.2 × 61.5% × 3.19 = 141413.8, the return flow rate of the oil phase at the top of the tower is R OA =R O -R OB =141413.8-4133.8=137500. The reflux flow of the water phase at the top of the tower is cont...

Embodiment 3

[0042] use figure 1 process shown. In terms of weight percentage, the feed composition is 61.5% of water, 37.8% of acetic acid, and the rest are entrainer methyl acetate and a small amount of p-xylene. There are 60 plates in the rectification column, the feeding position is 36# plate, and the sensitive plate position is 27# plate. The feed rate was 70% of the normal load.

[0043] The feed flow rate of the rectification tower is uniformly cascade controlled through the liquid level controller 2 of the acetic acid intermediate tank 1 . The return flow of the side line is controlled according to the temperature of the sensitive plate, R OB =2630. The return flow of the oil phase at the top of the tower is controlled according to the flow rate of 70% of the normal load, and the return flow of the oil phase at the top of the tower is R OA =87500. Return flow rate of water phase at the top of the tower R W =R O ×K2=90130.6×0.054=4900.

[0044] The design of rectifying colu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com