Oil-immersed transformer low-voltage winding structure adopting transposed conductors

An oil-immersed transformer and transposition wire technology, applied in the field of transformers, can solve the problems of complex structure, difficult winding process, large eddy current loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

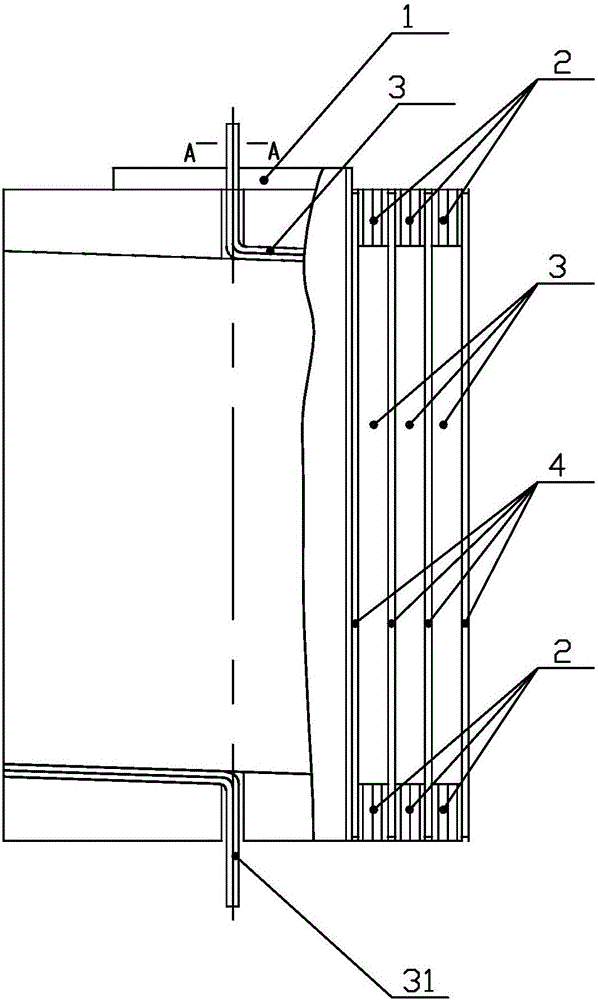

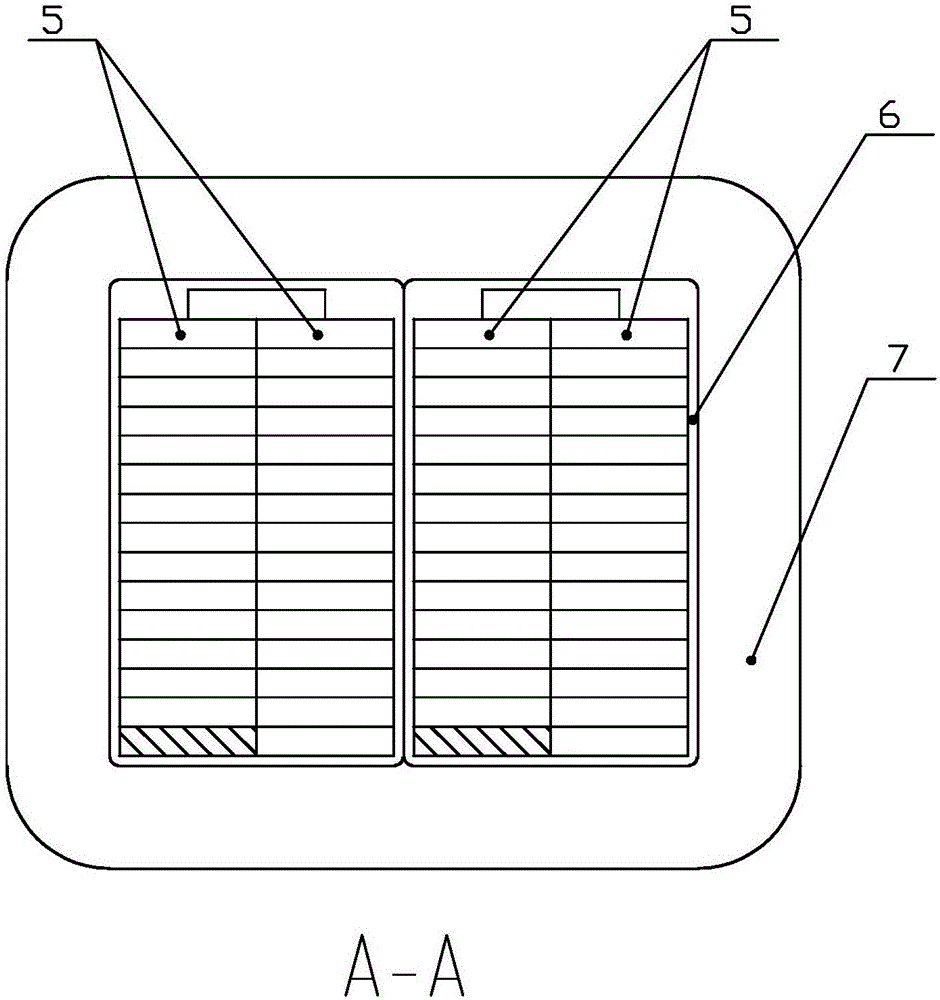

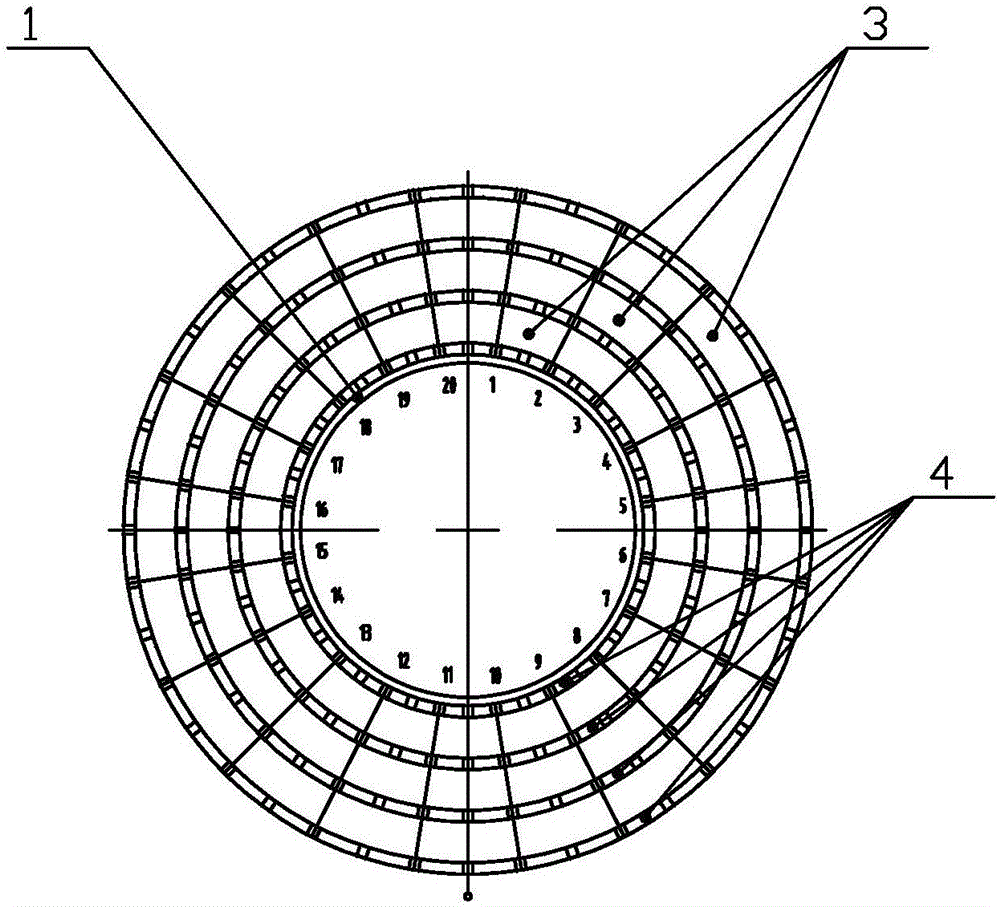

[0023] Specific embodiments of the present invention such as figure 1 , 3 Shown is the low-voltage winding structure of a 110kV oil-immersed transformer using transposed wire 3. The low-voltage winding is cylindrical and includes an insulating cylinder 1. The insulating cylinder 1 includes a cardboard tube, and the cardboard tube is covered with glass fibers. Composition, the transposition conductor 3 is wound on the cardboard tube turn by turn and layer by layer, the transposition conductor 3 in this embodiment is wound in three layers, in this embodiment, two transposition conductors 3 are wound side by side, and At the positions where the two ends of the transposed wires 3 protrude, the outer peripheries of the extruded ends 31 of the two parallel transposed wires 3 are then wrapped with a layer of insulating outer wrapping 7 to form a structure of the extruded ends 31 of a wire. The two ends of the above-mentioned transposition conductors 3 of each layer are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com