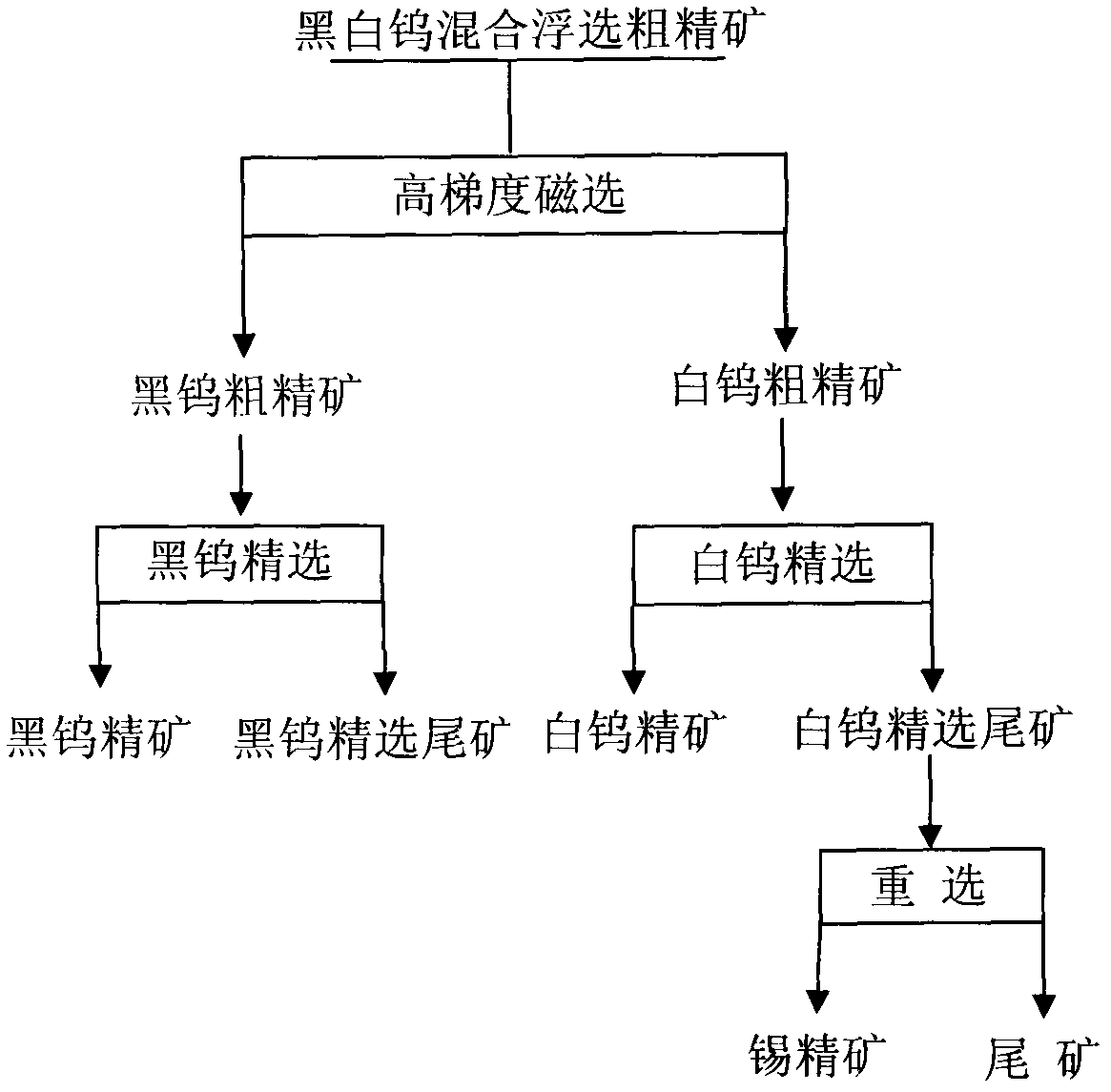

Method for separating black and white tungsten bulk flotation rough concentrates

A technology of mixed flotation and separation methods, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problem of wolframite selection recovery rate, low grade of wolframite concentrate, difficulty and instability of wolframite recovery and other problems, to achieve the effect of high recovery rate, easy activation and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

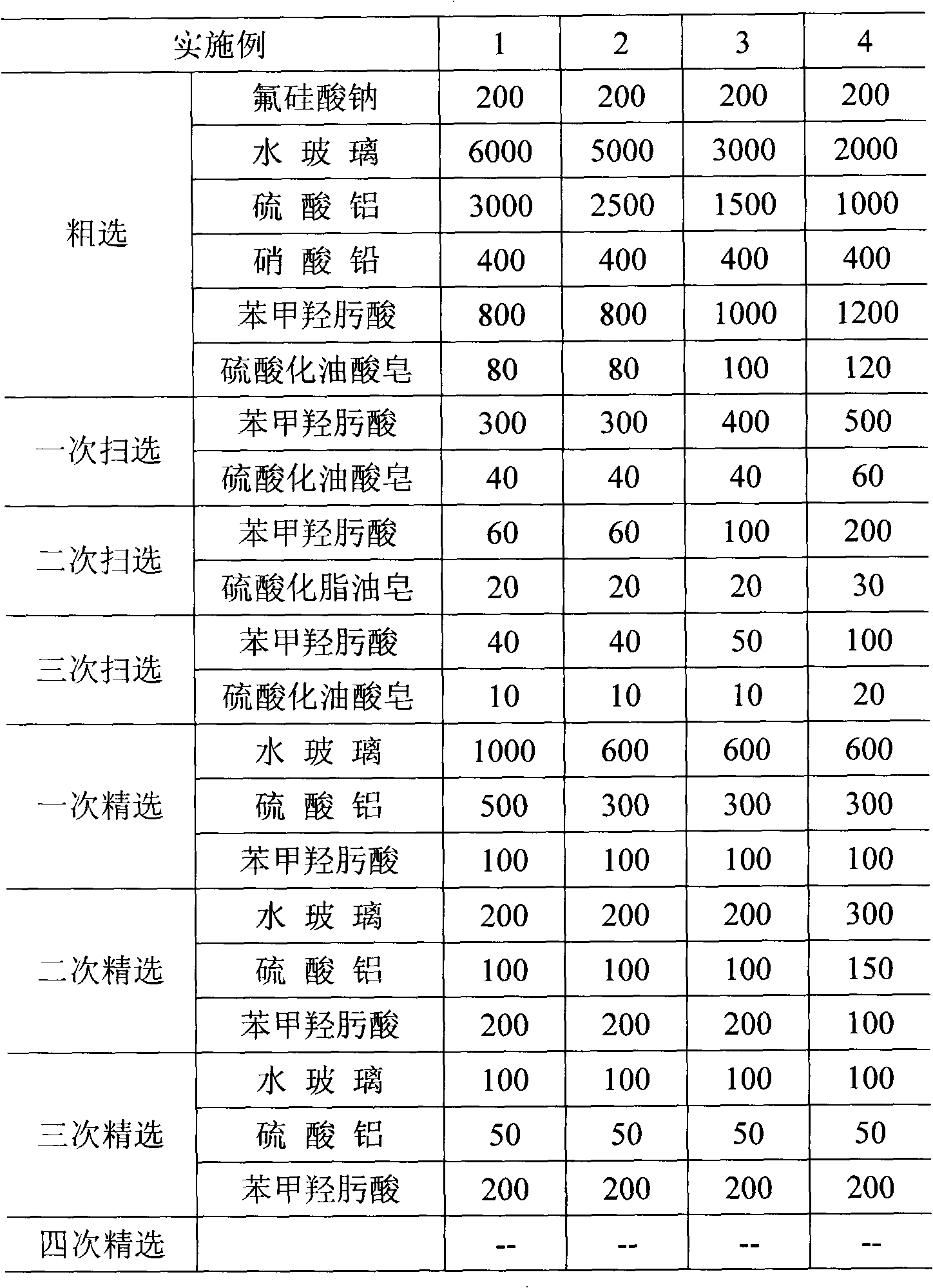

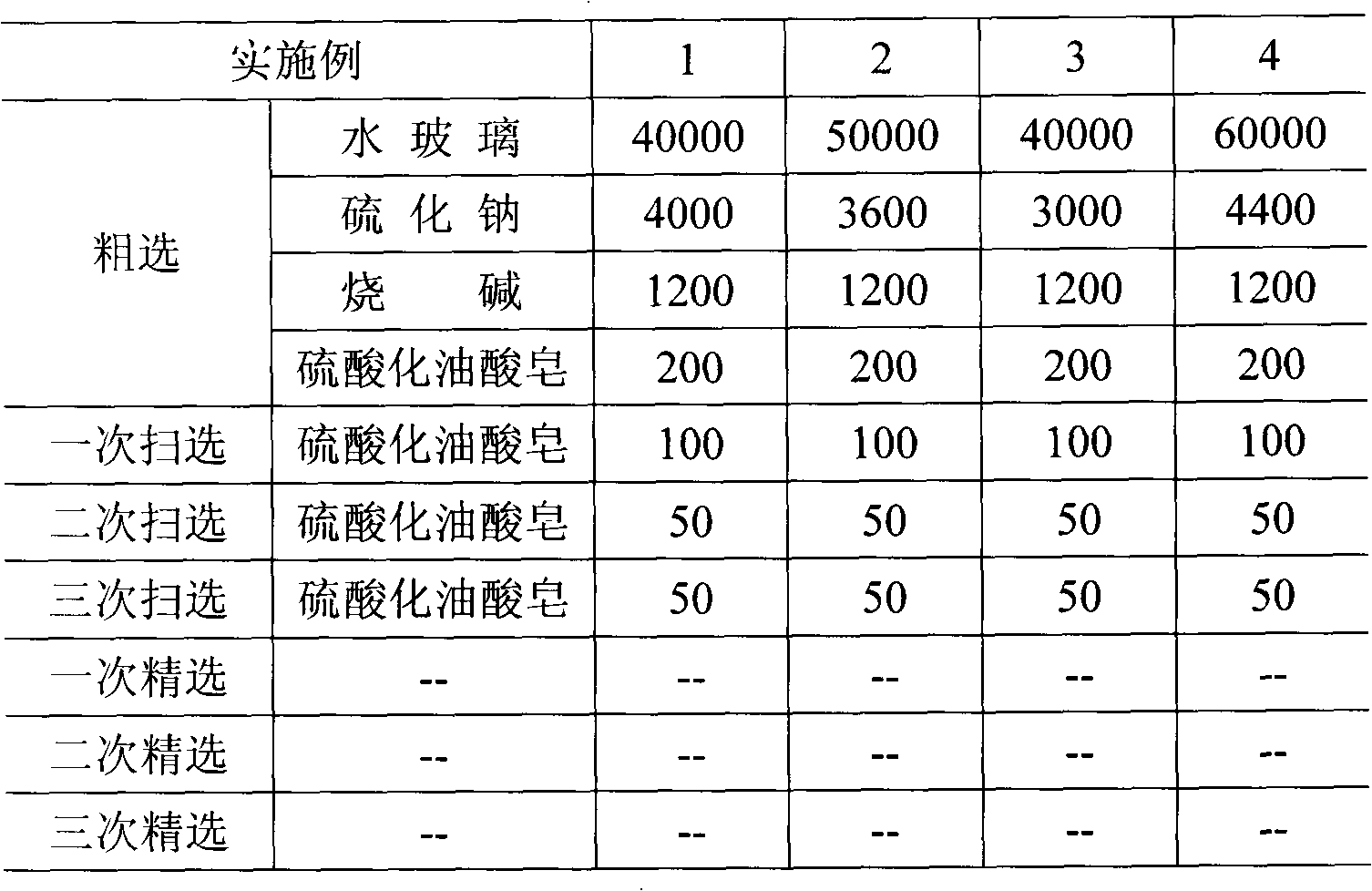

[0013] with WO 3 12.67%, Sn 0.2-0.5%, black and white tungsten ratio 1:9 black and white tungsten mixed flotation machine concentrate. Use a high gradient magnetic separator with a background magnetic field of 0.5 Tesla to separate wolframite from scheelite. After a rough separation, the output contains WO 3 10.65% wolframite coarse concentrate and containing WO 3 13.02% scheelite coarse concentrate. Black tungsten coarse concentrate is thickened to a weight concentration of 35%. Add sodium fluorosilicate, water glass, aluminum sulfate, lead nitrate, benzohydroxamic acid and sulfated oleic acid soap according to Table 1. After one roughing and three times of sweeping And four selections, the output contains WO 3 42.18% black tungsten concentrate and black tungsten concentrated tailings; thick scheelite coarse concentrate to a weight concentration of 65%, add sulfated fatty acid soap, sodium sulfide, caustic soda and water glass according to Table 2, and heat to 90-95 ℃, he...

Embodiment 2

[0015] with WO 3 24.43%, Sn 0.2-0.5%, black and white tungsten ratio 3.5:6.5 black and white tungsten mixed flotation rough concentrate. Use a high gradient magnetic separator with a background magnetic field of 0.8 Tesla to separate wolframite from scheelite. After a rough separation, the output contains WO 3 26.82% wolframite coarse concentrate and containing WO 3 23.42% scheelite coarse concentrate. Black tungsten coarse concentrate is dense to 35% in weight concentration, adding chemicals according to Table 1, after one roughing, three times of sweeping and four times of beneficiation, the output contains WO 3 65.87% black tungsten concentrate and black tungsten concentrated tailings; thick scheelite coarse concentrate to a weight concentration of 65%, add sulfated fatty acid soap, sodium sulfide, caustic soda and water glass according to Table 2, and heat to 90-95 ℃, heat preservation and stirring for 1 hour, after one roughing, three times of sweeping and three times ...

Embodiment 3

[0017] with WO 3 11.46%, Sn 0.2-0.5%, black and white tungsten ratio 5.3:4.7 black and white tungsten mixed flotation rough concentrate. Use a high gradient magnetic separator with a background magnetic field of 1 Tesla to separate wolframite from scheelite. After a rough separation, the output contains WO 3 15.08% wolframite coarse concentrate and containing WO 3 8.89% scheelite coarse concentrate. Black tungsten coarse concentrate is dense to 35% in weight concentration, adding chemicals according to Table 1, after one roughing, three times of sweeping and four times of beneficiation, the output contains WO 3 64.40% black tungsten concentrate and black tungsten concentrated tailings; thick scheelite coarse concentrate to a weight concentration of 65%, add sulfated fatty acid soap, sodium sulfide, caustic soda and water glass according to Table 2, and heat to 90-95 ℃, heat preservation and stirring for 1 hour, roughing once, sweeping three times and refining three times, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com