Combined reagent and flotation method for flotation of ultra-low grade rare earth ore and application of combined reagent

A combination of reagents and rare earth ore technology, applied in flotation, solid separation, etc., can solve the problems of low grade of rare earth concentrate, waste of rare earth resources, pollution of the environment, etc., achieve good flotation effect, save costs and resources, and use in pharmaceuticals less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

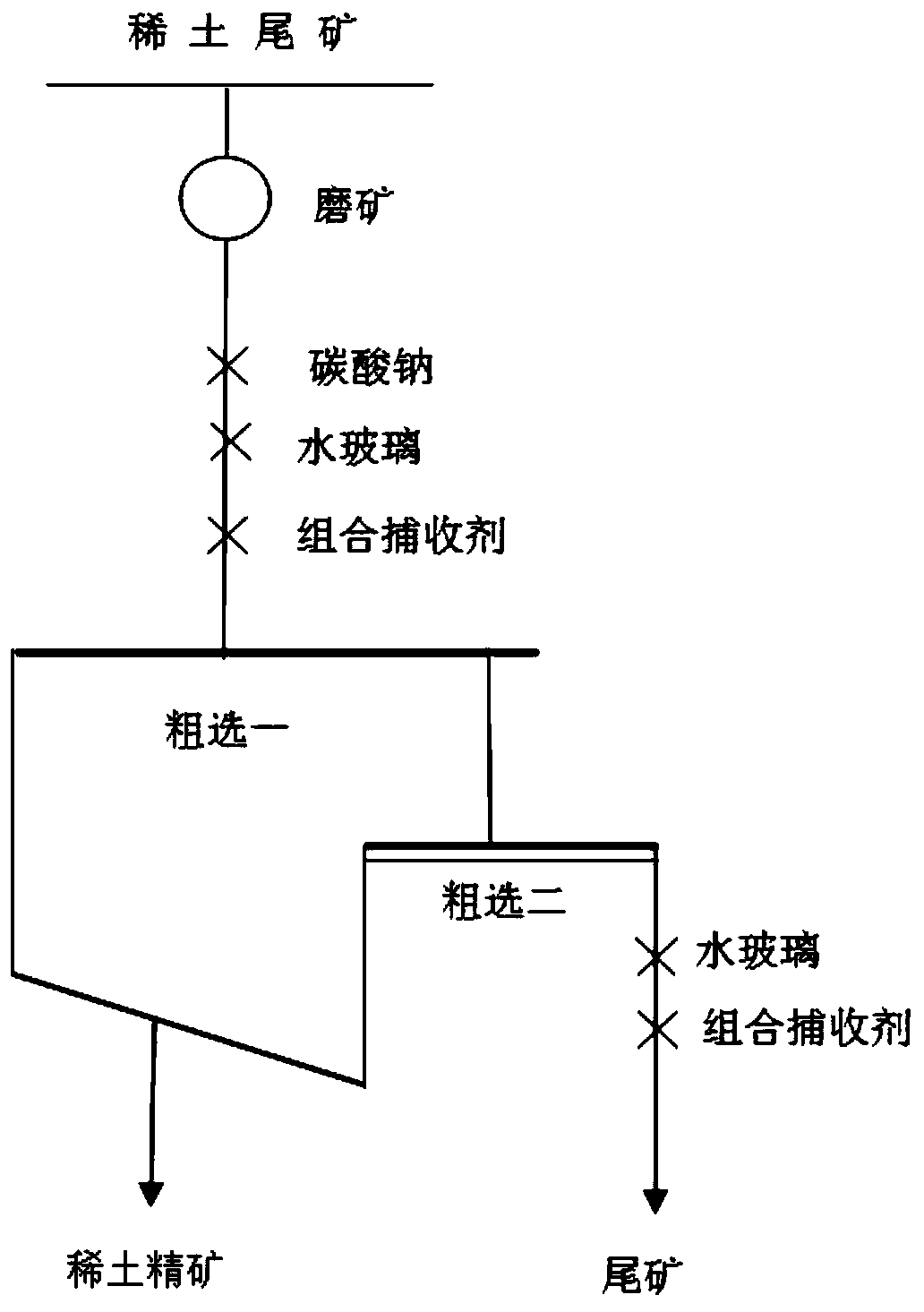

Method used

Image

Examples

Embodiment 1

[0028] Take 2000g of rare earth tailings, the rare earth REO grade is 0.157%, add 1000ml of water for wet grinding, and grind for 4 minutes, so that the grinding fineness is -0.074mm and accounts for 68%. First, add 750g / t sodium carbonate to the pulp to adjust the pH value of the pulp to 9.01, add 500g / t inhibitor water glass to the pulp, and stir for 3 minutes. Add 300g / t and 100g / t benzohydroxamic acid and octyl hydroxamic acid respectively in sequence, stir for 6 minutes, and carry out rough flotation for 5 minutes. For its rare earth roughing tailings, first add 200g / t of water glass, stir for 3 minutes, then add 100g / t and 50g / t of benzohydroxamic acid and octylhydroxamic acid in turn, stir for 5 minutes, and then carry out Flotation for 4 minutes. The final rare earth REO grade was raised from 0.157% to 18.76%, and the enrichment ratio was as high as 120.

Embodiment 2

[0034] Take 2000g of rare earth tailings, the rare earth REO grade is 0.157%, and add 1000ml of water for wet grinding, so that the grinding fineness is -0.074mm, accounting for 68%. First, add 750g / t sodium carbonate to the pulp to adjust the pH value of the pulp to 9.6, add 500g / t water glass to the pulp, stir for 3 minutes, then add 350g / t and 150g / t benzohydroxamic acid and octyl in turn hydroxamic acid, stirred for 6 minutes, and flotation was carried out for 5 minutes. For its rare earth roughing tailings, first add 200g / t of water glass, stir for 3 minutes, then add 200g / t and 80g / t of benzohydroxamic acid and octylhydroxamic acid respectively, stir for 5 minutes, and then carry out Flotation for 4 minutes. The final rare earth REO grade was raised from 0.163% to 19.59%, and the effect was ideal.

Embodiment 3

[0040] Take 2000g of rare earth tailings, the rare earth REO grade is 0.157%, add 1000ml of water for wet grinding, and grind for 4 minutes, so that the grinding fineness is -0.074mm and accounts for 78.34%. First, add 750g / t sodium carbonate to the pulp to adjust the pH of the pulp to 9.01, add 500g / t water glass to the pulp, stir for 3 minutes, then add 300g / t and 100g / t benzyl hydroxamic acid and octyl respectively hydroxamic acid, stirred for 6 minutes, and flotation was carried out for 5 minutes. For its rare earth roughing tailings, first add 200g / t of water glass, stir for 3 minutes, then add 100g / t and 50g / t of benzohydroxamic acid and octylhydroxamic acid in turn, stir for 5 minutes, and then carry out Flotation for 4 minutes. The final rare earth REO grade was raised from 0.157% to 20.34%, and the enrichment ratio was as high as 120.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com