Benefication method for concentrating fine tungsten ore in tailings by warming scheelite

A beneficiation method and fine-grained technology, which is applied in the field of reclaiming fine-grained tungsten ore, can solve the problems of no sorting, poor sorting effect, unfavorable flotation of black and white tungsten minerals, etc., and achieve simple process flow and beneficiation The effect of stable process and low chemical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

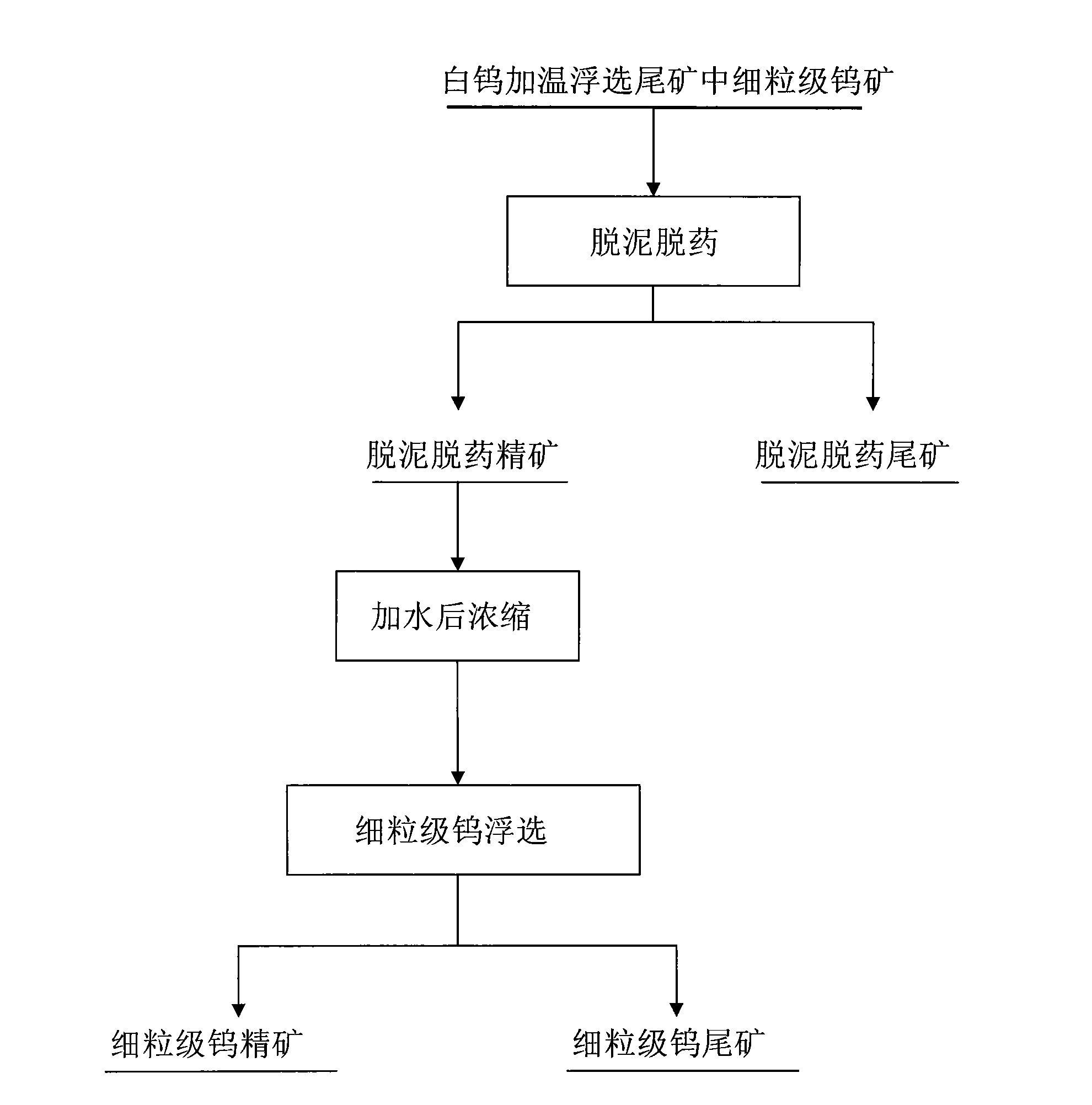

Method used

Image

Examples

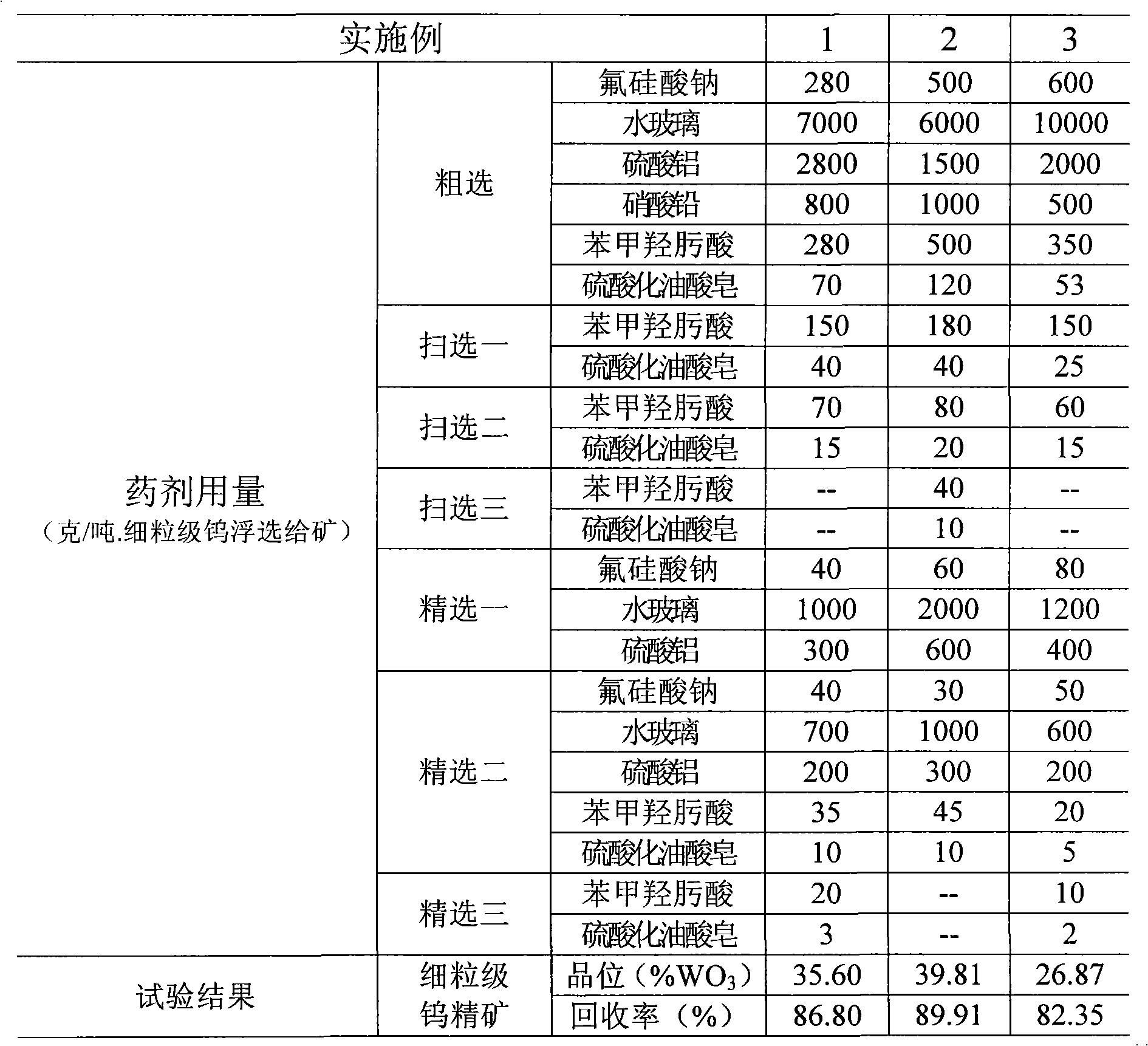

Embodiment 1

[0013] Fine-grained tungsten ore containing WO 3 4.01%, less than 30 micron particle size WO 3 The metal occupancy rate is 65%, and the ratio of black and white tungsten is 4:6. After the tailings re-selected by the shaker are settled by the slurry, the upper layer of the slurry (mud and some chemicals) is removed, and the deslimed and drug-removed concentrate is concentrated to a slurry concentration of 26% and a pH value of about 8.5 after being added to the fine ore. For particle size tungsten flotation, add regulator sodium fluorosilicate, water glass, aluminum sulfate and lead nitrate according to the reagent system in Table 1, stir for 8 minutes, add collectors benzhydroxamic acid and sulfated oleic acid soap and stir for 5 minutes Minutes later, carry out fine-grained tungsten ore flotation, after 1 time of roughing, 3 times of beneficiation, and 2 times of scavenging, the WO-containing 3 35.60% fine-grained tungsten concentrate, the recovery rate is 86.80%.

Embodiment 2

[0015] Fine-grained tungsten ore containing WO 3 5.10%, less than 30 micron particle size WO 3 The metal occupancy rate is 60%, and the ratio of black and white tungsten is 9:1. After the tailings re-selected by the shaker are settled by the slurry, the upper layer of the slurry (mud and some chemicals) is removed, and the deslimed and drug-removed concentrate is concentrated to a slurry concentration of 44% and a pH value of about 8.5 after adding water to the fine ore. For particle size tungsten flotation, add regulator sodium fluorosilicate, water glass, aluminum sulfate and lead nitrate according to the reagent system in Table 1, stir for 5 minutes, add collector benzyl hydroxamic acid and sulfated oleic acid soap and stir for 6 Minutes later, fine-grained tungsten ore flotation was carried out, and after 1 roughing, 2 refining, and 3 sweeping, the WO-containing 3 39.81% fine-grained tungsten concentrate, the recovery rate is 89.91%.

Embodiment 3

[0017] Fine-grained tungsten ore containing WO 3 0.95%, less than 30 micron particle size WO 3 The metal occupancy rate is 70%, and the ratio of black and white tungsten is 1:9. After the tailings re-selected by the shaker are settled by the slurry, the upper layer of the slurry (mud and some chemicals) is removed, and the deslimed and drug-free concentrate is added with water and then concentrated to a slurry concentration of 30% and a pH value of the slurry of about 8.5. For particle size tungsten flotation, add regulator sodium fluorosilicate, water glass, aluminum sulfate and lead nitrate according to the reagent system in Table 1, stir for 10 minutes, add collectors benzohydroxamic acid and sulfated oleic acid soap and stir for 4 Minutes later, the flotation of fine-grained tungsten ore was carried out, and after 1 roughing, 4 times of concentration, and 2 times of sweeping, the WO-containing 3 26.87% fine-grained tungsten concentrate, the recovery rate is 82.35%.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com