Stone-like coal navajoite physical mineral dressing method

A mineral processing method, stone coal vanadium technology, applied in flotation, solid separation, etc., to achieve the effect of solving the pollution of three wastes, reducing the amount of raw materials and tailings, and reducing the pollution of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

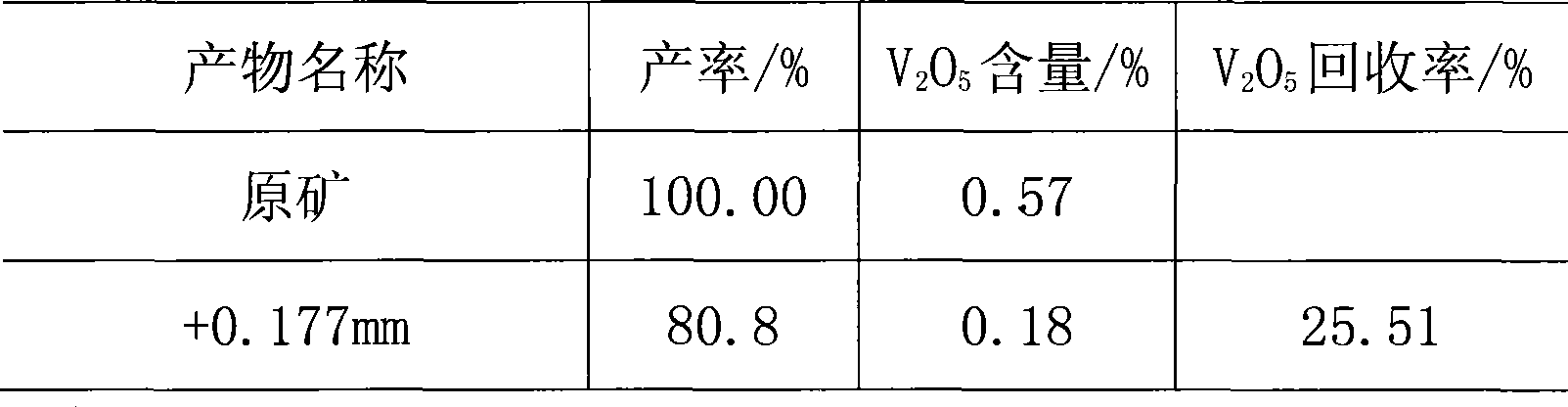

[0023] A stone coal vanadium mine in Xinjiang, the appearance is coarse-grained with fine powder, dark brown, average V 2 o 5 Content 0.57%, process 3000 grams of raw ore according to the method of the present invention, after adopting selective crushing, use wet sieving to separate out +0.85mm coarse-grained grade, productive rate 80.8%, V 2 o 5 Content 0.18; use wet sieving to classify -0.023mm, yield 8.5%, V 2 o 5 Content 3.26%; intermediate grade (0.023mm ~ 0.85mm) yield 10.70%, V 2 o 5 The content is 1.38%. After selective grinding, it is flotation in 11 aeration stirring flotation machines. Sodium hexametaphosphate and water glass are used as regulators, each dosage is 600g / t, and sodium lauryl sulfate is used as collector. The dosage is 500g / t, pine alcohol oil is used as foaming agent, the dosage is 180g / t, one roughing, four sweeping and two beneficiation processes are adopted to obtain the flotation foam concentrate V 2 o 5 3.34%, flotation tailings V 2 o 5 ...

example 2

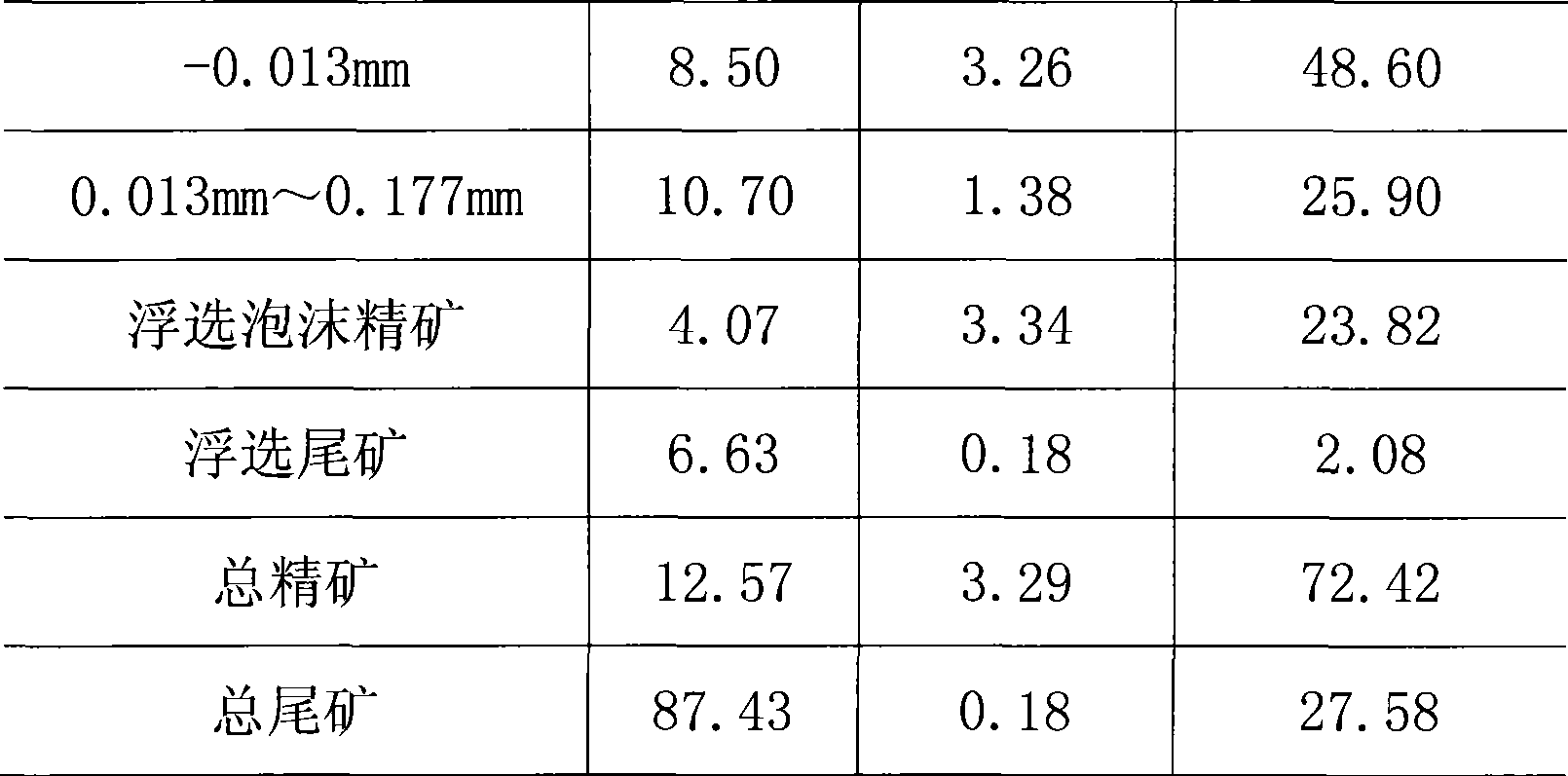

[0027] A stone coal vanadium mine in Chongqing, the appearance of coarse grains mixed with fine powder, light brown, average V 2 o 5 Content 1.14%, process 2000 grams of raw ore according to the method of the present invention, after adopting selective crushing, use wet sieving to separate out +0.85mm coarse-grained grade, productive rate 57.4%, V 2 o 5 Content 0.23%; use wet hydraulic fractionation to separate -0.01mm, yield 16.84%, V 2 o 5 Content 4.12%; intermediate grade (0.01mm ~ 0.85mm) yield 5.76%, V 2 o 5 Content 1.22%, flotation in 11 inflatable agitation flotation machine after selective grinding, use sodium carbonate as regulator, dosage 1200g / t, use benzyl hydroxy acid as collector, dosage 600g / t, use butyl Ether alcohol is used as a foaming agent, the dosage is 100g / t, and one roughing, four sweeping and two beneficiation processes are adopted to obtain the flotation foam concentrate V 2 o 5 3.34%, flotation tailings V 2 o 5 Content 0.28%. (see the table...

example 3

[0031] A stone coal vanadium mine in Xinjiang, the appearance of coarse grains and fine powder, light brown, average V 2 o 5Content 0.70%, process 2000 grams of raw ore according to the method of the present invention, after selective crushing, use wet sieving to separate out +0.85mm coarse grain grade, yield 66.85%, then use wet classification to separate out -0.037mm, yield 10.83%, and then for the intermediate grade (0.037mm~0.85mm) with a yield of 23.12%, flotation in a 1.5L mechanically stirred flotation machine, using sodium hexametaphosphate as a regulator, the dosage is 1200g / t, and ten Octamine is used as a collector with an amount of 1500g / t, and isooctyl alcohol is used as a foaming agent with an amount of 180g / t. One roughing and four times of sweeping and one beneficiation process are adopted to obtain flotation foam concentrate V 2 o 5 Content 3.24%, flotation tailings V 2 o 5 Content 0.42%. (see the table below)

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com