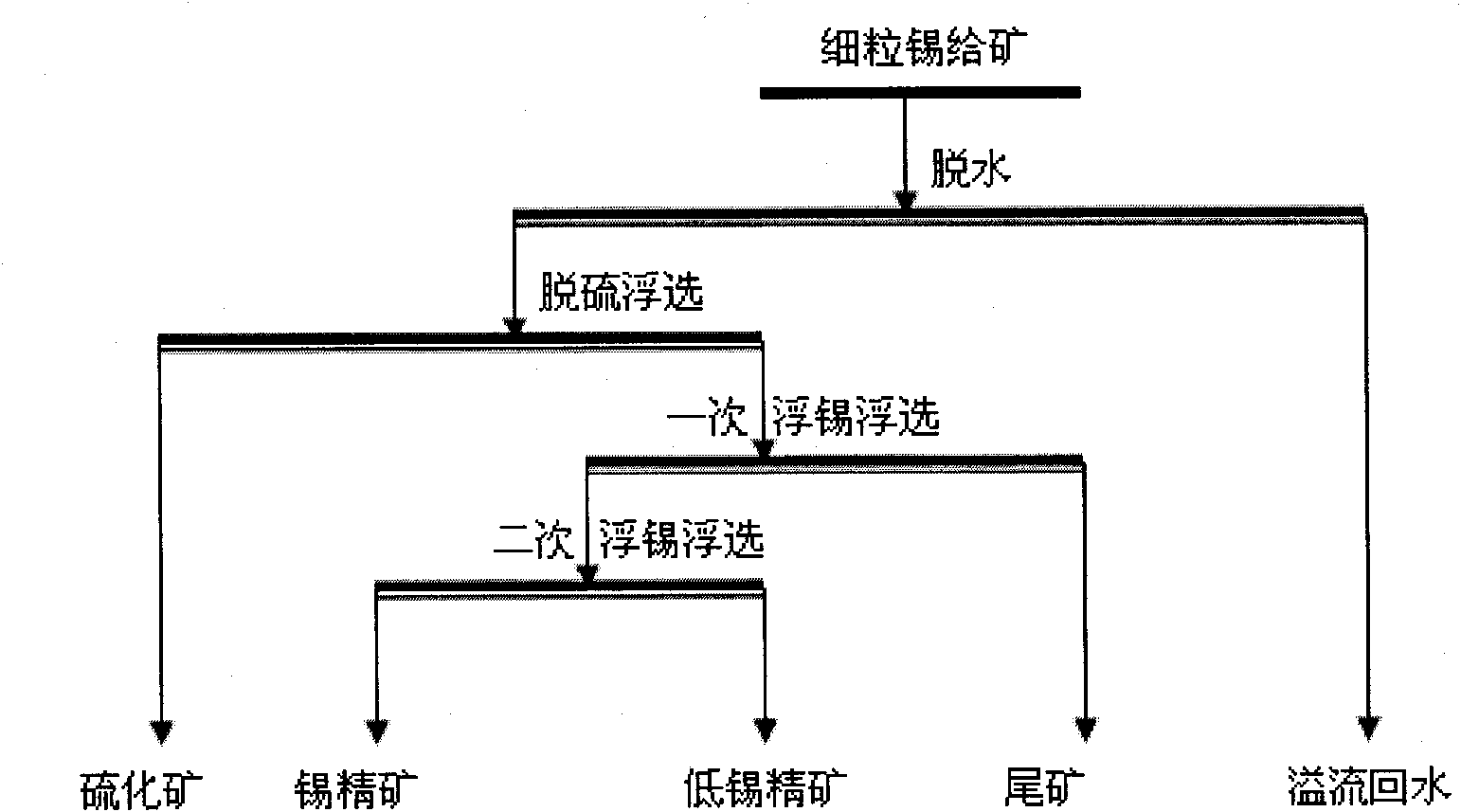

Combined mineral dressing technology of fine grain and micro grain cassiterite

A technology of fine particles and cassiterite, applied in flotation, chemical instruments and methods, solid separation, etc., can solve the problems of high loss rate, affecting the recovery rate of cassiterite, etc., and achieve good economic and social benefits and beneficiation recovery rate. Low cost, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

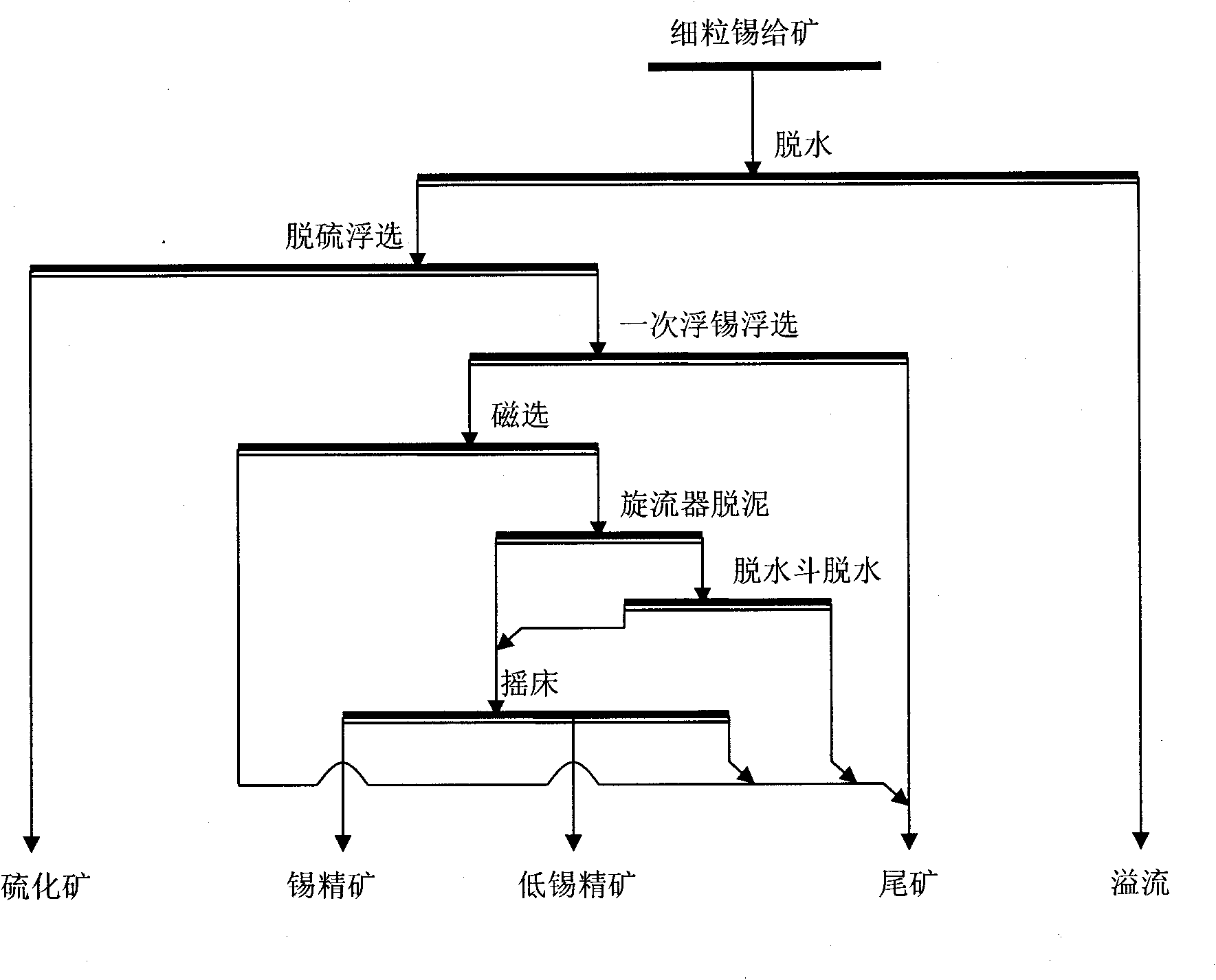

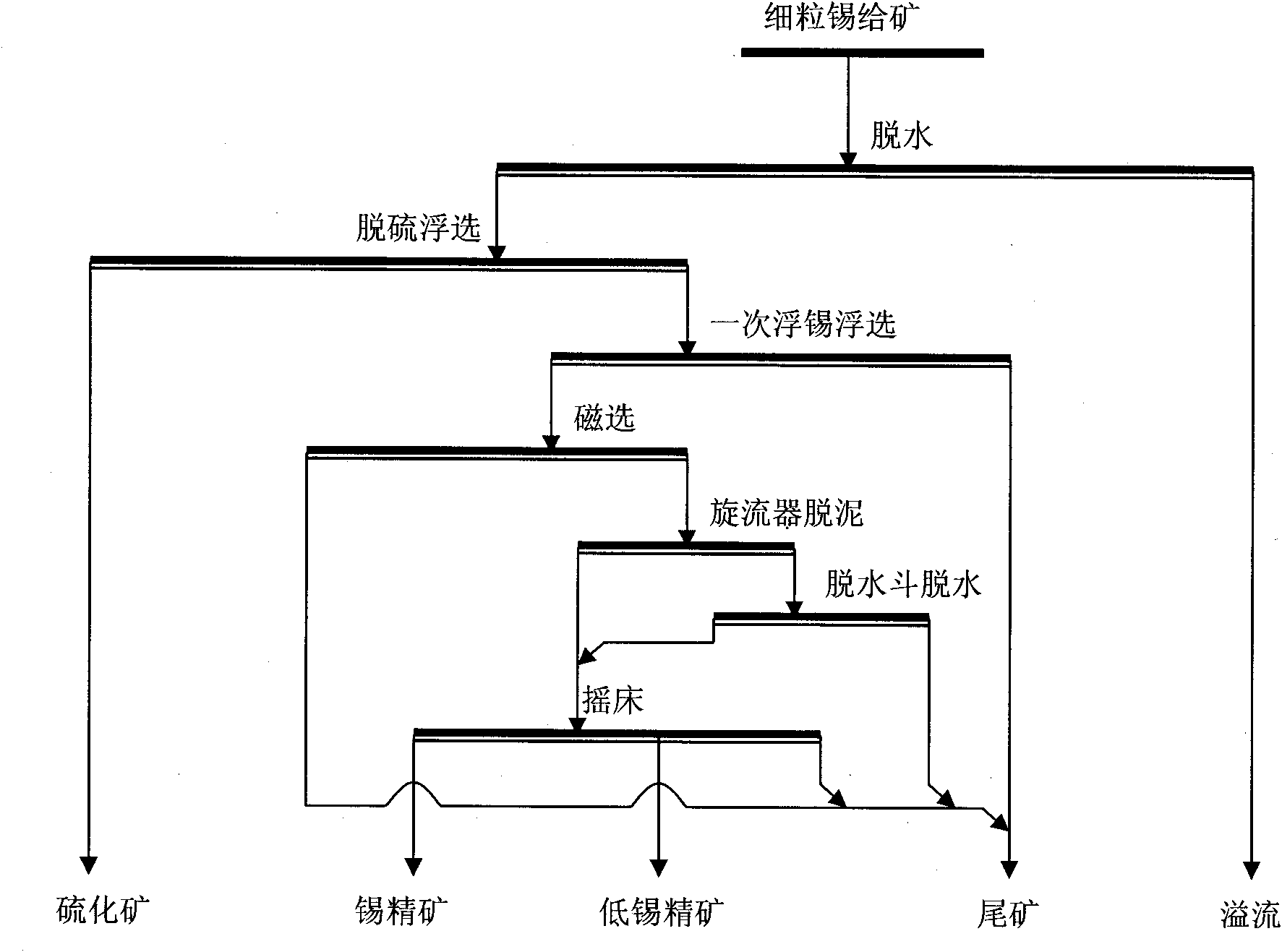

Method used

Image

Examples

Embodiment 1

[0052] After the fine-grained and fine-grained ore pulp less than 37 microns is concentrated and precipitated by a Φ30-meter thickener, the overflow and overflow are treated separately for production water supply, and the sulfide ore is removed by a flotation machine for sand settling to realize the separation of sulfide ore and oxidized ore. . The weight of desulfurization water is 0.8t / t to feed the ore, and the weight of activator copper sulfate is 0.3g / t; the weight of collector isoamyl xanthate is 0.2g / t; ; Normal temperature flotation, the sulfide ore foam produced by flotation is treated separately, and the flotation tailings enter the tin flotation operation. The weight of water for tin floating operation is 1.4t / t to ore; the weight of styrene phosphoric acid is 0.3g / t; the weight of collector 2-hydroxy-3-benzohydroxamic acid is 0.2g / t and water The weight of salicylic hydroxamic acid is 0.2g / t; the weight of soda ash as regulator is 0.3g / t; the weight of pine alcoho...

Embodiment 2

[0054] After the fine-grained and fine-grained ore pulp less than 37 microns is concentrated and precipitated by a Φ30-meter thickener, the overflow and overflow are treated separately for production water supply, and the sulfide ore is removed by a flotation machine for sand settling to realize the separation of sulfide ore and oxidized ore. . The weight of water for desulfurization is 1.1t / t to feed the ore, and the weight of activator copper sulfate is 0.35g / t; the weight of collector isoamyl xanthate is 0.3g / t; ; Normal temperature flotation, the sulfide ore foam produced by flotation is treated separately, and the flotation tailings enter the tin flotation operation. The weight of water for tin floating operation is 1.0t / t to feed ore; the weight of inhibitor aryl phosphoric acid is 0.15g / t and the weight of octylphenyl polyoxyethylene ether is 0.1g / t; the collector is alkyl sulfonated The weight of succinamic acid salt is 0.3g / t; the weight of soda ash as a regulator is...

Embodiment 3

[0056] After the fine-grained and fine-grained ore pulp less than 37 microns is concentrated and precipitated by a Φ30-meter thickener, the overflow and overflow are treated separately for production water supply, and the sulfide ore is removed by a flotation machine for sand settling to realize the separation of sulfide ore and oxidized ore. . The weight of desulfurization water is 1.5t / t to feed the ore, and the weight of activator copper sulfate is 0.4g / t; the weight of collector isoamyl xanthate is 0.4g / t; ; Normal temperature flotation, the sulfide ore foam produced by flotation is treated separately, and the flotation tailings enter the tin flotation operation. The weight of water for tin floating operation is 0.7t / t for ore; the weight of inhibitor alkyl phosphoric acid is 0.1g / t and the weight of aryl phosphoric acid is 0.1g / t; the collector 2-hydroxy-3-benzyl hydroxy The weight of oxime acid is 0.2g / t; the weight of soda ash as regulator is 0.15g / t; the weight of pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com