Ore dressing method of vanadium titanium magnetite

A technology of vanadium-titanium magnetite and ore dressing method, which is applied in the field of physical method ore dressing, can solve the problems of high cost and complicated process, and achieve the effect of reducing the cost of magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

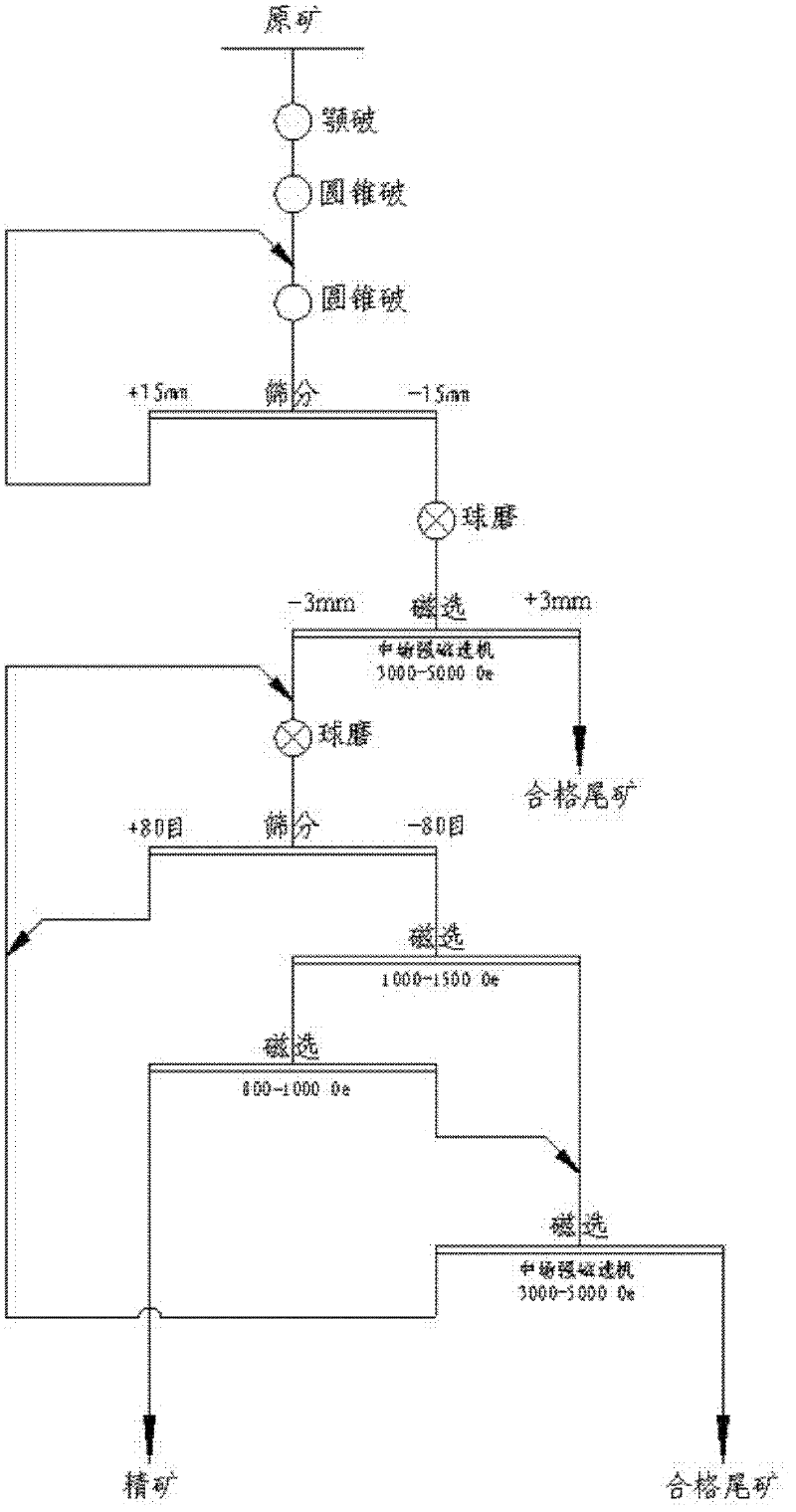

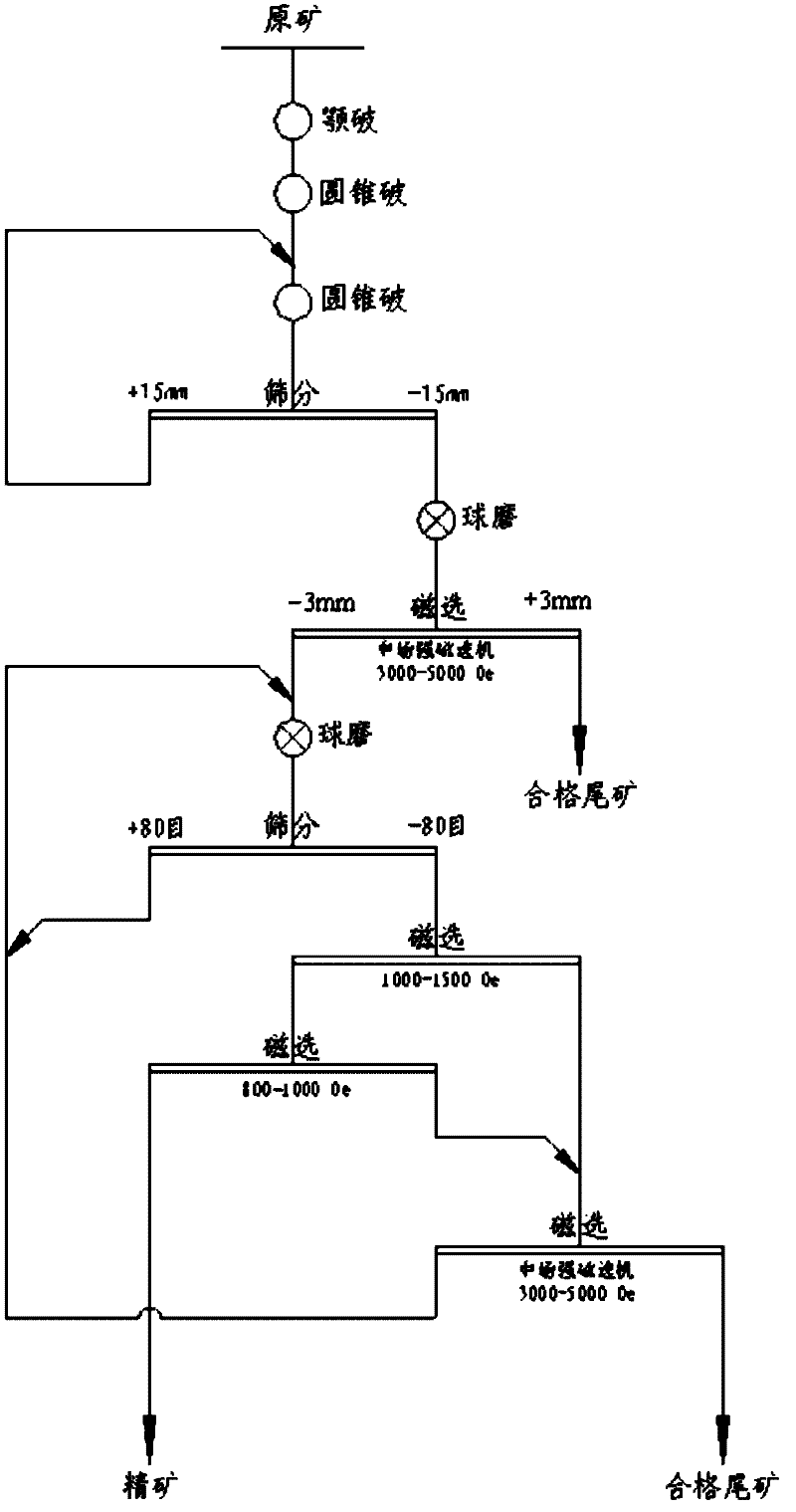

Image

Examples

Embodiment

[0023] Take TFe as 24.54%, TiO 2 100 kg of vanadium-titanium magnetite with a content of 9.5%, the ore is crushed and screened, and the final crushed ore particle size is ≤15mm; the crushed ore enters a ball mill and is finely ground to a particle size of ≤3mm, using a magnetic separator with a field strength of 4000Oe Carry out magnetic separation to obtain 85.28 kg of coarse concentrate and tailings; after magnetic separation, the coarse concentrate is ball-milled to -80 mesh, magnetically separated by a magnetic separator with a field strength of 1200Oe, and then separated by a magnetic separator of 1000Oe ; Finally, 34.5 kg of iron ore concentrate with a TFe of 59.25% is obtained; the tailings enter the next step of titanium beneficiation and utilization.

[0024] Adopt ore dressing method of the present invention, select field strength 3000-5000Oe for use in a step, select field strength 1000-1500Oe for use in b step, select field strength 800-1000Oe for use in c step; Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com