Ore dressing method for low-grade rare earth ore

A beneficiation method and rare earth ore technology, applied in chemical instruments and methods, wet separation, solid separation, etc., to achieve the effect of reducing the amount of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

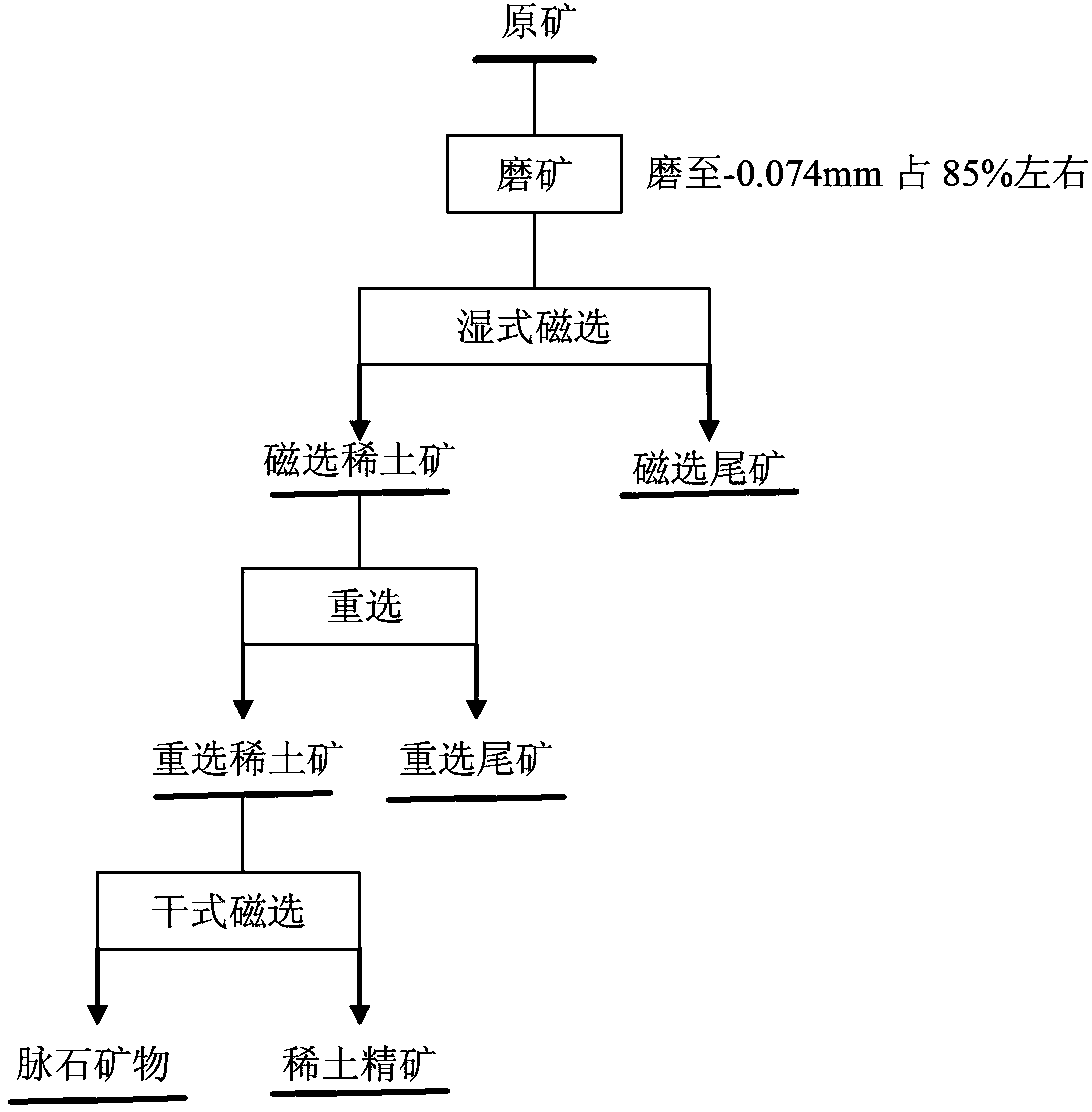

Method used

Image

Examples

Embodiment 1

[0013] The rare earth content of a rare earth mine in Xinjiang is 0.099%; Grinding: the raw ore is crushed and ground to -0.074mm, accounting for 84.87%; wet magnetic separation: the magnetic field strength is 800MT, and the magnetic separation tailings with a yield of 95.36% are thrown away; gravity separation: Magnetic separation rare earth ore undergoes re-election on a shaking table, throwing away gravity-separated tailings with a yield of 4.50%; dry magnetic separation: re-separated rare-earth ore undergoes dry magnetic separation with a magnetic field strength of 450MT and a removal rate of 0.04 % of gangue minerals to obtain rare earth concentrates.

[0014] The results of Example 1 are shown in Table 1.

[0015] The result of table 1 embodiment 1

[0016] name Yield(%) Rare earth grade (%) Rare earth recovery rate (%) Rare earth concentrate 0.10 50.59 51.00 gangue minerals 0.04 1.42 0.57 Gravity tailings 4.50 0.22 9.98 Magn...

Embodiment 2

[0018] The rare earth content of a rare earth mine in Jiangxi is 0.081%; Grinding: The original ore is crushed and ground to -0.074mm, accounting for 85.33%; Wet magnetic separation: The magnetic field strength is 1000MT, and the magnetic separation tailings with a yield of 92.89% are discarded; Gravity election: Magnetic separation rare earth ore undergoes re-election on a shaking table, throwing away the gravity-separated tailings with a yield of 6.97%; dry magnetic separation: gravity-separated rare-earth ore undergoes dry magnetic separation with a magnetic field strength of 500MT, and the removal rate is 0.053 % of gangue minerals to obtain rare earth concentrates.

[0019] The results of Example 2 are shown in Table 2.

[0020] The result of table 2 embodiment 2

[0021] name Yield(%) Rare earth grade (%) Rare earth recovery rate (%) Rare earth concentrate 0.087 50.24 50.58 gangue minerals 0.053 1.26 0.77 Gravity tailings 6.97 0.19...

Embodiment 3

[0023] The rare earth content of a rare earth mine in Fujian is 0.079%; Grinding: The raw ore is crushed and ground to -0.074mm, accounting for 84.61%; Wet magnetic separation: The magnetic field strength is 950MT, and the magnetic separation tailings with a yield of 92.31% are thrown away; Gravity separation: Magnetic separation rare earth ore undergoes re-election on a shaking table, throwing away the gravity-separated tailings with a yield of 7.55%; dry magnetic separation: gravity-separated rare-earth ore undergoes dry magnetic separation with a magnetic field strength of 400MT, and the removal rate is 0.069 % of gangue minerals to obtain rare earth concentrates.

[0024] The results of Example 3 are shown in Table 3.

[0025] The result of table 3 embodiment 3

[0026] name Yield(%) Rare earth grade (%) Rare earth recovery rate (%) Rare earth concentrate 0.071 51.37 46.09 gangue minerals 0.069 1.14 0.99 Gravity tailings 7.55 0.2 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com