Ore dressing method of low-grade scheelite

A beneficiation method and scheelite technology, applied in flotation, solid separation and other directions, can solve the problems of toxicity, high cost of lead nitrate, benzhydroxamic acid, and high cost of sulfated oleic acid soap, and can reduce the dosage and cost, the effect of reducing the amount of flotation beneficiation and reducing the cost of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

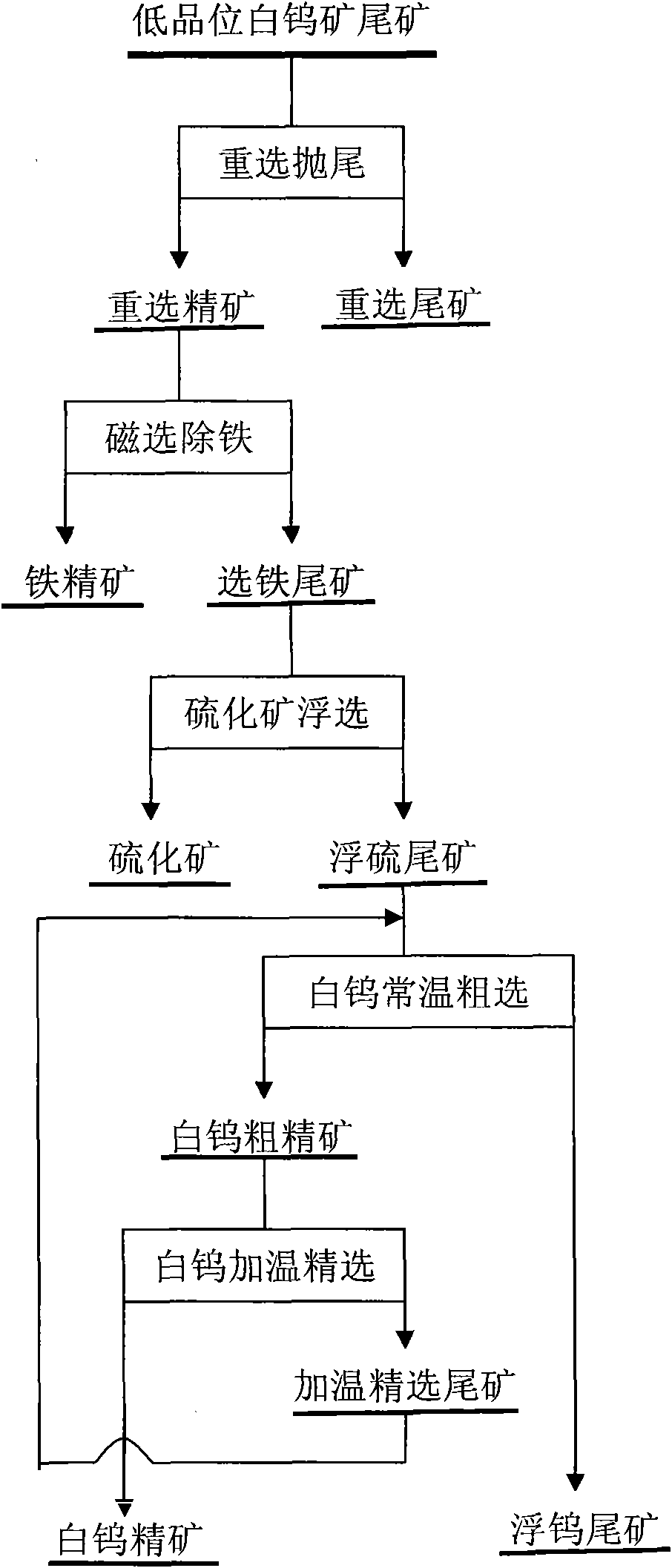

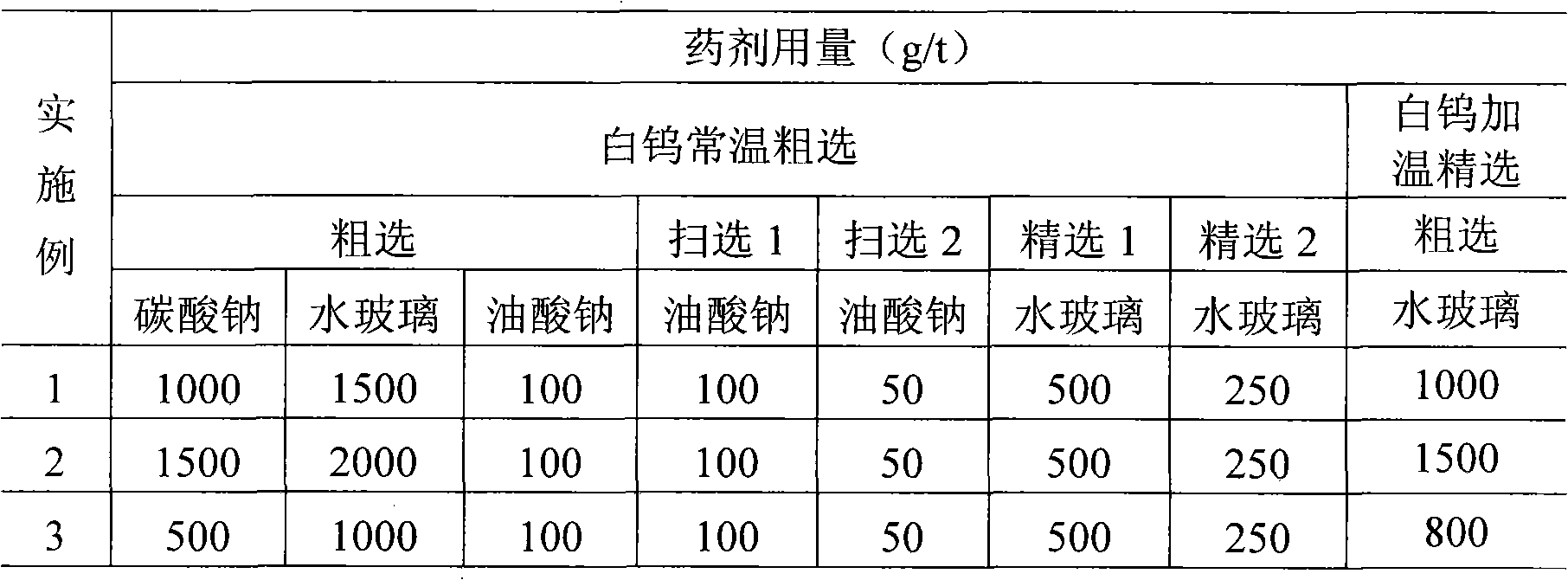

[0019] Low-grade flotation tailings from a molybdenum-copper mine in Guangdong (WO 3 0.063%) of scheelite, particle size composition -0.074mm accounts for 75%, it is suitable for gravity separation to throw tailings, gravity separation of scheelite coarse concentrate to remove magnetite and sulfide minerals, and then roughing scheelite at room temperature and scheelite Warming selection.

[0020] Gravity separation and tailings discarding: the spiral concentrator is used as the material gravity separation equipment of -1.0mm particle size, and 64.69% of the tailings are discarded by gravity separation, and the grade of gravity concentration is increased to WO 3 0.14%, recovery rate 79.26%.

[0021] Magnetic separation iron removal: iron removal under the magnetic induction intensity of 2000Gs.

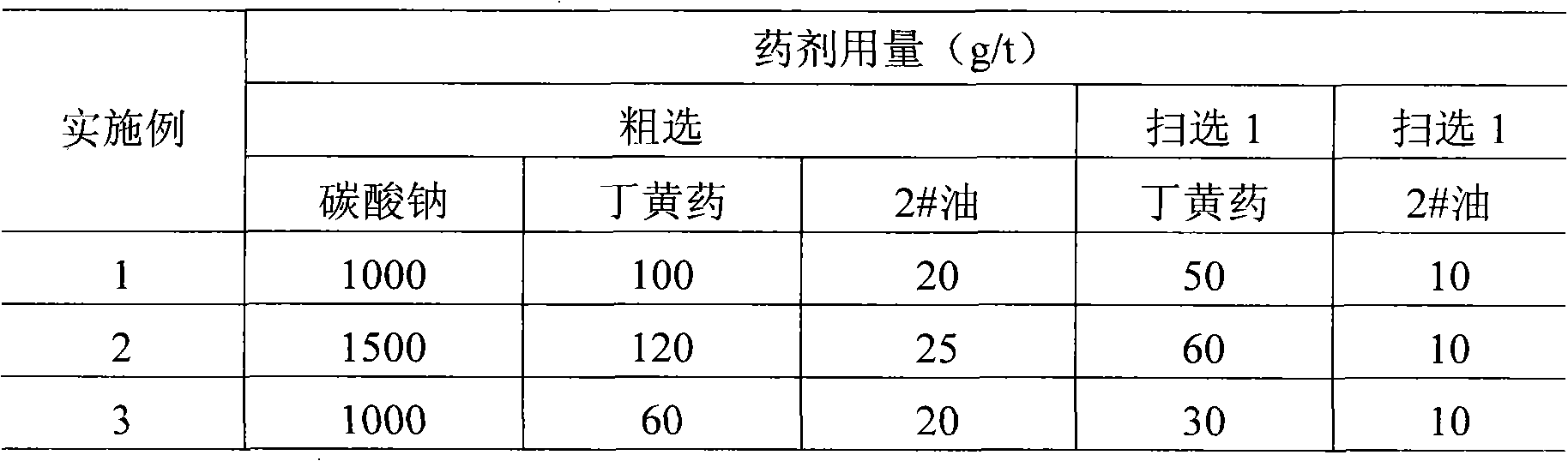

[0022] Sulfide ore flotation: According to the amount of chemicals listed in Table 1, carry out sulfide ore flotation on iron ore tailings to obtain sulfide ore flotation concentra...

Embodiment 2

[0028] Medium and low-grade tailings of a molybdenum-copper-tungsten mine in Yunnan (WO 3 0.092%) of scheelite resources, the main tungsten mineral is scheelite. A very small amount of pyrite, chalcopyrite, galena and other sulfide minerals. Other gangue minerals are mainly muscovite and calcite. Tailings particle size composition -0.074mm accounted for 70%. It is suitable to use gravity separation to throw tailings, gravity separation of scheelite rough concentrate to remove magnetite and sulfide minerals, and then carry out scheelite normal temperature rough separation and scheelite heating and concentration.

[0029] Gravity separation and tailings throwing: use spiral concentrator as -1.0mm particle size material gravity separation equipment, gravity separation throws away 68.54% of tailings, and the grade of gravity separation concentrate is raised to WO 3 0.25%, the recovery rate is 84.50%.

[0030] Magnetic separation iron removal: iron removal under the magnetic ...

Embodiment 3

[0037] Medium and low-grade tailings of a skarn-type plate-shaped copper, bismuth, molybdenum, sulfur, and tungsten mine in Gansu (WO 3 0.14%) of scheelite resources, scheelite is the main recovery of useful minerals in tailings. Tailings particle size composition -0.074mm accounted for 80%. It is suitable to use gravity separation to throw tailings, gravity separation of scheelite rough concentrate to remove magnetite and sulfide minerals, and then carry out scheelite normal temperature rough separation and scheelite heating and concentration.

[0038] Gravity separation and tailings discarding: the spiral concentrator is used as the material gravity separation equipment of -1.0mm particle size, and 60.78% of the tailings are discarded by gravity separation, and the grade of gravity concentration is increased to WO 3 0.27%, recovery rate 71.93%.

[0039] Magnetic separation iron removal: iron removal under the magnetic induction intensity of 1000Gs.

[0040] Sulfide ore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com