Magnetic ore dressing method

A beneficiation method and ore technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as difficulty in obtaining high-efficiency enrichment of ilmenite and complicated process flow, so as to reduce energy consumption and simplify the process flow , The effect of reducing the process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

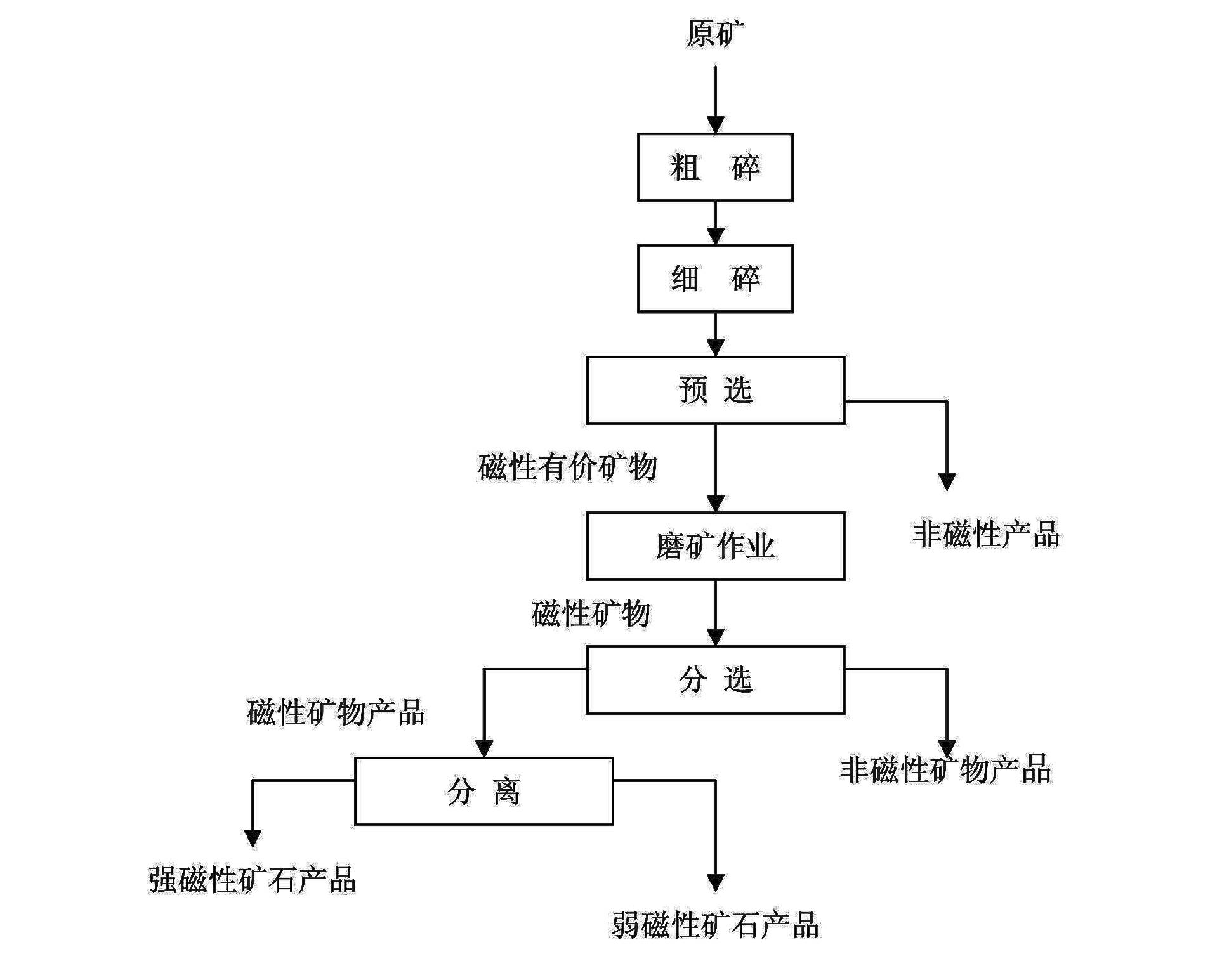

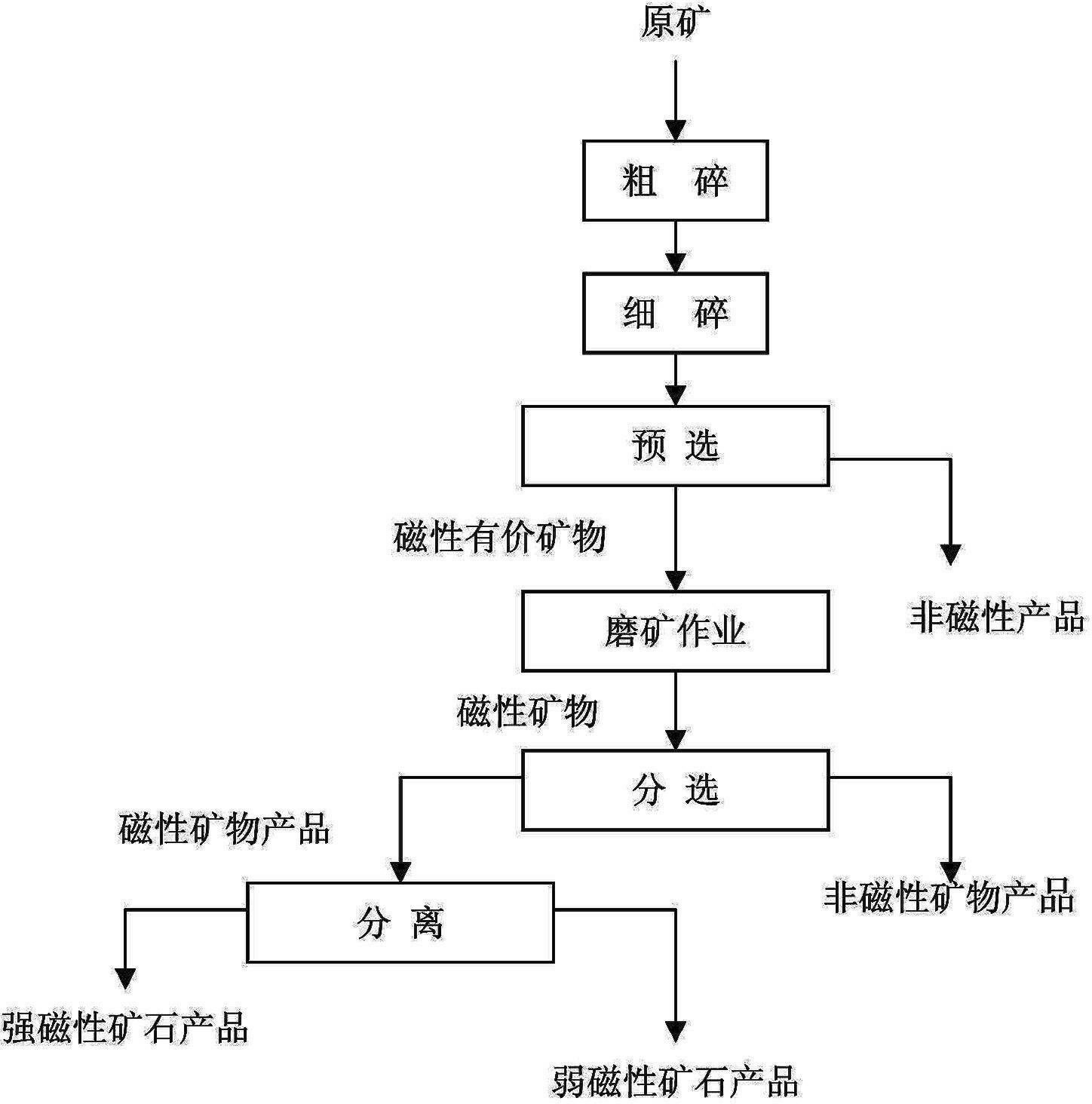

[0027] a kind of like figure 1 The beneficiation method of the magnetic ore of the present invention shown may further comprise the steps:

[0028] (1) Pretreatment: firstly, the raw magnetic ores containing different ratio magnetic susceptibility coefficients (such as the iron ore type mixed with magnetite and hematite, or the type of vanadium-titanium magnetite and ilmenite) are subjected to coarse crushing in sequence And fine crushing operations, so that the magnetic minerals and non-magnetic minerals can achieve partial monomer dissociation, ready to enter the pre-selection;

[0029] (2) pre-selection: select a ZCLA pre-selector (this embodiment adopts the magnetic separator disclosed in No. CN101648162A Chinese patent document), this ZCLA pre-selector has a magnetic separation area composed of different magnetic circuits by various perma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com