Ore-dressing method for low-grade bauxite

A technology of low-grade bauxite and beneficiation methods, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of water system not being able to form a system, incomplete ore dissociation, difficult equipment maintenance, etc. Achieve the effect of reducing production costs, easy to meet conditions, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

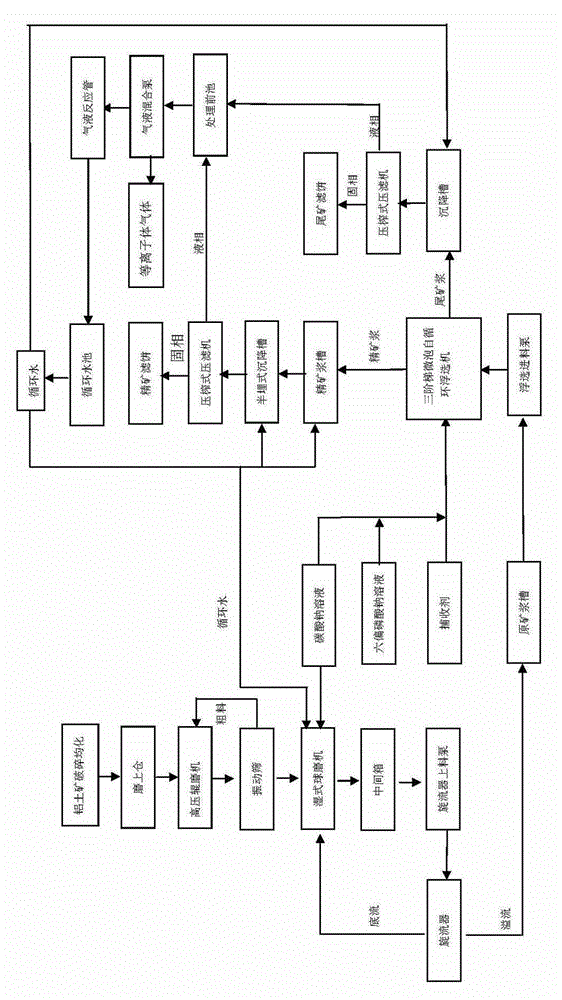

[0020] The following is attached figure 1 The specific implementation manner of the present invention will be described in further detail.

[0021] The present invention comprises the following steps:

[0022] (1) Crushing and homogenization of bauxite: After the bauxite waste residue is crushed by the bauxite crusher, it is sent to the mixing shed through the transfer belt, and the distribution trolley moves back and forth to distribute the material evenly, so that the silicon-aluminum ratio of the bauxite ( A / S) The deviation value is within ±0.3;

[0023] (2) Selective dissociation of bauxite: The crushed and homogenized bauxite enters the high-pressure roller mill through the upper chamber of the mill, and the ore powder after the roller mill passes through the vibrating screen, and the ore powder that cannot pass through the 6-mesh sieve is re-dissociated. After being rolled by a high-pressure roller mill, the ore powder that can pass through the 6-mesh sieve is metered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com