Precise dressing method of molding grinding wheel of grinding big-diameter bearing and flexible device thereof

A technology for forming grinding wheels and large diameters, which is applied in the field of bearing manufacturing, can solve the problems of small matching of grinding wheel dressing devices and low precision of grinding wheel dressing, and achieve the effects of avoiding step precision requirements, high cost performance, and reducing manufacturing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

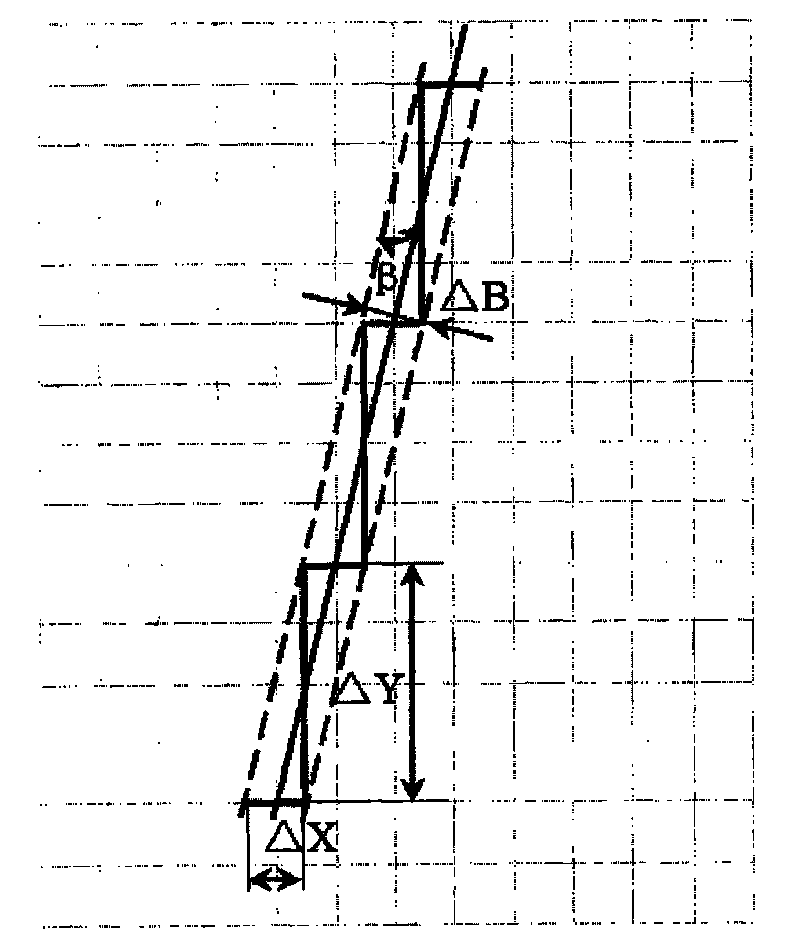

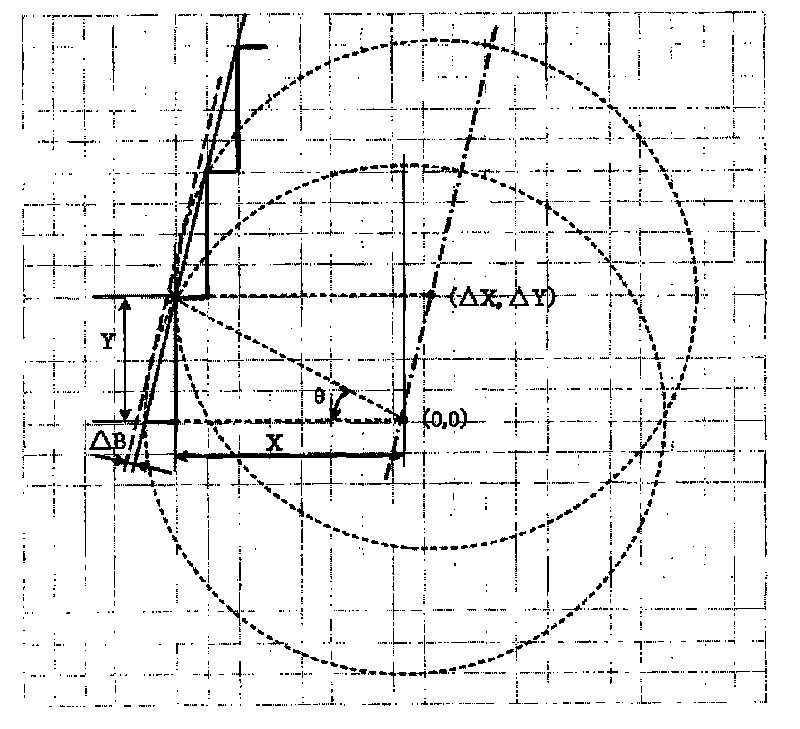

[0024] A precision dressing method for forming grinding wheels for grinding large-diameter bearings. The dressing track of the diamond pen is inserted according to the axial (X direction) and radial (Y direction) feed movement of the grinding wheel and the tangential (Z axis) swing around the grinding wheel. Complementary synthesis, the synthesis movement is controlled by PLC.

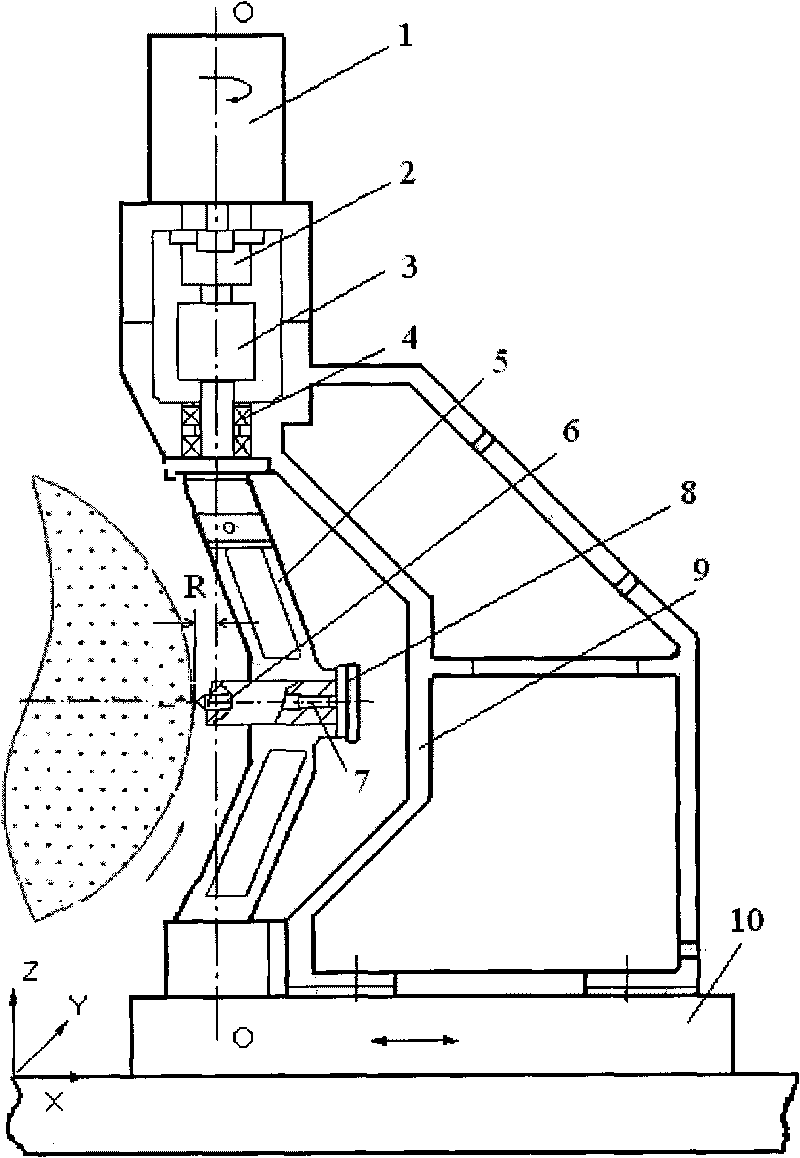

[0025] Such as figure 1 As shown in the figure, a flexible device supporting the precision dressing of a large-diameter bearing forming grinding wheel includes a servo drive motor 1, a harmonic reducer 2, a coupling 3, a bearing 4, a rotating shaft 5, an adjusting screw 7, a dial 8, and a support seat 9. The middle part of the rotating shaft 5 is equipped with an adjusting screw 7, the front end of the adjusting screw 7 is equipped with a diamond pen 6, and the rear is equipped with a dial 8. The lower part of the harmonic reducer 2 is connected to the rotating shaft 5 through the coupling 3, and the ...

Embodiment 2

[0053] The requirement of this embodiment is to adopt the configured grinding wheel dressing device of the ball bearing inner ring groove grinder (model is 3MB1330A) to grind a ball bearing with a diameter of 300mm and a curvature of the raceway arc of 1 / 60, so as to realize the device and Embodiment 1 is the same, and its main calculation and operation steps are as follows:

[0054] 1) Determine the single-step feed rate of the X-axis, let ΔX=1μm;

[0055] 2) Calculate the single-step feed of the Y axis, ΔY=ΔX / curvature of the raceway arc=60μm;

[0056] 3) Calculate the Z-axis swing angle θ, θ=arctg(ΔX / ΔY)=arctg(1 / 60)=arctg(0.0167)≤50″8′;

[0057] 4) Calculate the Z-axis swing radius R, R=ΔY2 / ΔX+ΔX=60 2 / 1+1=3601μm=3.601mm;

[0058] 5) Estimate the dressing error ΔB of the forming grinding wheel, ΔB=2RSin 2 (θ / 4)=2(3601)Sin 2 (50″8′ / 4)≤0.103μm;

[0059] 6) Check the dressing accuracy of the forming grinding wheel, that is, when ΔB≤T B / 3,T B is the contour tolerance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com