Beneficiation method for black and white tungsten fine deposit

A beneficiation method, the technology of black and white tungsten, applied in flotation, solid separation, etc., can solve the problems of low recovery rate and achieve the effects of low cost of chemicals, high recovery rate of tungsten, and simple recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

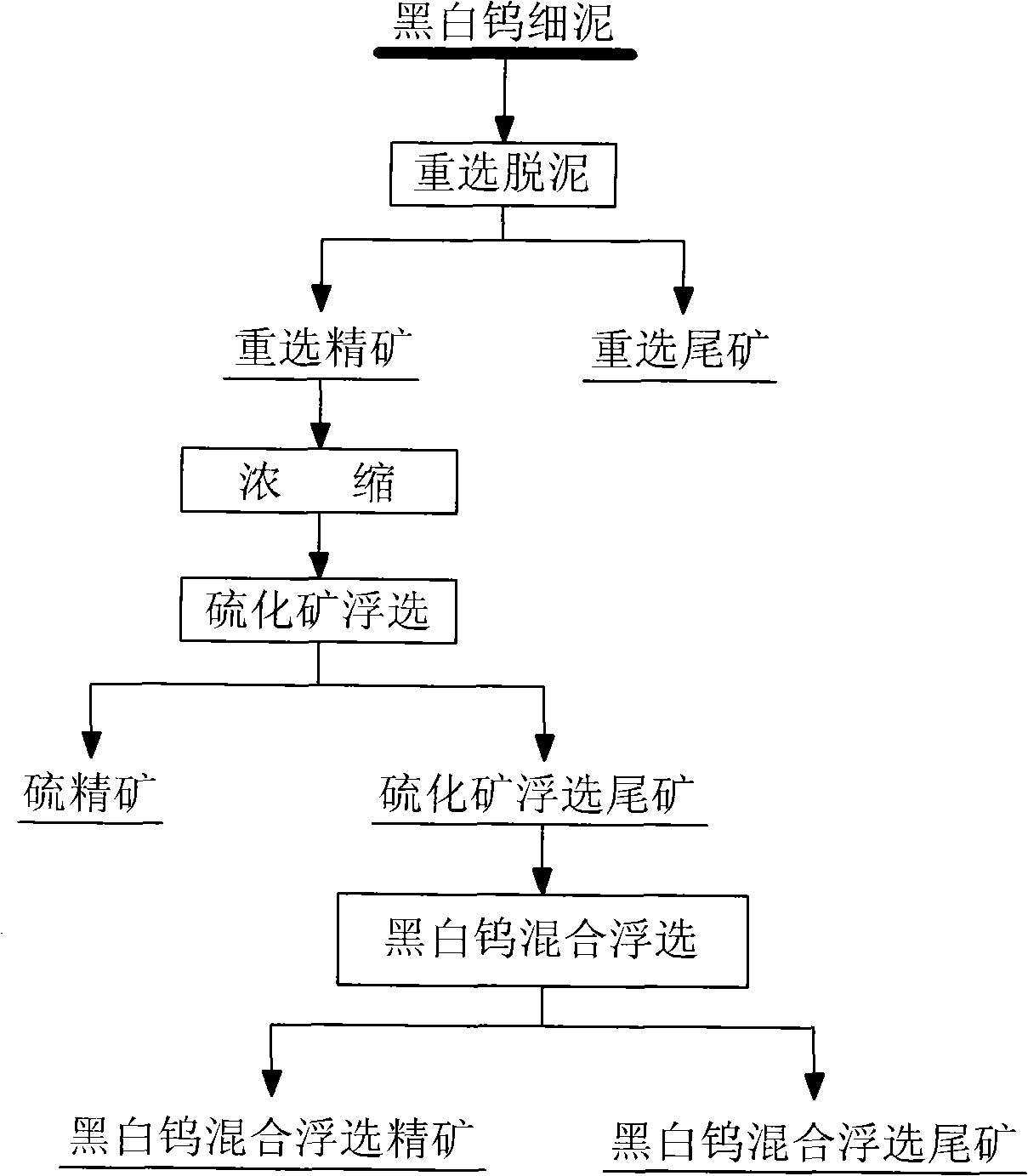

Method used

Image

Examples

Embodiment 1

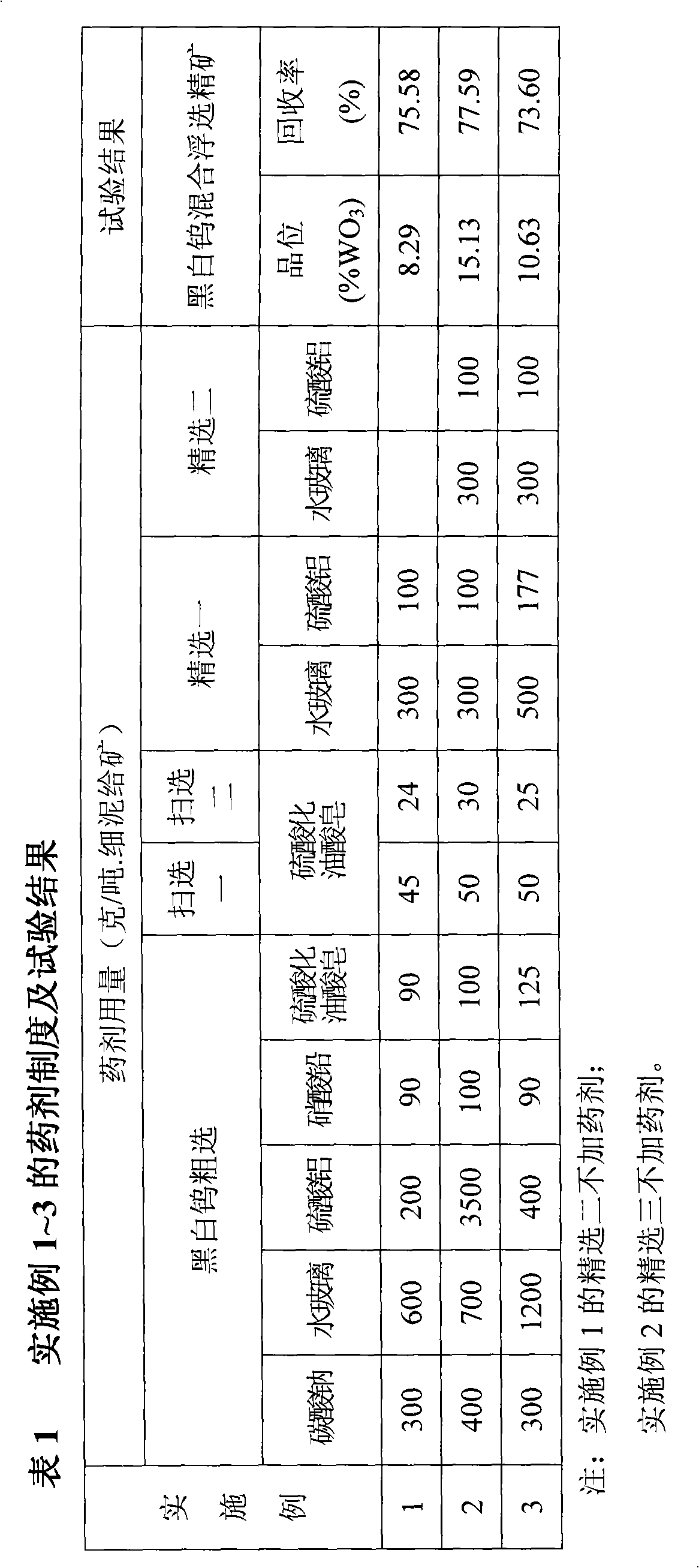

[0013] Black and white tungsten fine mud contains WO 3 0.37%, less than 30 micron particle size WO 3 The metal occupancy rate is 67%, and the ratio of black and white tungsten is 6:4. The black and white tungsten fine mud is deslimed by gravity separation, and the obtained gravity concentrate is concentrated to a concentration of 35% by a thickener, and then sulfide ore flotation is carried out. Sulfide ore flotation tailings were added with adjusting agents sodium carbonate, water glass, aluminum sulfate and lead nitrate according to the reagent system in Table 1, and stirred for 8 minutes. After adding collector sulfated oleic acid soap and stirred for 6 minutes, mixed flotation of black and white tungsten was carried out. After 1 rough selection, 2 selections, and 2 scans, the WO content is obtained. 3 8.29% black and white tungsten mixed flotation concentrate, the recovery rate is 75.58%.

Embodiment 2

[0015] Black and white tungsten fine mud contains WO 3 0.3%, less than 30 micron particle size WO 3 The metal occupancy rate is 73%, of which the black and white tungsten ratio is 6:4. The black and white tungsten fine mud is deslimed by gravity separation, and the gravity separation concentrate obtained is concentrated to a concentration of 33% by a thickener, and then sulfide ore flotation is carried out. Sulfide ore flotation tailings according to the pharmaceutical system in Table 1, add regulator sodium carbonate, water glass, aluminum sulfate, lead nitrate, stir for 6 minutes, add collector sulfated oleic acid soap and stir for 7 minutes, then mix black and white tungsten Flotation, after 1 roughing, 3 times of fine selection, 2 times of sweeping, to get the WO containing 3 15.13% black and white tungsten mixed flotation concentrate, the recovery rate is 77.59%.

Embodiment 3

[0017] Black and white tungsten fine mud contains WO 3 0.21%, less than 30 micron particle size WO 3 The metal occupancy rate is 81%, and the black and white tungsten ratio is 5:4. The black and white tungsten fine mud is first deslimed by gravity separation, and the obtained gravity concentrate is concentrated to a concentration of 30% by a thickener, and then subjected to sulfide ore flotation. Sulfide ore flotation tailings according to the pharmaceutical system in Table 1, add regulator sodium carbonate, water glass, aluminum sulfate, lead nitrate, stir for 10 minutes, add collector sulfated oleic acid soap, after stirring for 5 minutes, black and white tungsten Mixed flotation, after 1 roughing, 2 sweeps and 2 refinements, 10.63% WO was obtained 3 Black and white tungsten mixed flotation concentrate with a recovery rate of 73.60%.

[0018] It can be seen from Table 1 that for 0.10-0.50% WO 3 , less than 30 micron particle grade WO 3 Metal occupancy rate ≥ 60%, three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com