Ultrasonic laser composite dressing method for grinding wheel

A technology for dressing grinding wheels and lasers, which is applied to grinding/polishing equipment, abrasive surface adjustment devices, and parts of grinding machine tools, etc., and can solve problems such as excessive wear of dressing tools, low efficiency, and poor dressing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

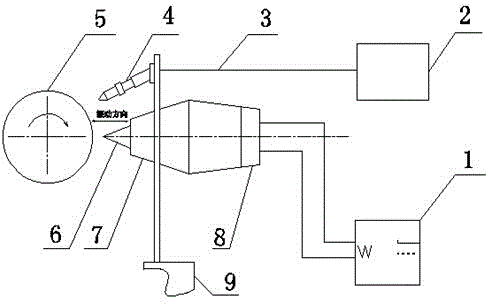

[0009] A grinding wheel ultrasonic laser composite dressing method, characterized in that: a laser transmitter 2 transmits energy to a laser focusing head 4 with a focusing head fixing adjustment device through an optical fiber 3, and the circumferential angle between the laser focusing head 4 and the diamond dressing pen 6 is set 50-70°, the axial distance is 0.6-2mm, the laser focusing head 4 moves and heats the rotating grinding wheel 5 axially in front of the dressing point with appropriate heating time and energy density, and the ultrasonic sounder 1 transmits the ultrasonic signal to The ultrasonic transducer 8 is converted into mechanical vibration by the transducer 8 and then transmitted to the horn 7. The wave of longitudinal vibration generated by the horn 7 will be decomposed at the chute at the small end, and divided into longitudinal vibration and bending vibration. The composite elliptical ultrasonic vibration is formed at the tip of the diamond dressing pen 6 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com