Composite dressing device

A technology of dressing device and spindle, which is applied in the direction of abrasive surface adjustment device, grinding machine parts, metal processing equipment, etc. It can solve the problems of not being able to shape and sharpen at the same time, the grinding wheel wears fast, and easily pollutes the environment, so as to improve the dressing Efficiency and dressing quality, accelerated grinding progress, and reduced cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

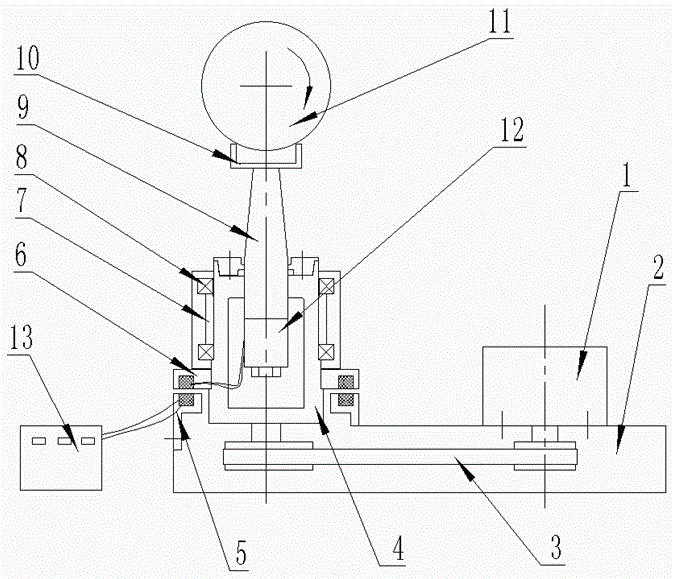

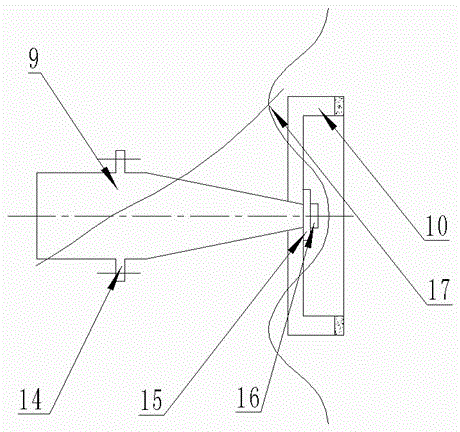

[0020] The embodiment of the composite dressing device in the present invention: figure 1 with figure 2 As shown, it includes a machine base 2 and a hollow main shaft 4 assembled on it. A pair of rolling bearings 8 spaced up and down is sleeved on the outer circumference of the hollow main shaft 4 so that the hollow main shaft 4 is rotated and assembled on the machine base through the rolling bearing 8 around a vertically extending axis. 2, and between the two rolling bearings 8 is provided with a bearing spacer 7 sleeved on the outer circumference of the hollow main shaft 4, so as to maintain the relative position of the two rolling bearings 8 through the bearing spacer 7. The bottom of the hollow main shaft 4 is connected to a driving motor 1 through a transmission belt 3, and the driving motor 1 is fixed on the right side of the machine base 2.

[0021] A wireless power transmission device is also installed between the hollow main shaft 4 and the base 2. The wireless power tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com