A polishing finisher

A dresser and polishing technology, applied in the field of polishing dressers, can solve the problems of decreased binding force, fall off, and cannot really solve the problem of abrasive particles, and achieve the effect of solving the falling off of abrasive particles and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

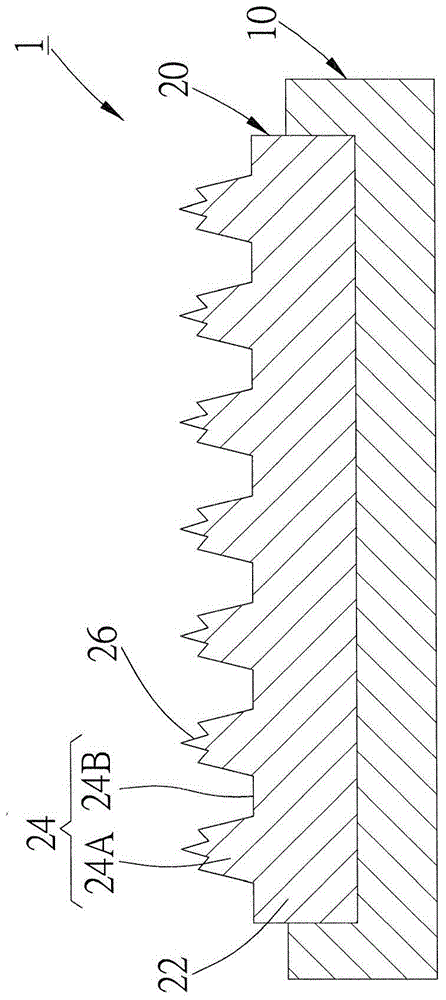

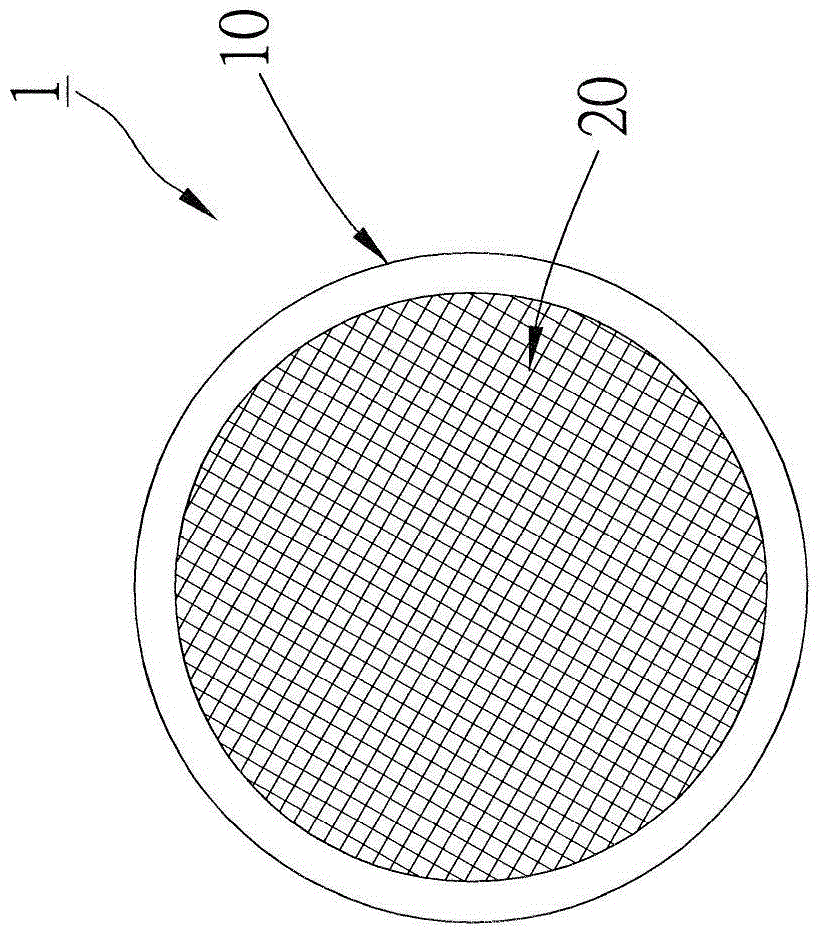

[0031] In order to illustrate the present invention more clearly, a preferred embodiment is given and detailed description is as follows in conjunction with the drawings, please refer to Figure 1 to Figure 4 As shown, a polishing conditioner 1 according to a preferred embodiment of the present invention includes a base 10 and a sapphire polishing pad 20 .

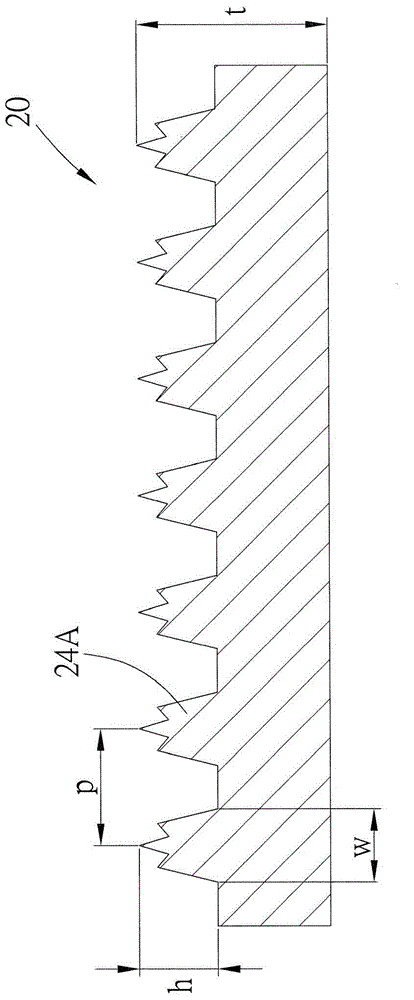

[0032] The crystal structure of the sapphire polishing pad 20 of the polishing trimmer 1 is a single crystal, twin crystal or polycrystalline structure, and includes a root portion 22 and a grinding layer 24, and the root portion 22 is brazed, glued or tenoned The abrasive layer 24 is fixed on the base 10 in a manner, and includes a plurality of protrusions 24A and a plurality of recesses 24B.

[0033] In this embodiment, the surface of each protrusion 24A is further formed with a microstructure 26 with a surface roughness ranging from 0.1 to 5 micrometers (μm), and the microstructure 26 is made by yellow light lithography...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com