Plane contour grinding center of door-shaped vertical mill

A technology of plane profile and grinding center, which is applied in the direction of machine tools, grinding racks, and grinding beds suitable for grinding workpiece planes, and can solve problems such as inconvenient use and low efficiency of grinding wheel dressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

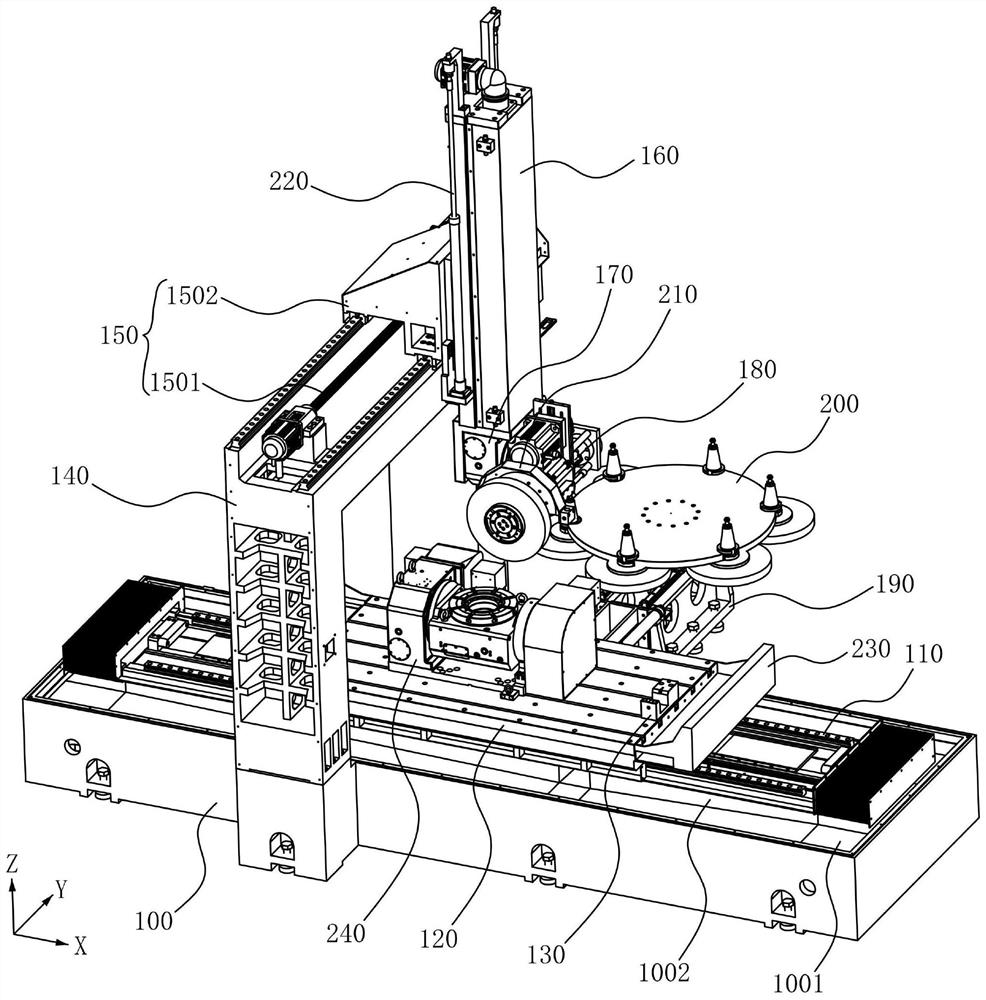

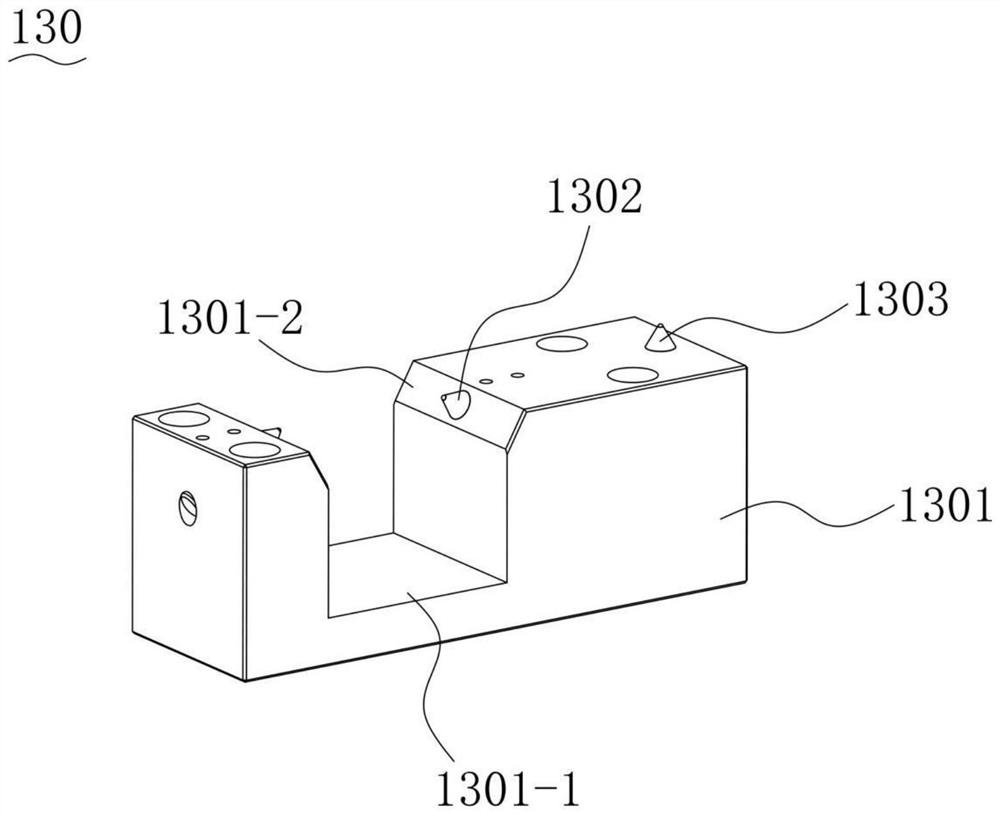

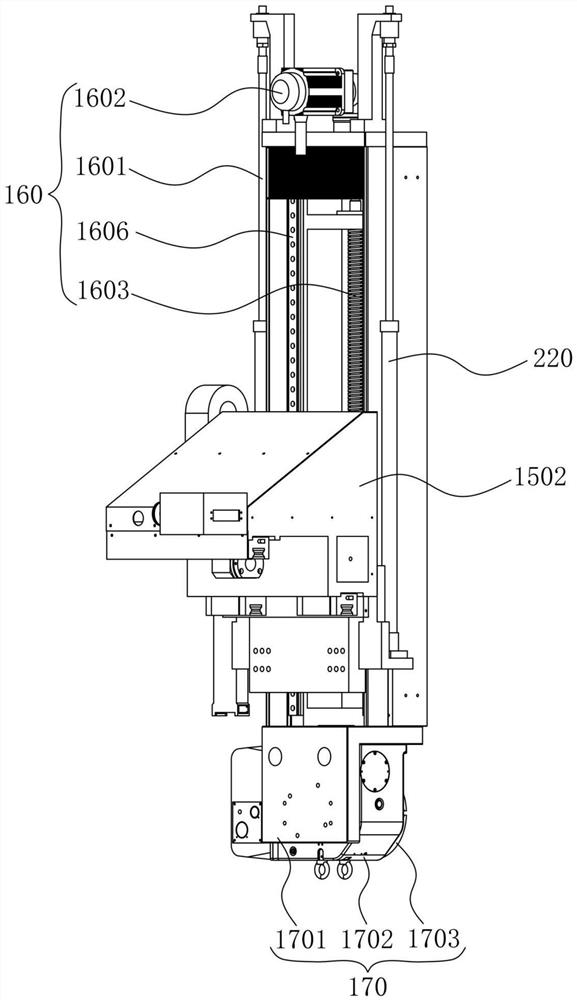

[0026] Please refer to figure 1 , a gantry-type vertical grinding plane profile grinding center, including a cross-shaped bed 100, an X-axis feed device 110, a workbench 120, a sand repair device 130, a gantry frame 140, and a Y-axis feed device 150 , Z axial feed device 160, automatic angle adjustment device 170, automatic tool change electric spindle 180, Y axial drive device 190 and grinding wheel tool magazine 200, X axial feed device 110 is installed on the bed 100, the workbench 120 is installed on the X-axis feeding device 110, the sand repairing device 130 is installed on the workbench 120, the gantry frame 140 is installed on the bed 100, the Y-axis feeding device 150 is installed on the gantry frame 140, and the Z-axis The feed device 160 is installed on the Y-axis feed device 150, the automatic angle adjustment device 170 is installed on the Z-axis feed device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com