Device for measuring wall or ground flatness by lasers

A laser measurement and flatness technology, applied in the field of laser measurement, can solve the problems of inability to meet the flatness control of the measured surface, high cost, poor measurement accuracy and cannot be repaired by the measured surface, etc., to improve the measurement and repair efficiency and easy to carry. , the effect of improving monitoring and trimming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

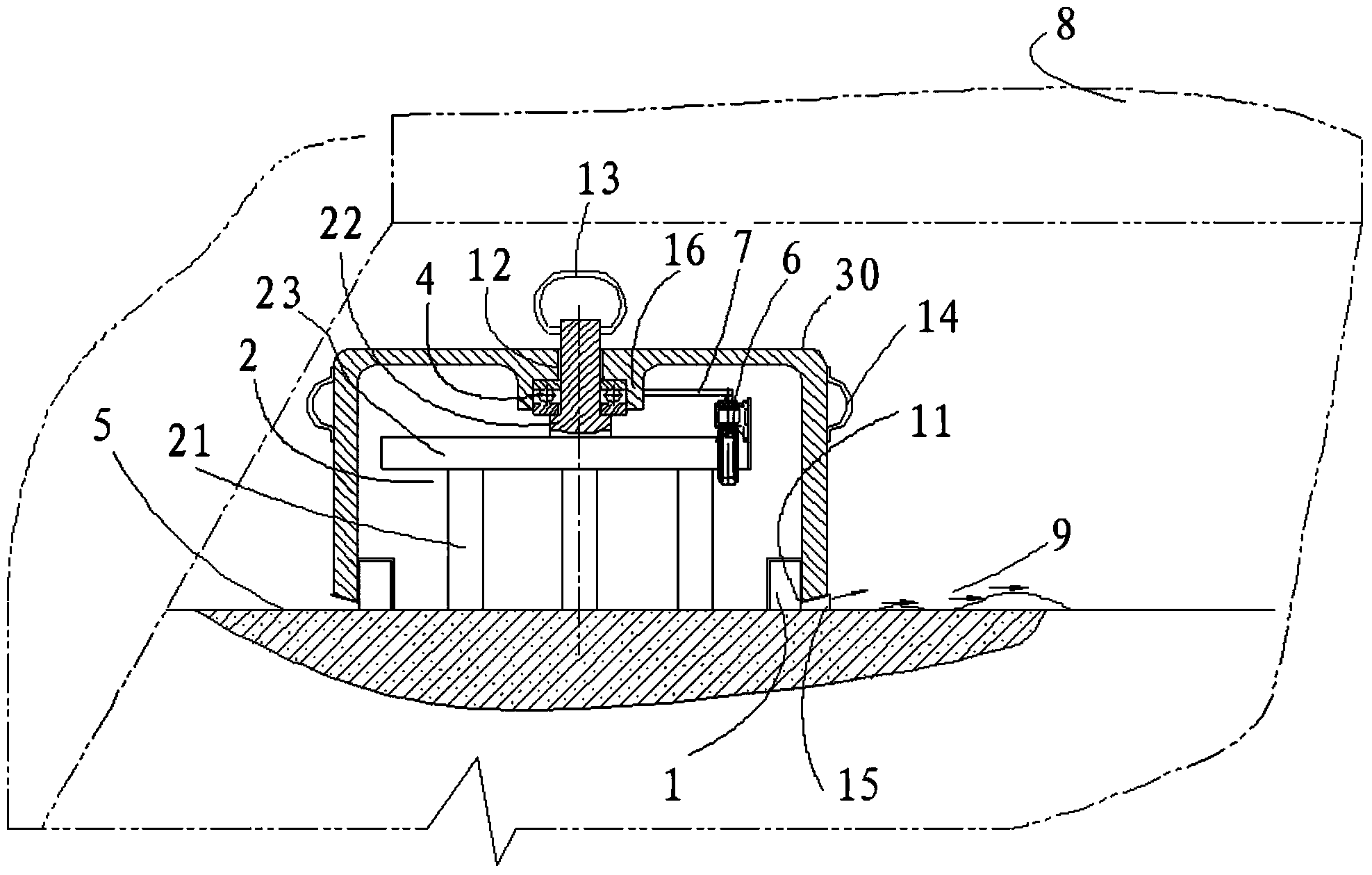

[0028] Such as figure 1 As shown, a device for measuring the flatness of a wall or ground by using a laser includes a base 2 and a laser transmitter 1, the laser transmitter 1 is connected to a laser fixing seat 30, and the lower part of the base 2 is supported on a standard support surface 5 , the standard support surface 5 is a plane with qualified flatness after local leveling and grinding, and the laser emission point 11 of the laser transmitter 1 is located at the lower part of the laser fixing seat 30 and is located in the standard support surface plane 5; A stepped shaft 22 is provided in the middle of the upper part of the base 2, a thrust ball bearing 4 is provided at the small shaft of the stepped shaft 22, a boss 16 is provided on the upper part of the laser transmitter 1, and a stepped hole 12 is provided on the boss 16, so The large hole of the stepped hole 12 cooperates with the thrust ball bearing 4, and the laser emitter 1 rotates around the axis of the stepped...

Embodiment 2

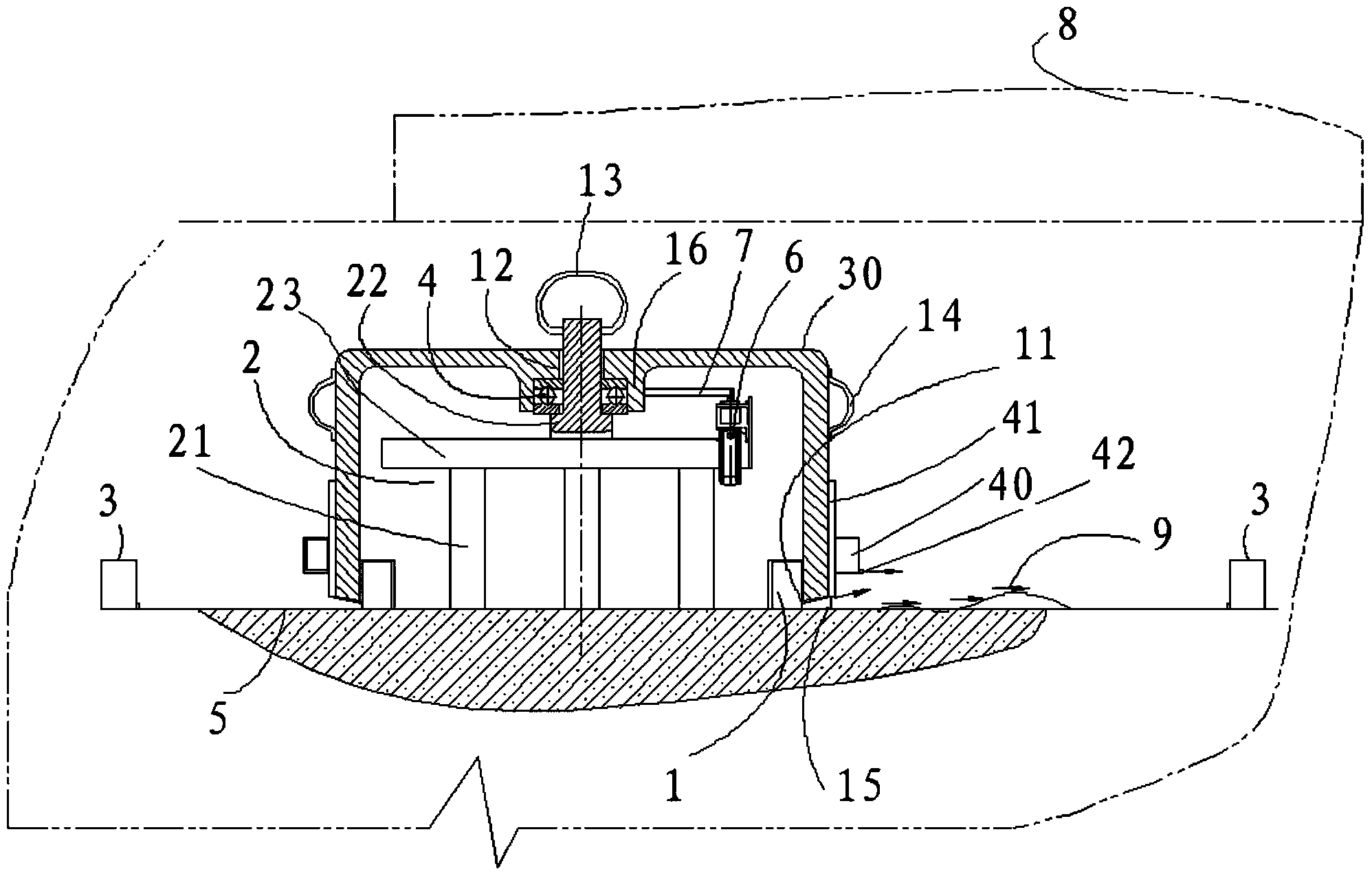

[0035] Such as figure 2 As shown, it is the state when the present invention measures the flatness of the horizontal plane. A laser receiver 3 is arranged around the measured plane, and the receiving point of the laser receiver 3 is located in the standard supporting surface.

[0036] A second laser emitter 40 is provided on the laser mount 30 on the top of the laser emitter 1, and the second laser emitter 40 is connected to the laser mount 30 through a second connecting seat 41 fixed on the outer surface of the laser mount 30. The second connecting seat 41 is provided with a vertical lead screw guide rail, the second laser emitter 40 is provided with a nut, and the second laser emitter 40 moves on the second connecting seat 41 along the guide rail through the cooperation of the lead screw and the nut. The laser beam emitted by the second laser emitter 40 is a straight horizontal parallel light, and the emission port 42 of the second laser emitter 40 is arranged at the bottom...

Embodiment 3

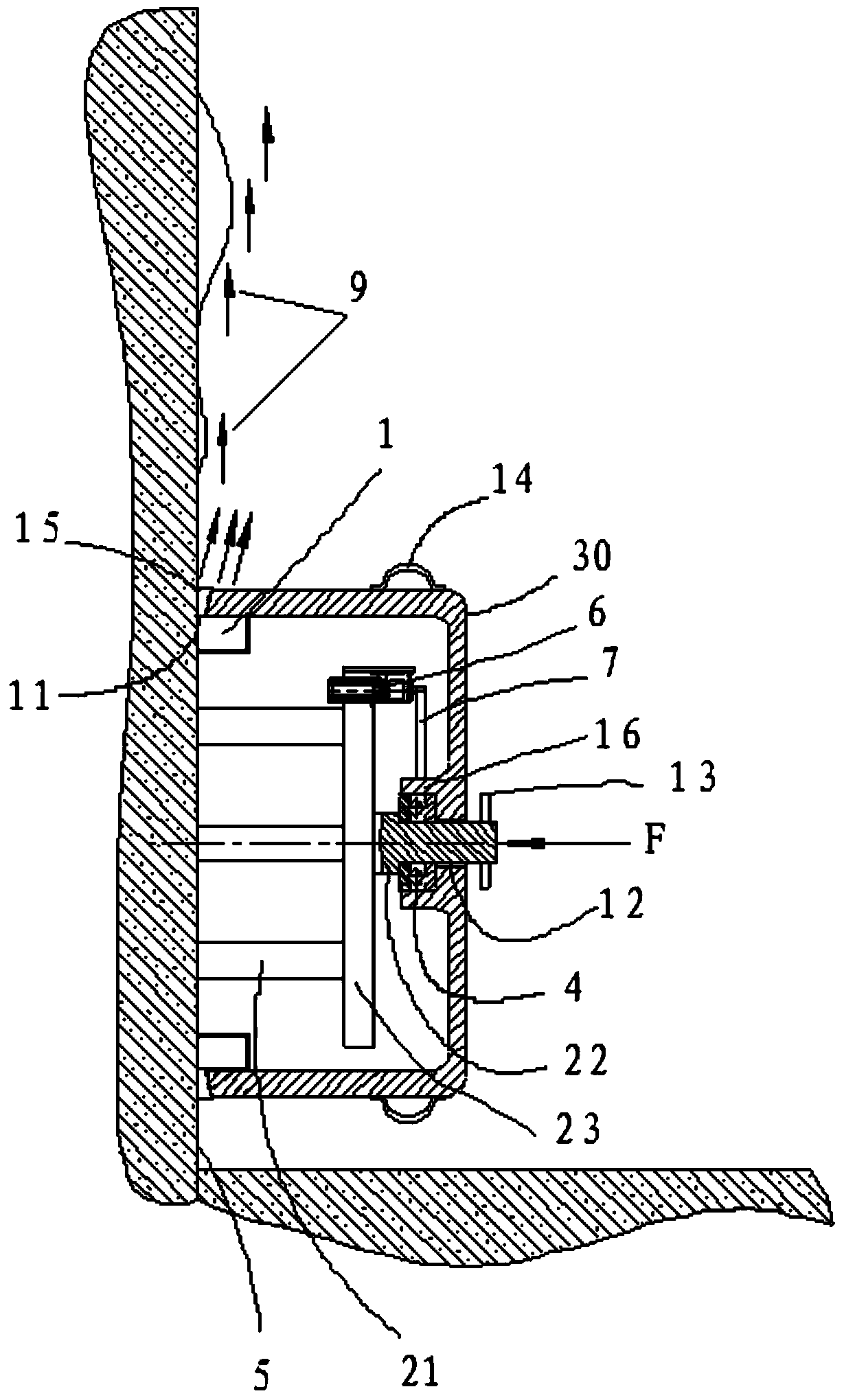

[0039] Such as image 3As shown, it is the state when the present invention measures the flatness of the vertical wall surface. When in use, a force F is applied to the base through the small shaft end of the stepped shaft, so that the supporting feet of the base are in contact with the wall surface, and the whole machine is prevented from falling to the ground. On the ground, turn the laser transmitter to measure the flatness of the measured surface.

[0040] The use method of the present invention: when measuring the flatness of the plane, install the laser emitter and the base, place the base on the ground, use the horizontal air bubble to detect the position of the laser emitter and the placed ground, and adjust the position of the base so that the horizontal air bubble is in the center Position, if the horizontal air bubble deviates from the center position, make the air bubble in the center position by grinding the flatness of the ground at the installation position, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com