Wheel truing device

一种砂轮修整、砂轮的技术,应用在磨料表面调节装置、磨床、磨削机床的部件等方向,能够解决降低生产率、增加砂轮修整所需的时间等问题,达到提高修整效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

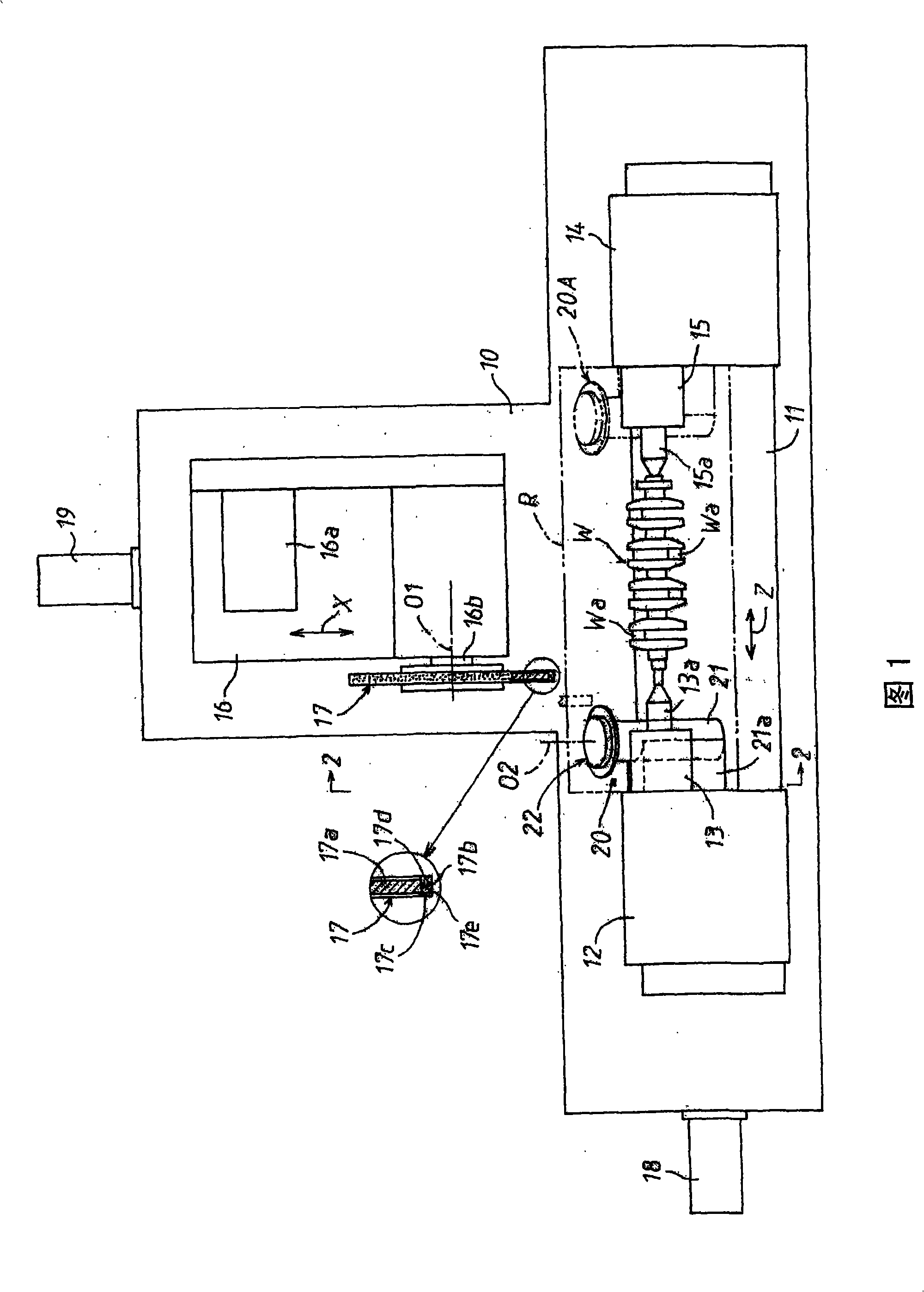

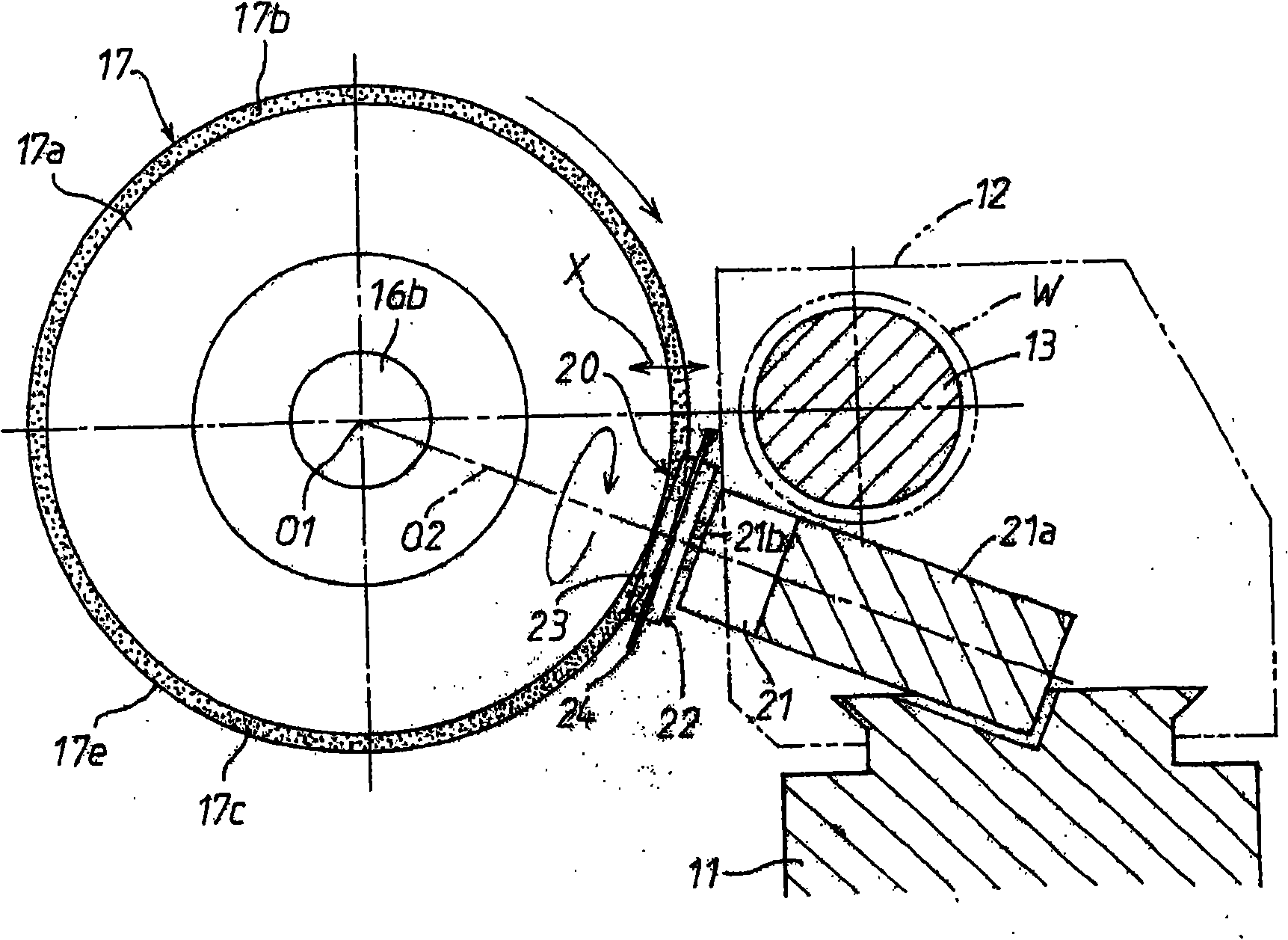

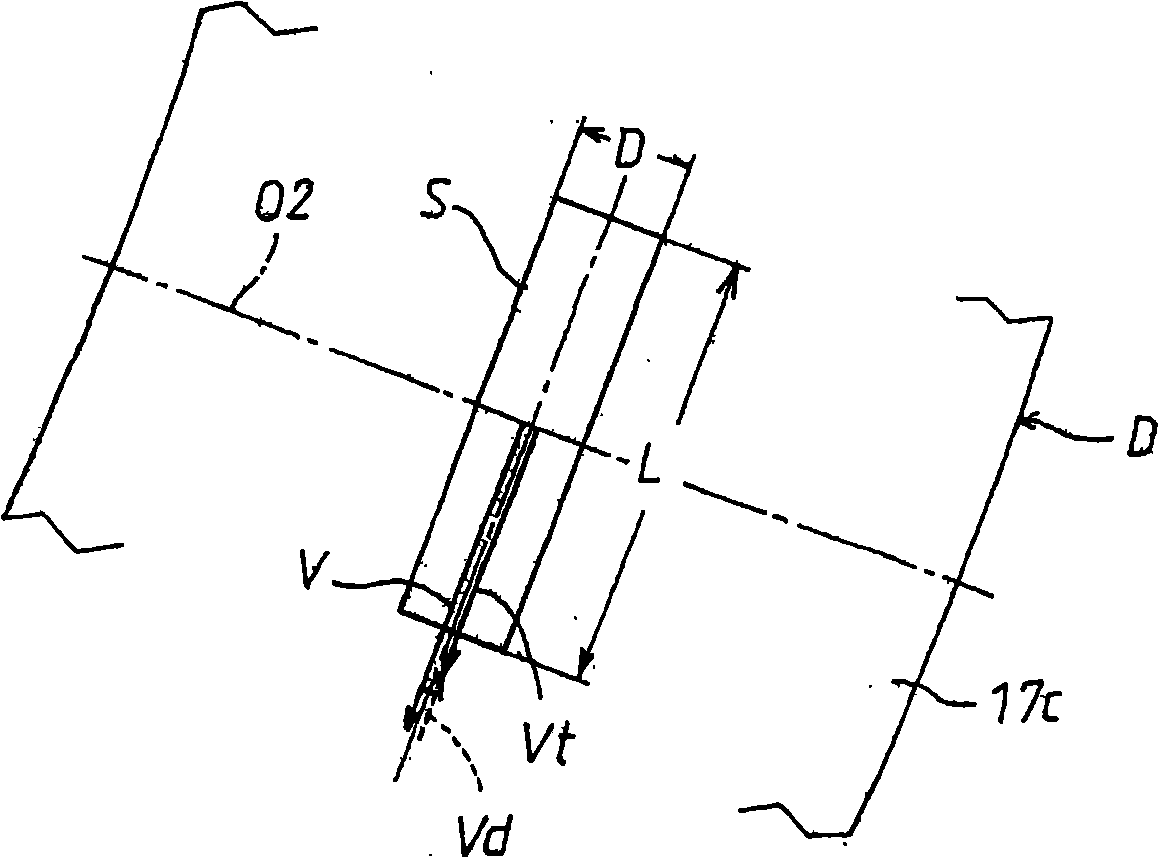

[0021] Below, refer to Figure 1- image 3 , the first embodiment of the dressing device according to the present invention will be described. FIG. 1 is a plan view showing the overall configuration of a cylindrical grinder including a dressing device according to the first embodiment. figure 2It is an enlarged sectional view along line 2-2 in Fig. 1. As shown in Figure 1, the processing part table 11 that is guided and supported by the grinding machine table 10 of the cylindrical grinder and can move along the horizontal left and right direction (Z direction) is driven by the Z-axis motor 18 to reciprocate. 11 is fixed opposite to the Z direction: the main shaft seat 12 bearing the main shaft 13 having a rotation axis parallel to the Z direction, and the tailstock that supports the top sleeve 15 coaxially arranged with the main shaft 13 and enables it to advance and retreat Seat 14. Both ends of the machining member W (the crankshaft of the internal combustion engine in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com