Jacquard weave cut velvet and processing method thereof

A jacquard cut velvet cloth and processing method technology, which is applied in the processing of textile materials, mechanical cleaning, high-pressure cleaning, etc., can solve the problems of short use time, shortened use time, and no processing method, etc., to achieve convenient carding and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

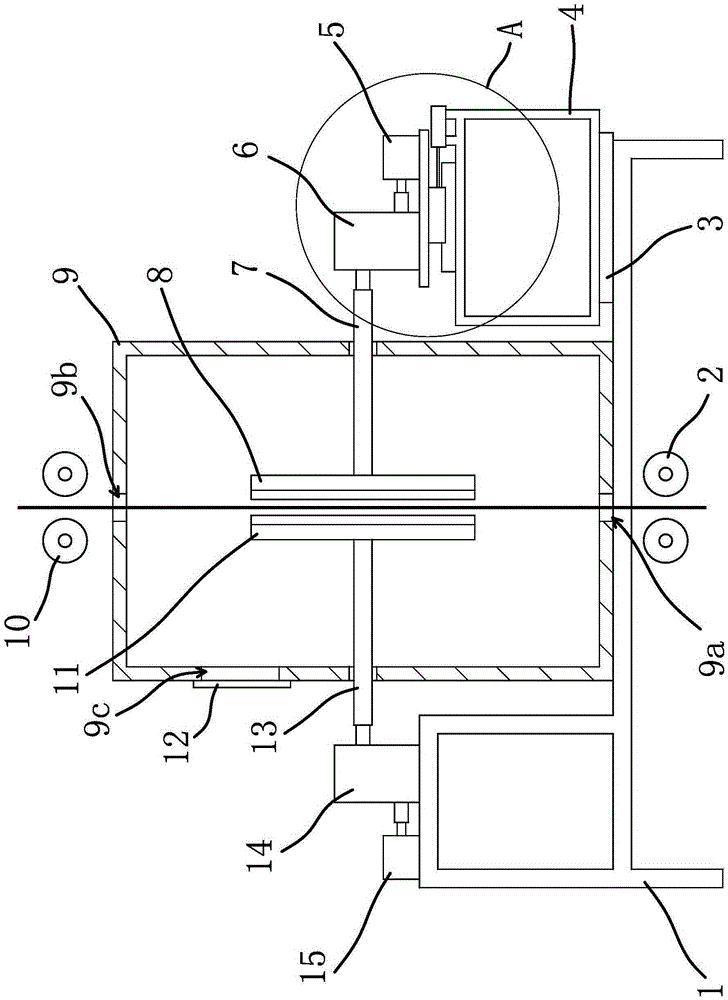

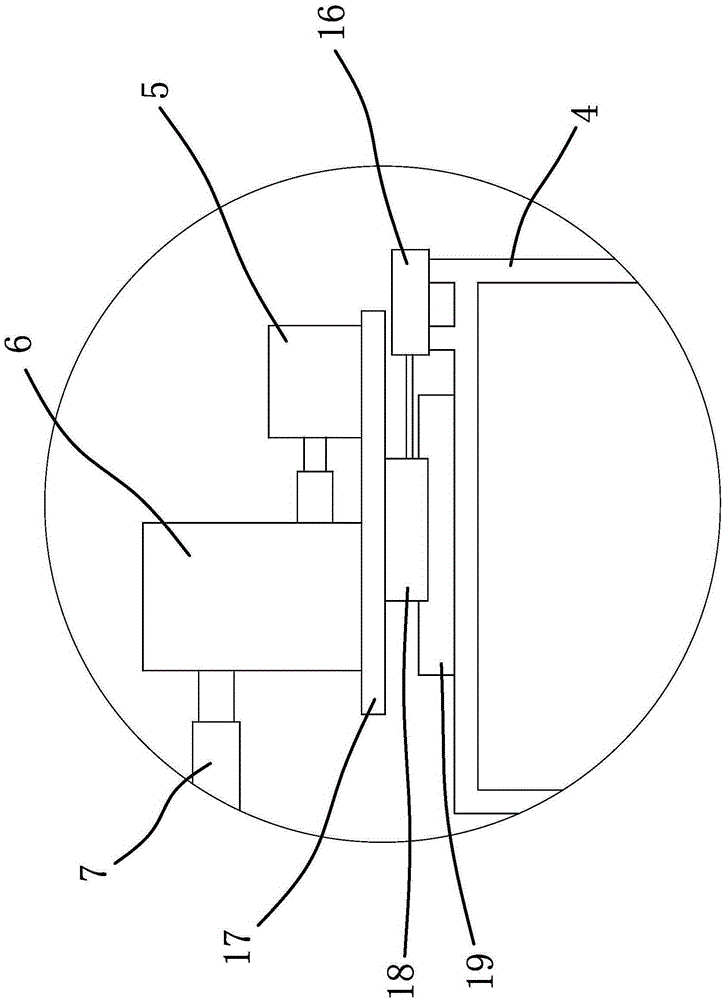

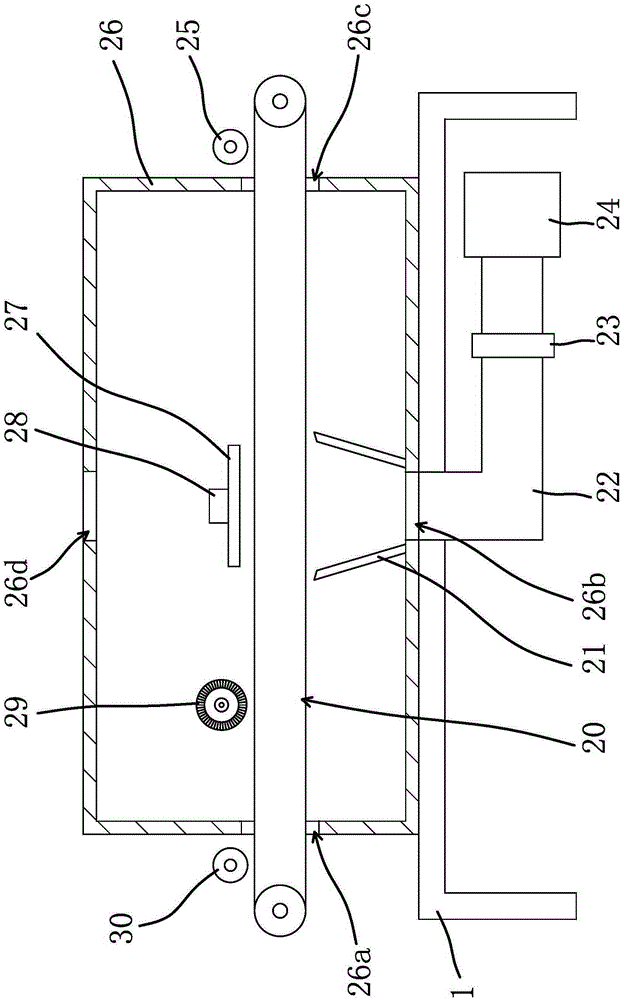

[0084] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0085] The jacquard cut velvet fabric comprises a flannelette layer on which a protective layer is fixed, and the protective layer is composed of the following components in parts by weight: 35-50 parts of polyurethane resin, 5-8 parts of antistatic agent, and 0.6-5 parts of anti-fungal agent 1.8 parts, 0.5 to 2 parts of detergent, 2 to 4 parts of crosslinking agent and 20 to 25 parts of toluene; -5, The detergent resistance is trimethylolpropane isopolymer, and the crosslinking agent is benzoyl peroxide.

[0086] The parts by weight of each component are as follows: 43 parts of polyurethane resin, 6 parts of antistatic agent, 1.2 parts of antifungal agent, 1.2 parts of detergent resistance, 3 parts of crosslinking agent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com