Photocuring 3D printing SiCN ceramic precursor material and application thereof

A ceramic precursor, 3D printing technology, used in ceramic molding machines, additive processing, manufacturing tools, etc., can solve the problems of reduced printing accuracy, influence of ceramic performance, difficult to control curing thickness, etc., to improve printing accuracy and toughness. , the effect of good mechanical properties and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add solid polysilazane ceramic precursor, liquid polycarbosilane precursor, and n-hexane in a weight ratio of 50:15:25, stir at room temperature for 4 hours until the solid polysilazane precursor is fully dissolved, and obtain a modulated liquid precursor Then by modulation liquid precursor: the ratio of acrylic acid active monomer weight ratio is 3:1 to add acrylic acid active monomer, the weight ratio of hexanediol diacrylic acid and pentaerythritol triacrylate in the acrylic acid active monomer is 2:1, finally Add 1% photoinitiator, 0.5% carbon nanotube light absorber, 1% leveling agent and defoamer according to the total mass percentage of all added components, and stir overnight at room temperature.

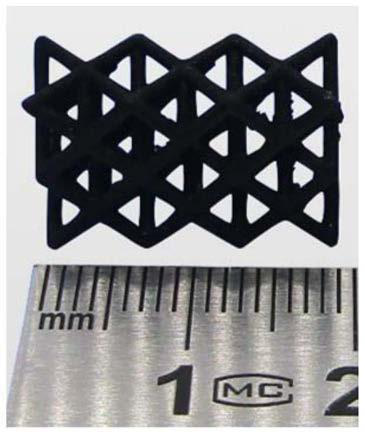

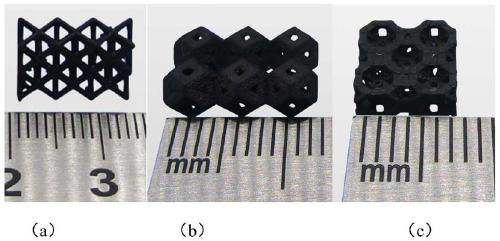

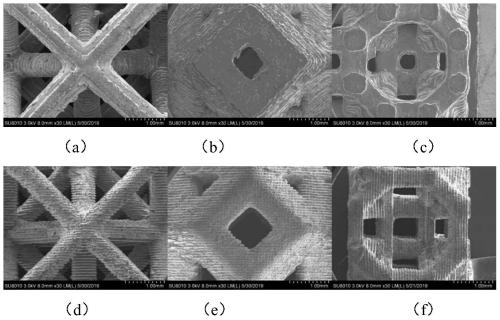

[0042] Transfer the configured photocurable precursor material to the resin tank of the photocurable 3D printer, import the periodic lattice structure model, set the printing layer thickness to 50 microns, and the printer is under the control of the designed printing p...

Embodiment 2

[0046] Add solid polysilazane ceramic precursor, liquid polycarbosilane precursor, and n-hexane in a weight ratio of 50:15:25, stir at room temperature for 4 hours until the solid polysilazane precursor is fully dissolved, and obtain a modulated liquid precursor Then by modulation liquid precursor: the ratio of acrylic acid active monomer weight ratio is 3:1 to add acrylic acid active monomer, the weight ratio of hexanediol diacrylic acid and pentaerythritol triacrylate in the acrylic acid active monomer is 2:1, finally Add 1% photoinitiator, 0.1-0.7% carbon nanotube light absorber, 1% leveling agent and defoamer according to the total mass percentage of all added components, and stir overnight at room temperature.

[0047] Transfer the photocurable precursor materials with different contents of carbon nanotube light absorbers to the resin tank of the photocurable 3D printer, and irradiate them for 0-20s respectively, and the thickness changes as follows: Figure 5 As shown, (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com