Support structure generation method and device, electronic equipment and storage medium

A technology of support structure and support area, which is used in electrical digital data processing, computer-aided design, details involving 3D image data, etc. It can solve the problem of low printing success rate, achieve uniform distribution, simplify the calculation process, and avoid leakage Check the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Exemplary embodiments of the present application are described below in conjunction with the accompanying drawings, which include various details of the embodiments of the present application to facilitate understanding, and they should be regarded as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the application. Also, descriptions of well-known functions and constructions are omitted in the following description for clarity and conciseness.

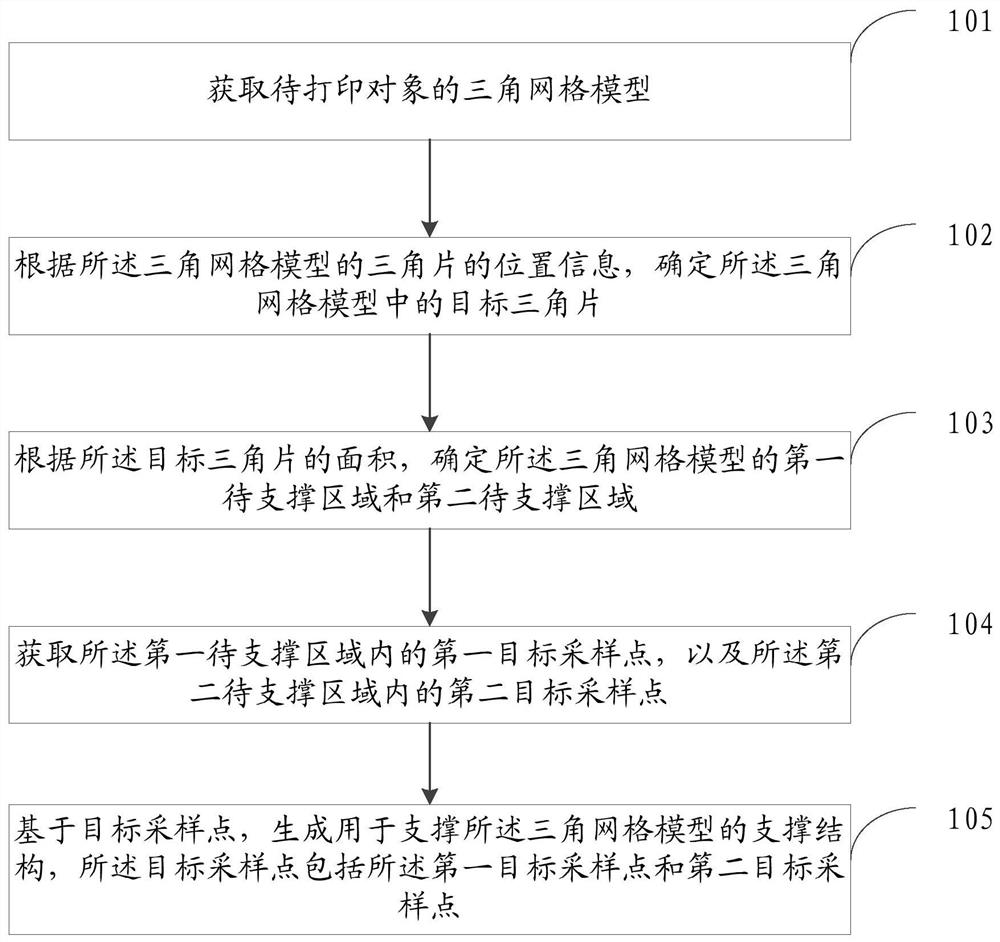

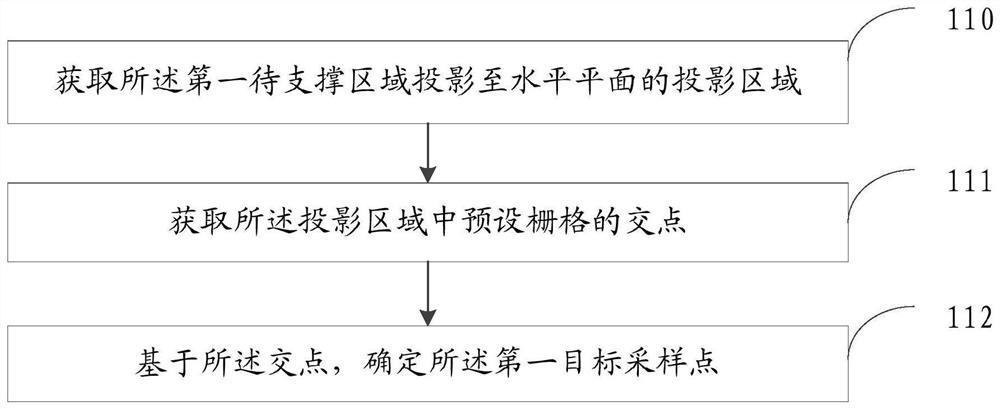

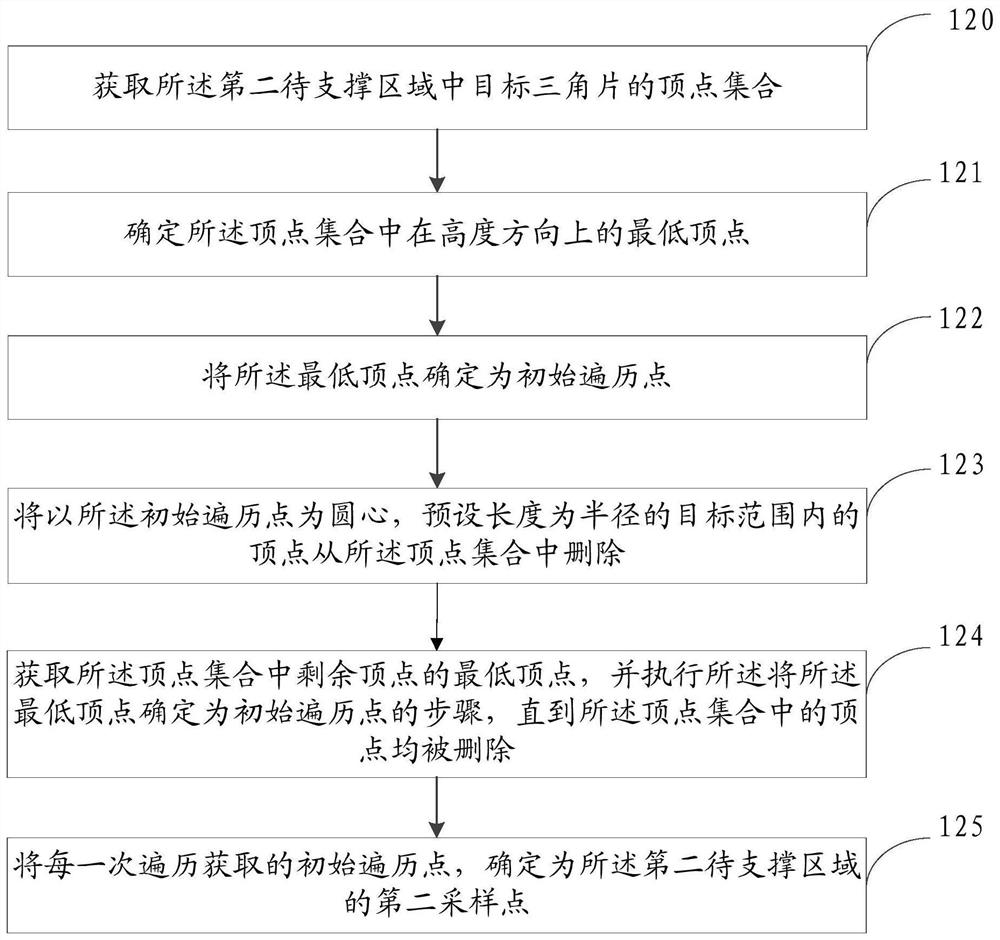

[0035] see figure 1 , figure 1 is one of the flow charts of the supporting structure generating method provided by the embodiment of the present application, such as figure 1 As shown, this embodiment provides a method for generating a support structure, including the following steps:

[0036] Step 101, acquiring a triangular mesh model of an object to be printed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com