Baseplate of 3D printer

A 3D printer and bottom plate technology, applied in the processing platform/substrate, additive processing, etc., can solve the problems of affecting the flatness of the printing bottom plate surface, affecting the printing effect of 3D printing, and troublesome use, so as to prevent the adhesion from being too tight and improve The effect of printing success rate and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

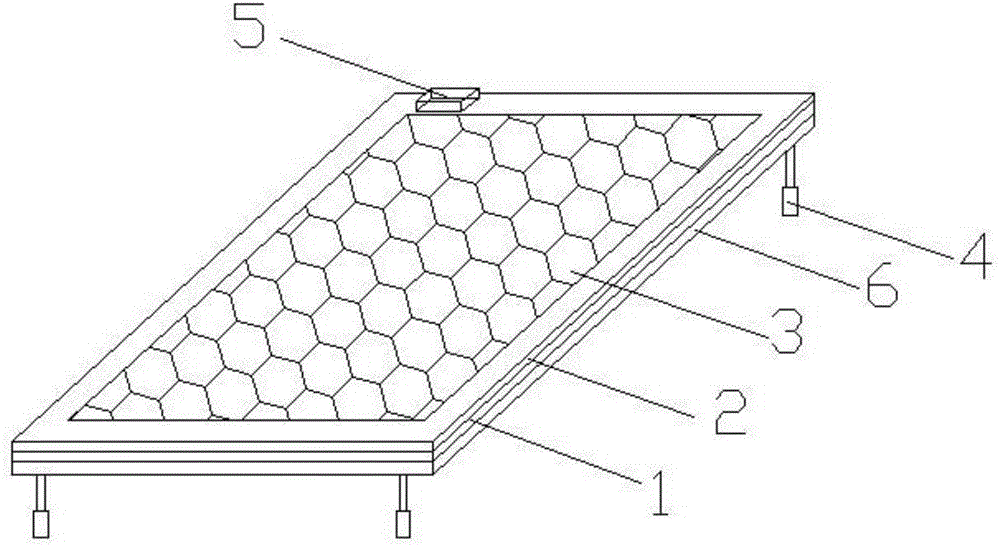

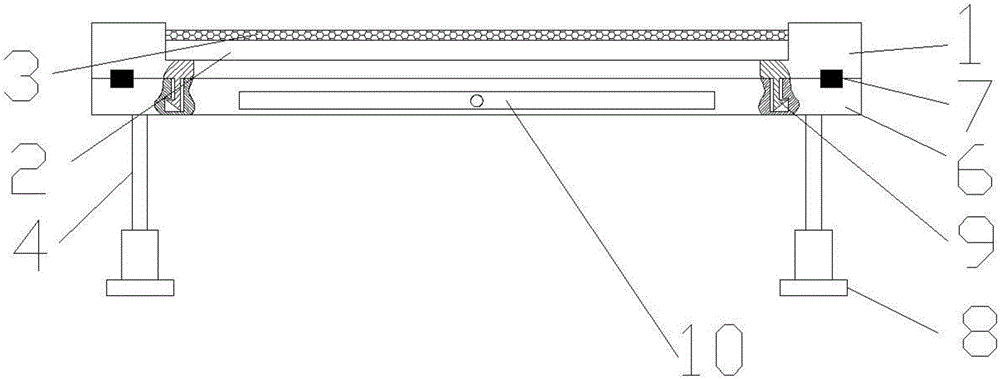

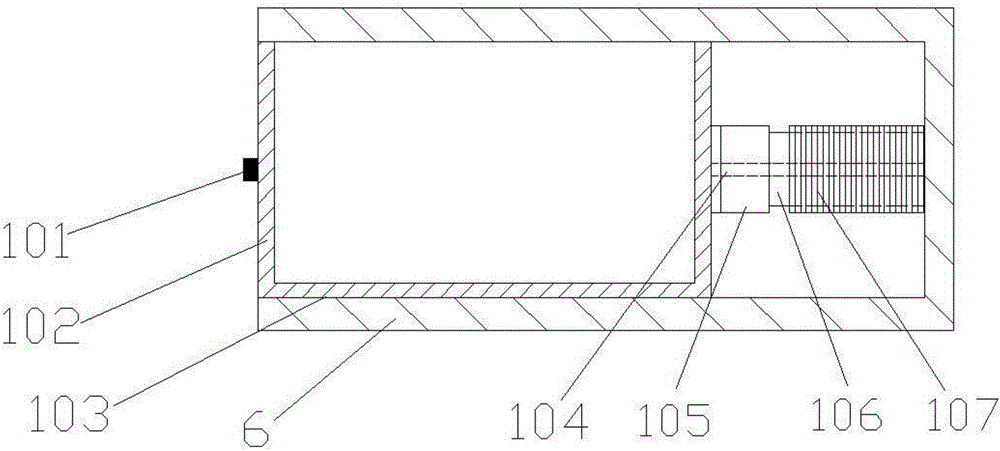

[0022] figure 1 A specific embodiment of the present invention is shown: a bottom plate of a 3D printer, including a connecting plate 6, a PC board 1, a hot-melt adhesive layer 2, an anti-sticking pattern 3, a hydraulic telescopic rod 4, a level 5 and an automatic drawer device, and a PC board 1 It is the main body of the bottom plate; the connecting plate 6 is arranged on the lower surface of the PC board 1, and the lower surface of the inner cavity of the connecting plate 6 is symmetrically provided with two slide grooves. Both the connection board 6 and the PC board 1 are provided with a magnet 7, and the two are connected by magnetic force. The lower surface of the PC board 1 is provided with a buckle 9, which is connected and fixed with the connection board 6 through the buckle 9. The hot-melt adhesive layer 2 is adhered to the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com